TECHNICAL NOTE

31

3

4

18/07/14

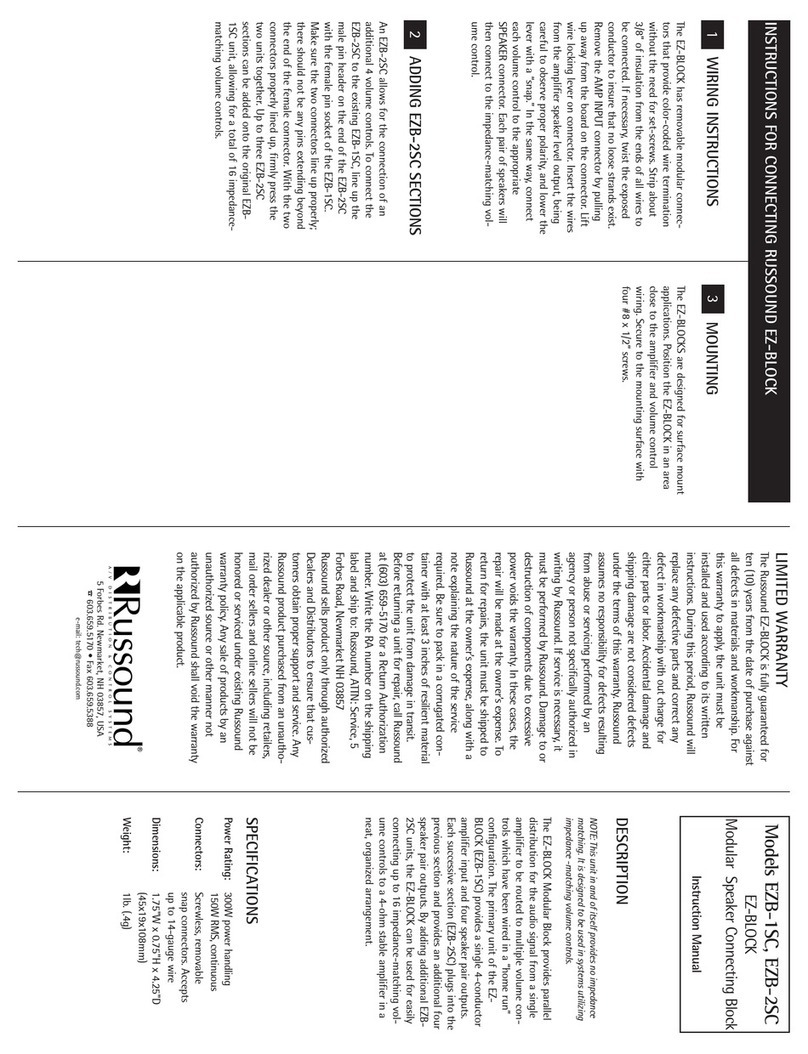

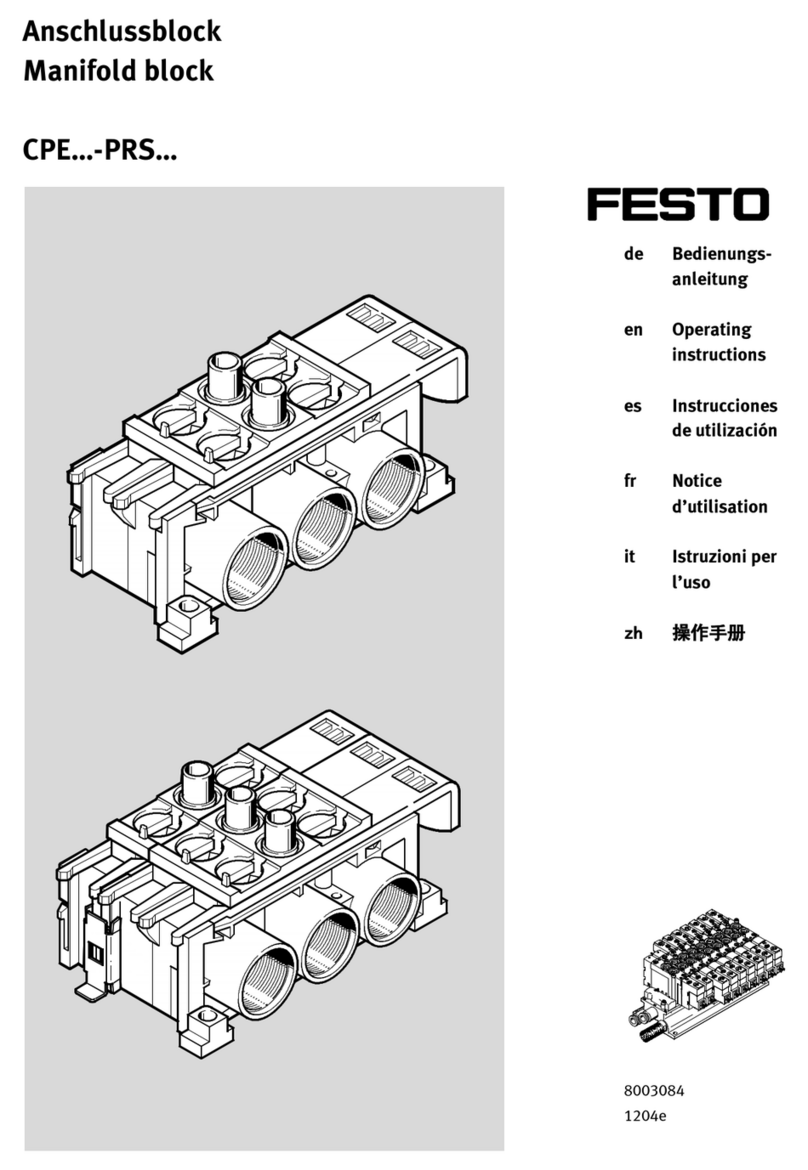

Fig. A

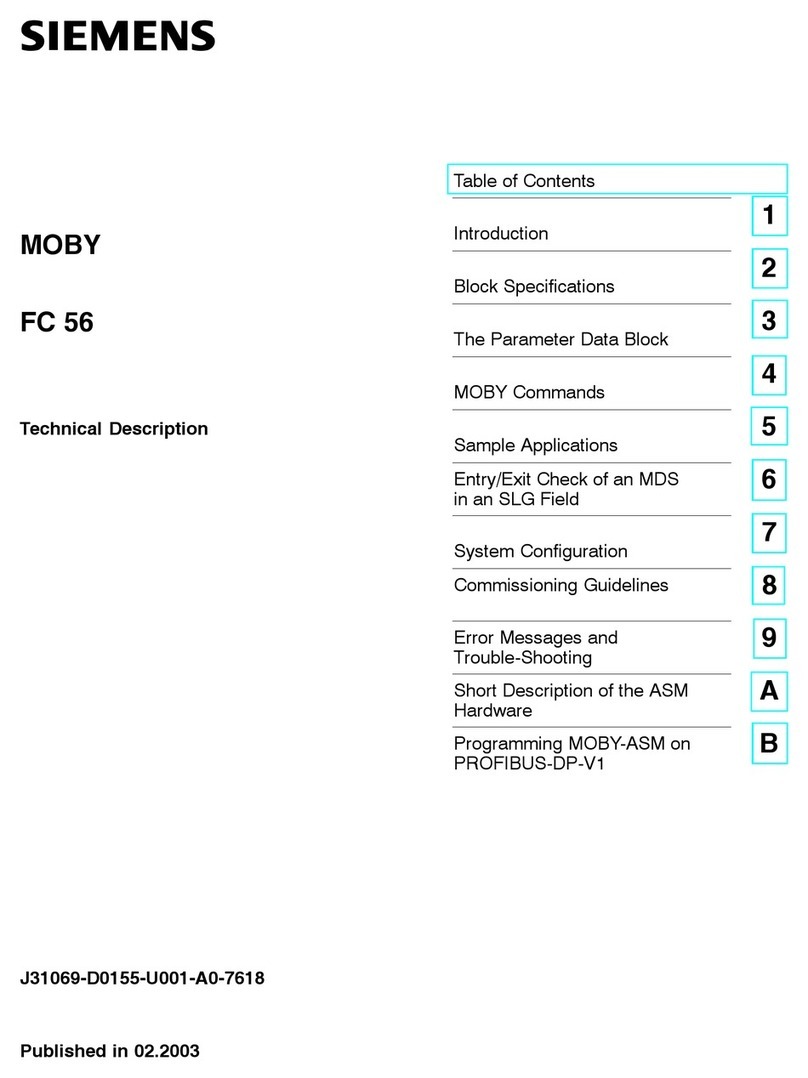

Fig. B

POSITION COMPONENT

TERMINAL BLOCK

STRIPPING LENGTH

[ mm ]

TORQUE

[ Nm ] (*)

1 Insulating body DBC.2 9 0,4

2 Upper conducting body

3 Lower conducting body

4 Tightening screw

5 Wire clamping collar

Note(*): values taken from Table 4 of IEC 60947-1 Std.

Cabur terminal block type DBC.2 allows the direct and anti-loosening connection of solid, stranded and flexible conductors, by

means of wire clamping collars, captive screws and conducting body.

Each clamping unit shall house only one conductor

The insertion of the cable is eased by:

•Sloping entrance planes provided on the insulating body

•A tab provided in the collar that avoids faulty introduction of the conductors

•Adequate dimensioning of the conductors insertion hole, with respect to the diameter of the maximum connectable conductor

(according to the different Gauges prescribed by IEC 60947-1Std.)

Appropriate grooving, provided in the wire clamping collar and on the conducting body guarantee a perfect electrical contact and an

efficient blocking of the conductor. Both the wire clamping collar and the tightening screw are manufactured in tempered steel with

galvanic RoHS conforming zinc plating; thanks to their coupling it is possible to apply the correct contact pressure

By acting on the tightening screw, the collar tightens the conductor against the conducting body, which is manufactured in tin-plated

copper. With the clamping yoke tightening system a gas proof, particularly safe connection is guaranteed

Thanks to the force applied during the tightening process, the overlapped threaded parts system act,

by means of elastic deformation on the head of the screw, blocking it and avoiding subsequent

loosening

For the connection of the conductor it is necessary to:

1) Loosen the tightening screw (Pos.4 - Fig. A) until it frictions, making the collar (Pos.5 - Fig. A)

reach its lower position; once this operation is performed, the conductor’s insertion hole results

to be completely open and is ready to house the conductor.

2) Prepare the conductor by stripping one end from its insulation (Fig. B) and according to the

correct insulation stripping length given in the table. introduce it in the terminal block until the

limiting wall is reached. By holding firmly the conductor in one hand, tightening operation must be performed (applying the

prescribed torque values given in the table). Once this operation is performed the conductor is firmly secured.

Thanks to the force applied during the tightening process, the overlapped threaded parts system acts, by means of elastic

deformation on the head of the screw, blocking it and avoiding subsequent loosening