: C

Page 2/16

SUMMARY

1. SAFETY INSTRUCTIONS .................................................................................................................3

2. TECHNICAL DESCRIPTION .............................................................................................................4

2.1. Description ..................................................................................................................................4

2.2. Main characteristics.....................................................................................................................5

2.3. Dimensions..................................................................................................................................5

2.4. Operation.....................................................................................................................................6

2.5. Use..............................................................................................................................................6

2.6. How to rotate the head ................................................................................................................7

2.7. Removing the clamp....................................................................................................................8

2.8. Classification ...............................................................................................................................8

3. MAINTENANCE ................................................................................................................................9

3.1. Periodic check-up of the jaws ......................................................................................................9

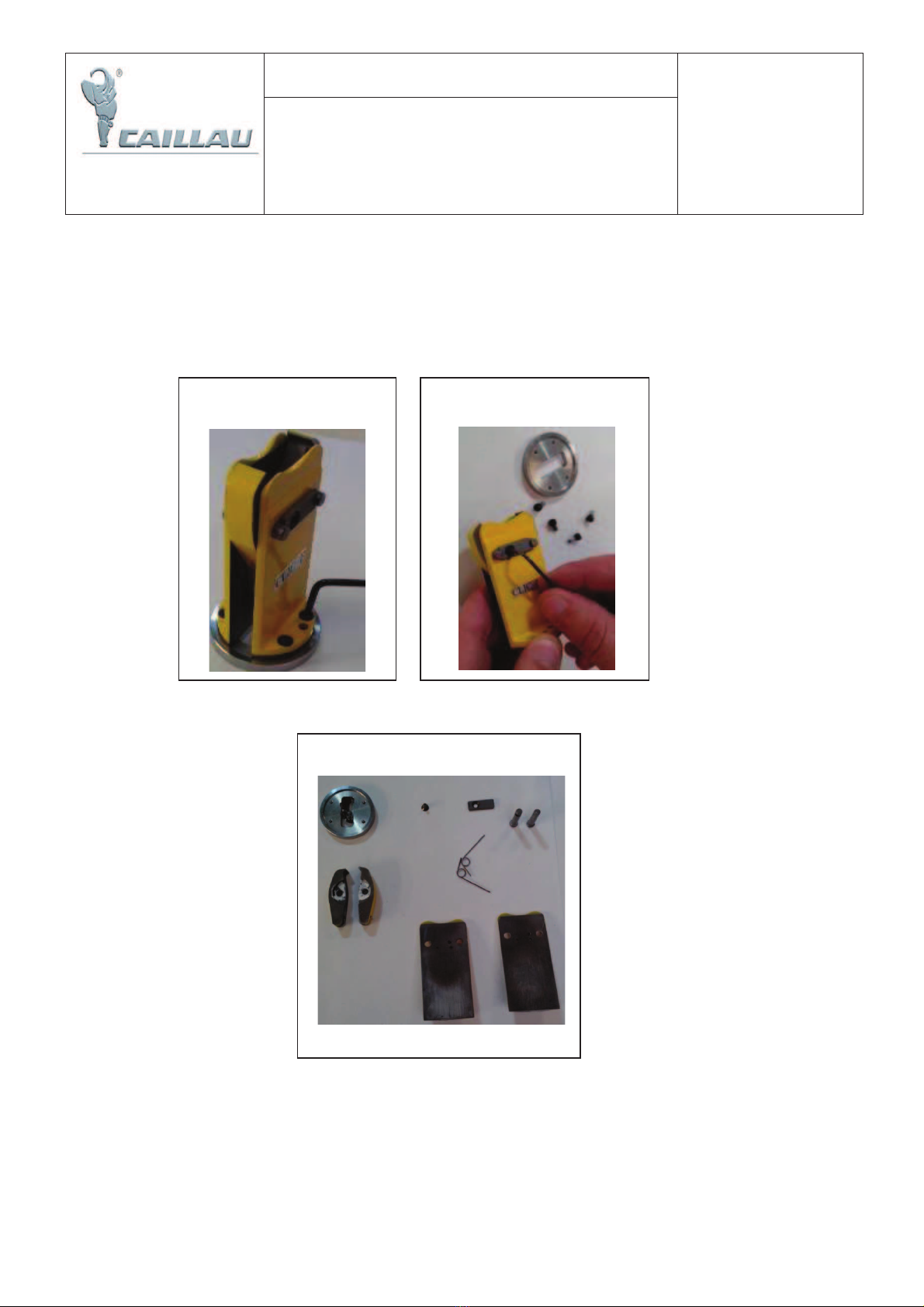

3.2. Replacement of springs, axes and jaws.....................................................................................10

3.2.1. Disassembly .........................................................................................................................10

3.2.2 Assembly ..............................................................................................................................11

3.3. Replacement of the valve block .................................................................................................12

3.4. Spare parts list...........................................................................................................................13

4. PROBLEM RESOLUTION...............................................................................................................14

5. DECLARATION...............................................................................................................................15