7/21/2020

TTU-2900 Hardware & Installation Guide - PULS Wiki

2/29

In order to limit the size and scope of this manual, the following

assumptions have been made about the reader.

1. You are familiar with GPS concepts and terminology

2. You have some experience with installing equipment in vehicles

3. You are familiar with the use of AT Commands

4. You are familiar with the use of terminal programs such as HyperTerminal or PuTTY

1.3 About CalAmp

CalAmp (NASDAQ: CAMP) is a telematics pioneer leading transformation in a global connected economy. Wehelp reinvent businesses and

improve lives around the globe with technology solutions that streamline complex IoT deployments and bring intelligence to the edge. Our

software applications, scalable cloud services, and intelligent devices collect and assess business-critical data from mobile assets, cargo,

companies, cities and people. Wecall this The New How, powering autonomous IoT interaction, facilitating efficient decision making, optimizing

resource utilization, and improving road safety. CalAmp is headquartered in Irvine, California and has been publicly traded since 1983. LoJack is

a wholly owned subsidiary of CalAmp. For more information, visit calamp.com, or LinkedIn, Twitter, YouTube or CalAmp Blog.

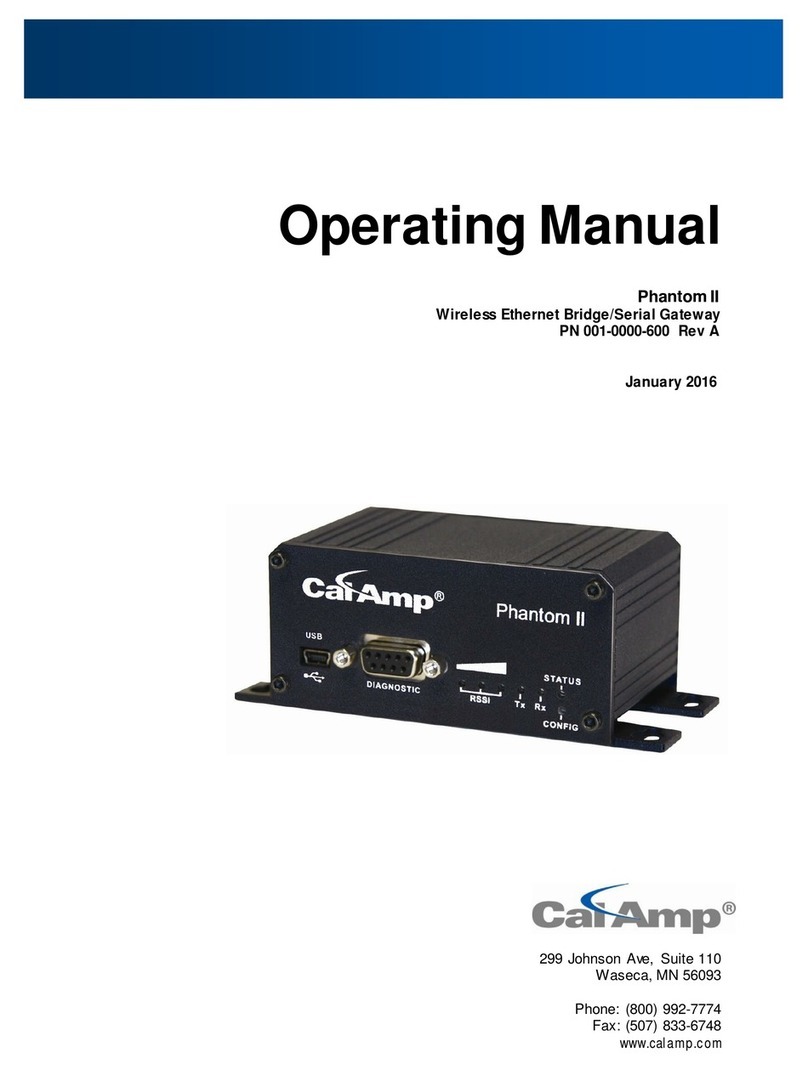

1.4 About the CalAmp Location Messaging Unit - TTU-2900™

The CalAmp Location and Messaging unit-TTU-2900™is a mobile device that resides in private, commercial or government vehicles. The

TTU-2900™is a single box enclosure incorporating a processor, a GPS receiver, a wireless data modem, and a vehicle-rated power supply. The

TTU-2900™also supports inputs and outputs to monitor and react to the vehicular environment and/or driver actions..

The TTU-2900™collects, stores and transmits vehicular and location data over a designated wireless network including LTE and HSPA.

Vehicular and location data are transmitted to a customized software application that has been designed to receive, acknowledge, process, store,

and respond to this data.

Unit location and vehicular information is sent at pre-determined intervals, on demand, or when pre-programmed vehicular conditions are met.

Transmission of data are sent immediately when in wireless network coverage and stored for later transmission when out of the wireless coverage

area. SMS messaging can be used as an alternative or redundant communication backup.

The TTU-2900™is designed to support a variety of custom fleet applications starting with basic automatic vehicle location and including

applications requiring more sophisticated features such as geo-fencing, speed and mileage monitoring, third party security monitoring, dynamic

reporting routines, and an array of exception alerts.

TTU-2900™are sold exclusively to authorized systems integrators, software firms, and service providers who have developed their offering

around the capabilities of the TTU-2900™. Customers are trained by CalAmp to integrate the mobile device with their system and to assist in

support and maintenance of the devices.

Installations of TTU-2900™are performed by CalAmp customers or contracted installers. Typical installations include hook-up to power,

ignition, and ground. TTU-2900™s and the corresponding wiring are almost always hidden from view and general access. Placement of the units

is usually under dashboards, in trunks or in compartments.

2System Overview

2.1 Overview

The entire purpose behind a fleet management system is to be able to remotely contact a vehicle, determine its location or status, and do

something meaningful with that information. This could include displaying the vehicle location on a map, performing an address look-up,

providing real-time driving directions, updating the vehicles ETA, monitoring vehicle and driver status or dispatching the vehicle to its next pick

up.

These functions, of course, are completely dependent on the capabilities of the vehicle management application. The role of the CalAmp LMU-

3640™is to deliver the location information when and where it is needed.

A typical fleet management system based on a CalAmp device includes the following components:

A wireless data network

An TTU-2900™

Host Device (GPS NMEA only)

An LM Direct™communications server

Backend mapping and reporting software which typically includes mapping and fleet reporting functions

PULS™

LMU Manager™