7.

Instructions continued onpage 8. >>>>

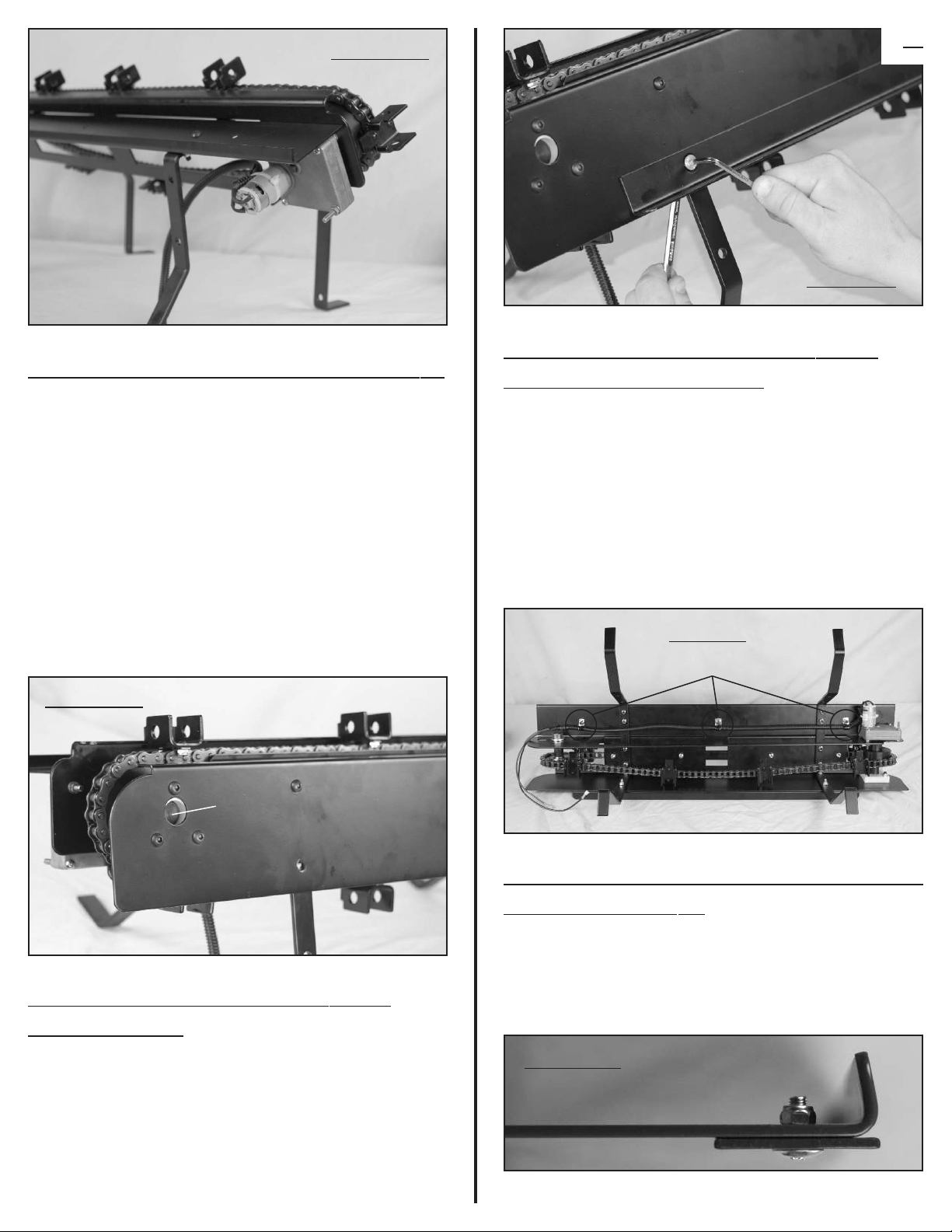

PHOTO P

PHOTO Q

STEP 11: Attach the Self-Adhesive

Target Spots to the Targets

STEP 12: Battery Charging and

SystemTest

Important: Do not overcharge the battery.

Nevercharge the battery while connected to the

Shootin’ Gallery. Charge ina well-ventilated area.

Use the provided Charger (1001480) to charge the

Battery (1000545). Connect the alligator clips to the

Battery before plugging the Charger into the wall. Make

sure the clips are connected tightly and securely to the

terminals on the Battery. The light on the Battery

charger will illuminate RED while charging and GREEN

when fully charged. Important: Do not overcharge

the Battery. To avoid damaging the Battery, remove

the Battery immediately when the light turns GREEN.

The ChargerDOES NOT turn itself off.

Avoid fully discharging the Battery. Deep discharging

can damage the Battery. When you notice the Shootin’

Gallery slowing down because the Battery charge is

low, stop and recharge the Battery. It may take several

hours to charge the Battery. Monitor indicator light.

WARNING: Keep hands and clothing clear

of chain,sprocket, and othermoving parts.

Make sure the switch is turned OFF. Carefully

connect the Red Wire to the Red battery ter-

minal and the black wire to the black battery terminal.

Place the Battery in the Battery Box and replace the

access panel and secure with the wing bolt. Make sure

wires are not pinched when replacing the access panel.

WARNING: Keep hands and clothing clear

of chain,sprocket, and othermoving parts.

Turn power switch ON. Targets should move from left

to right as you face the front of the Shootin’ Gallery.

(If not, check Battery connections.)

Carefully use a small stick such as a ruler or yardstick

to knock over a couple of the targets. As the fallen targets

rotate around the chain, they should reset automatically.

Turn switch off.

CONGRATULATIONS: Youare now ready to

set up your Shootin’ Gallery foruse. Read

instructions carefully.

SETTING UP AND USING YOUR

SHOOTIN’ GALLERY

1. Place the Shootin’ Gallery on level, soft ground

where there is a good backstop, such as a hill or berm

of soft earth. A .22 caliber bullet can travel as much as

a mile before losing energy. Be sure that if you miss

the target, your round will be stopped safely. Do not

place the shootin’ gallery on an elevated surface. The

Shootin’ Gallery must be at the same level as the

shooter’s feet. Always shoot from a position directly in

front of the Shootin’ Gallery. Shooting from an angle

could cause ricochet or prevent targets from falling.

2. Inspect the Shootin’ Gallery for damage and loose

or missing parts before each use. Tighten any loose

bolts or screws (impact from shooting can loosen

them). DO NOT USE IF PRODUCT IS DAMAGED,

MISSING PARTS, OR IF TARGETS ARE DEFORMED.

Replacement parts are available from Battenfeld

Technologies, Inc. www.battenfeldtechnologies.com

3. Inspect wires for wear and make sure they are

properly secured.

4. WARNING: Keep hands and clothing clearof

chain,sprocket, and othermoving parts. Make

sure power switch is OFF and connect the fully

charged battery. Note: You may need to charge

battery before use. Turn power switch ON. Targets

should move from left to right as you face the front