SAT102 heat nterface un t

4

Installat on

The SATK ser es HIUs are des gned for nstallat on n a sheltered

domest c env ronment (or s m lar), therefore cannot be nstalled

or used outdoors, .e. n areas d rectly exposed to atmospher c

agents. Outdoor nstallat on may cause malfunct on ng and

hazards.

If the dev ce s enclosed ns de or between cab nets, suffic ent

space must be prov ded for rout ne ma ntenance procedures. It s

recommended that electr cal dev ces are NOT placed underneath

the HIU, as they may be damaged n the event of leakage from

any hydraul c component of connect on.

If th s adv ce s not heeded, the manufacturer cannot be held

respons ble for any result ng damage.

In the event of a malfunct on, fault or ncorrect operat on, the

dev ce should be deact vated; contact a qual fied techn c an for

ass stance.

NOTE for all models:

If a non-return valve s fitted nto the domest c hot water (DHW)

cold water nlet, prov s on MUST be made to accommodate the

expans on of the DHW conta ned w th n the HIU.

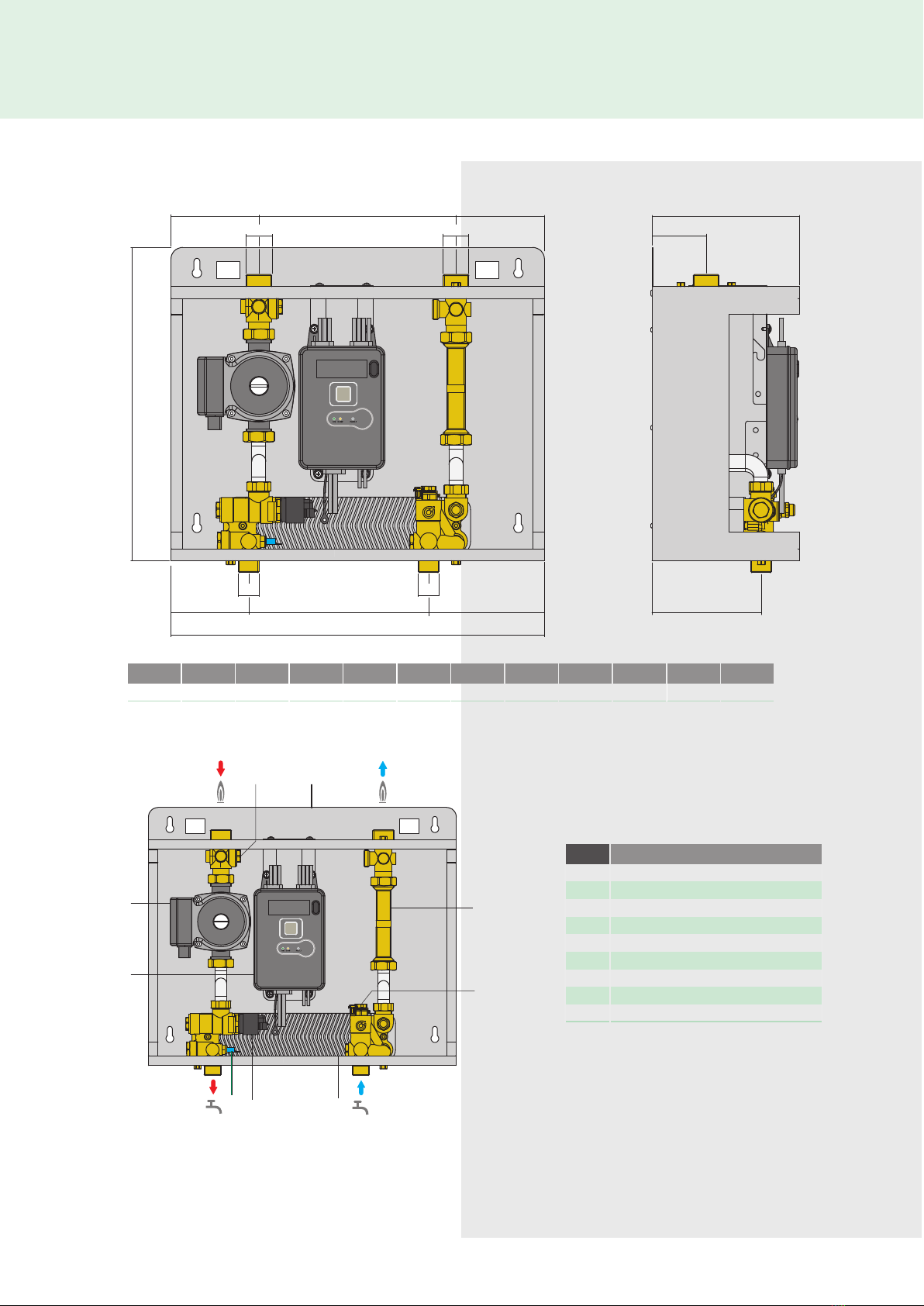

Preparat on

After establ sh ng the pos t on where the HIU w ll be nstalled,

perform the follow ng operat ons:

•Mark the holes requ red for secur ng the HIU to the wall.

•Mark the pos t on of the water p pe connect ons.

Check the measurements aga n before nstall ng p pework and

electr cal cables.

Hydraul c connect ons:

1connect on to the p pework from the central sed bo ler plant

2domest c water c rcu t connect on

Electr cal:

1electr c supply l ne 230 V (ac) – 50 Hz

2t me clock/thermostat l ne (potent al-free)

3central sed bus l ne for heat meter data transm ss on ( f

requ red)

4central sed electr c supply l ne for heat meter ( f requ red)

The whole system should be thoroughly flushed to remove any

debr s that may be n the supply p pework to the HIU and to the

domest c hot water p pework n the apartment before connect ng

the HIU.

F x the HIU to the wall

N.B.: the wall anchors (not suppl ed) can only guarantee effect ve

support f nserted correctly ( n accordance w th good techn cal

pract ce) nto walls bu lt us ng sol d or sem -sol d br cks. If

work ng w th walls bu lt us ng perforated br cks or blocks, mob le

d v d ng panels or any masonry walls other than those nd cated,

a prel m nary stat c test must be carr ed out on the support

system.

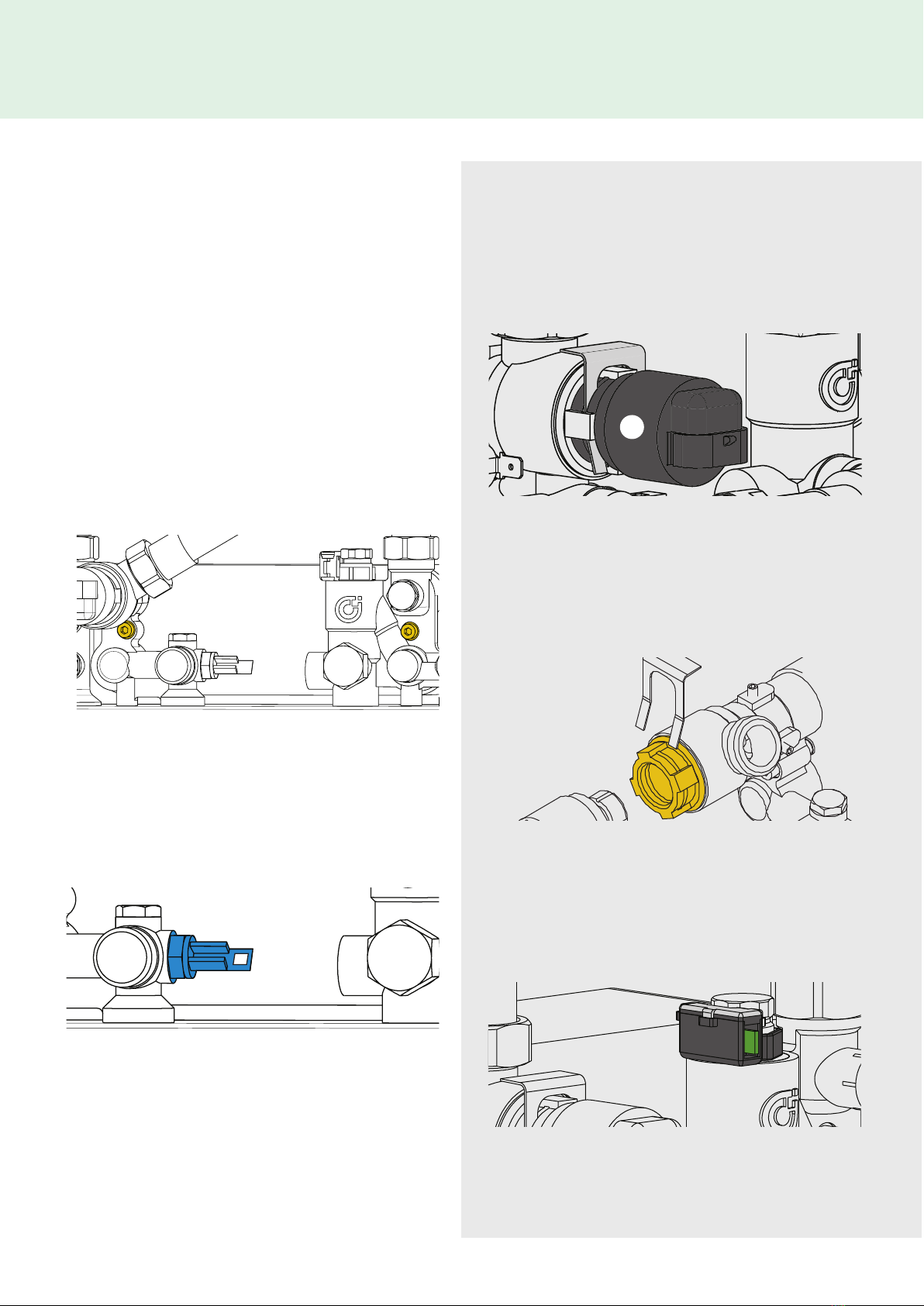

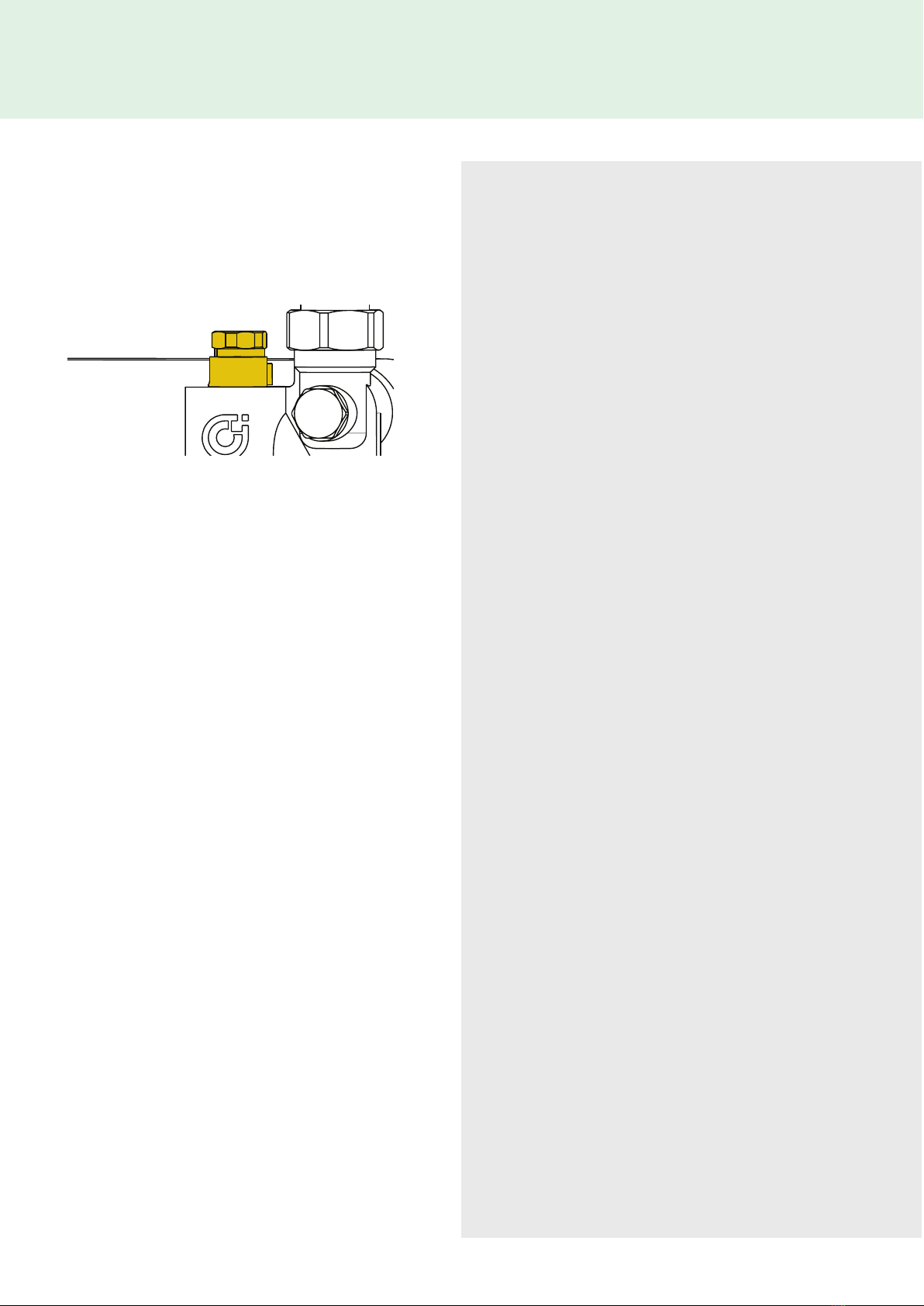

Isolat on Valves

Depend ng on the spec ficat on ordered, the HIU may be

suppl ed w th a var ety of solat on valves. We recommend that

all connect ons are fitted w th solat on valves to allow any

ma ntenance work to be carr ed out.

We would also recommend that the pr mary system ncludes a

flush ng bypass, w th an solat on valve, mmed ately upstream

of the HIU, to allow the pr mary system to be flushed pr or to

the first operat on of the un t.

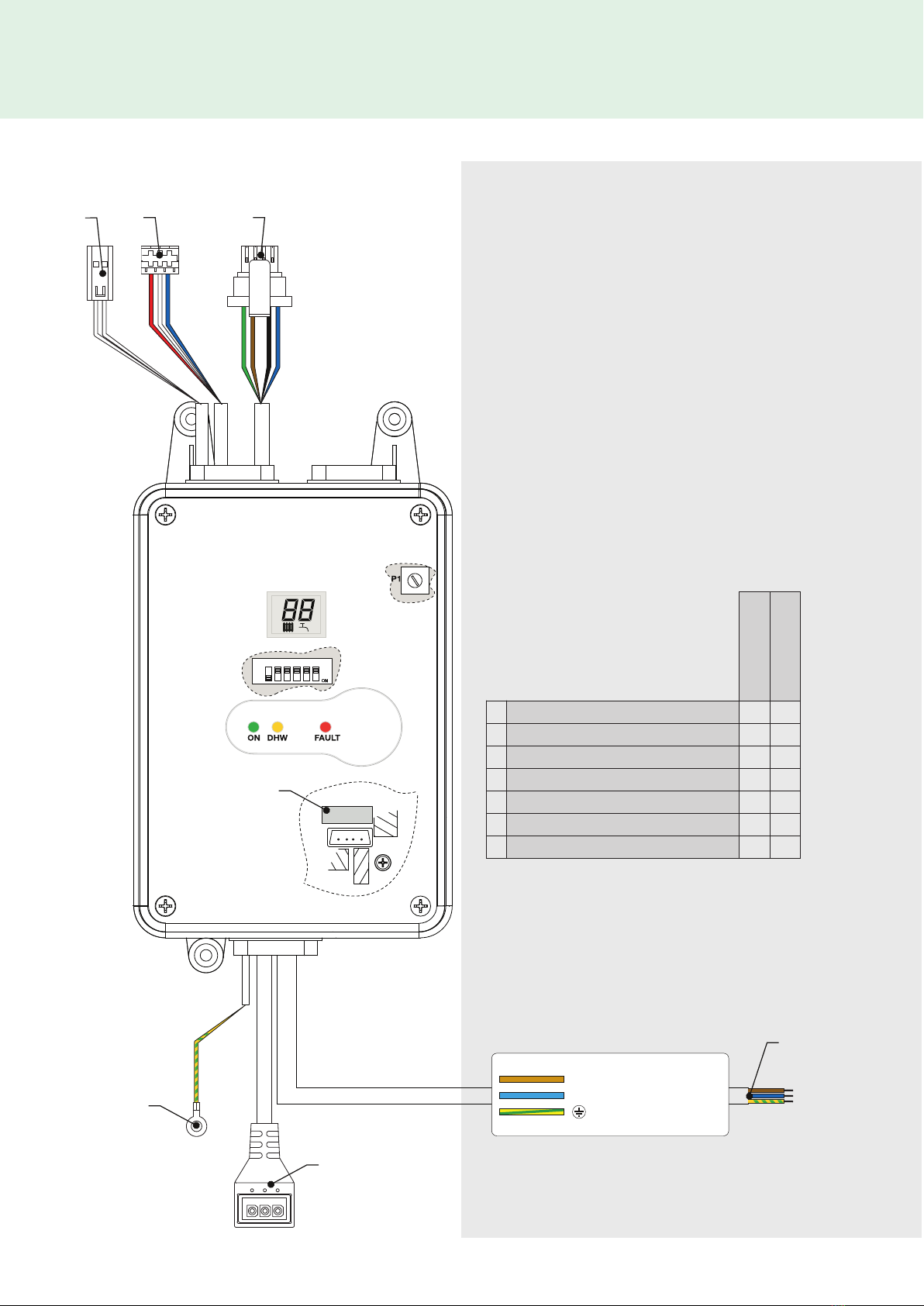

Electr cal Connect ons

Make sure that the electr cal system can w thstand the

max mum power consumpt on of the appl ance, w th part cular

emphas s on the cross-sect on of the cables.

If n doubt, contact a qual fied techn c an to thoroughly check

the electr cal system.

Electr cal safety of the appl ance s only ach eved when t s

correctly connected to an effect ve earth ng system,

constructed as spec fied n current safety regulat ons. Th s s a

compulsory safety requ rement.

Connect on to the ma n supply

The dev ce s suppl ed w th an electr c supply cable - plug not

suppl ed.

The dev ce should be electr cally connected to a 230 V (ac)

s ngle phase + earth ma ns supply us ng the three-w re cable

marked w th the label as spec fied below, observ ng the LIVE (L)

- NEUTRAL (N) polar t es and the earth connect on.

Th s l ne must be connected to a c rcu t breaker dev ce.

F ll ng the pr mary heat ng system

Open the solat on valves on the connect ons to the central sed

bo ler plant to fill and pressur se the system to the des gn

pressure.

Once completed, vent the system and check the system

pressure aga n, repeat the fill ng process f necessary.

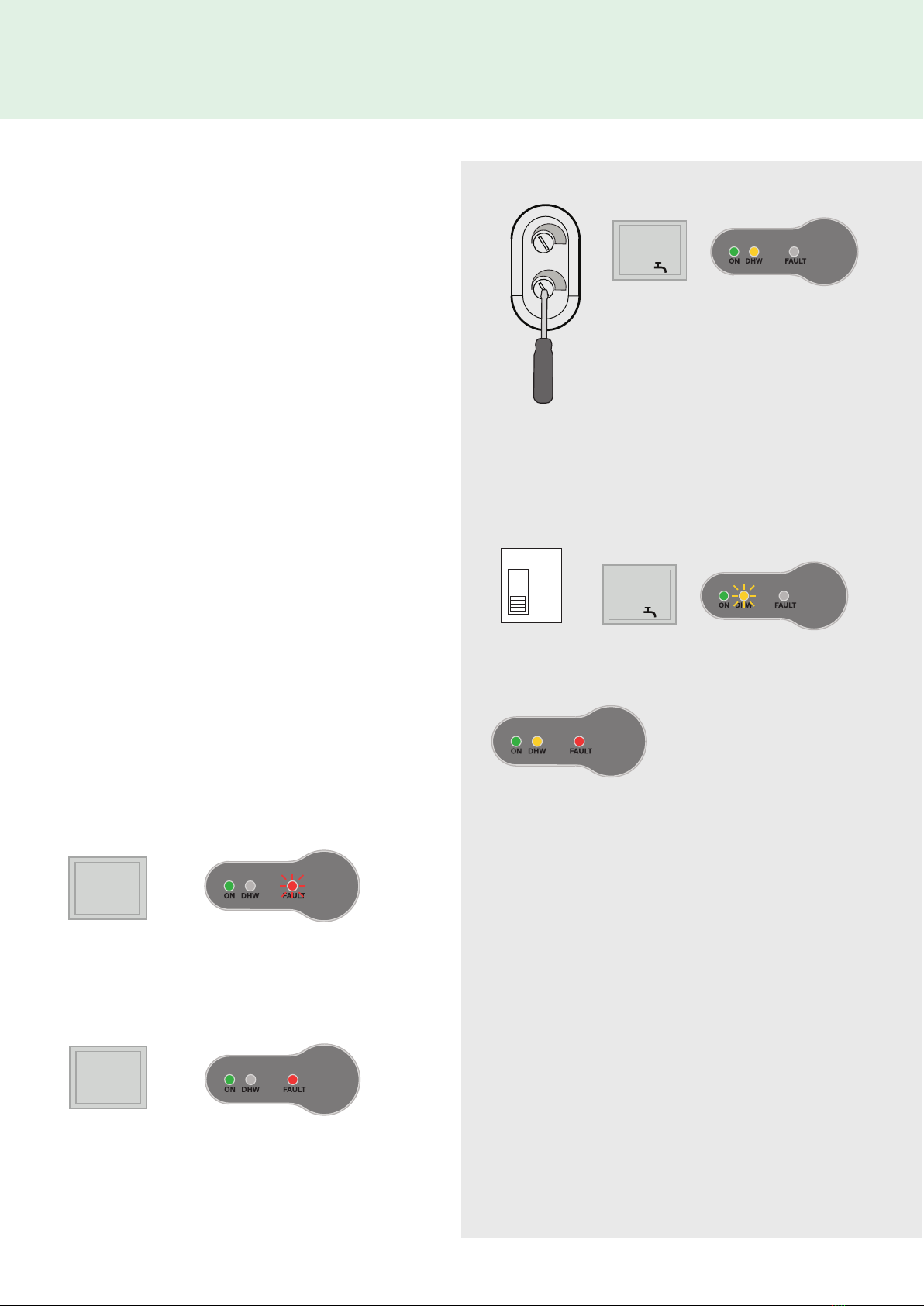

System start-up

Before us ng the HIU, v sually check that the hydraul c

connect ons are water t ght and the electr cal w r ng.

After complet ng the checks, sw tch on the electr c ty supply to

the HIU and check for the presence of any error s gnals.

If error s gnals are nd cated, el m nate the fault us ng the

procedure descr bed on page 6.

For HIUs w th an ntegral pump the follow ng appl es;

Once the HIU s hydraul cally filled (pr mary and

secondary), the HIU should be left permanently connected

to the ma ns supply and sw tched on. Th s allows the un t

to operate ts pump ant -clog protocol.