SATK20 & SATK30

4

Technical Specification - SATK20

Medium: Water

Max. percentage of glycol 30%

Max. temperature: 85˚C

Max. working pressure: Primary circuit: 10 bar

Domestic hot water: 10 bar

Nom. DHW heat exchanger net output: 50 kW

Max. recommended primary circuit flow rate: 1.2 m³/h

DHW circuit max. flow rate: 18 l/m (0.3 l/s)

Min.flow rate to activate domestic flow sensor: 2.7 l/m ±0.3

Max. differential pressure on domestic

water modulating valve: ∆p 0.9 bar

Max. differential pressure on mixing valve: ∆p 0.9 bar

Power supply: 230 V (ac)±10% 50 Hz

Power consumption: 105 W (SATK 20203)

Protection class: IP 40

Pump: UPS 15/60

Pump bypass setting: 0.45 bar

Actuator: stepper 24 V

Probes: NTC 10 kΩ

Safety thermostat: 55˚C ±3

Technical Specification - SATK30

Medium: Water

Max. percentage of glycol 30%

Max. temperature: 85˚C

Max. working pressure: Primary circuit: 16 bar

Secondary circuit: 3 bar

Domestic hot water: 10 bar

Nom. heating exchanger net output: 15 kW

Nom. DHW heat exchanger net output:

SATK30103: 50 kW

SATK30105: 75 kW

Max. recommended primary circuit flow rate: 1.2 m³/h

DHW circuit max. flow rate: 18 l/m (0.3 l/s)

Min.flow rate to activate domestic flow sensor: 2.7 l/m ±0.3

Max. differential pressure on domestic

water modulating valve: ∆p 0.9 bar

Power supply: 230 V (ac)±10% 50 Hz

Power consumption: 105 W

Protection class: IP 40

Pump: UPS 15/60

Pump bypass setting: 0.45 bar

Actuator: stepper 24 V

Probes: NTC 10 kΩ

Safety relief valve setting: 3 bar

Safety thermostat: 55˚C ±3

Expansion vessel: 7.5 litre

Pressure switch: opening 0.4 bar - closing 0.8 bar

Material

Components: brass BS EN 12165 CW617N

Pipes: stainless steel

Frame: RAL 9010 sprayed steel

Protective shell cover: PPE

Exchanger: brazed stainless steel

Installation

The SATK series HIUs are designed for installation in a sheltered

domestic environment (or similar), therefore cannot be

installed or used outdoors, i.e. in areas directly exposed to

atmospheric agents. Outdoor installation may cause

malfunctioning and hazards.

If the device is enclosed inside or between cabinets, sufficient

space must be provided for routine maintenance procedures. It

is recommended that electrical devices are NOT placed

underneath the HIU, as they may be damaged in the event of

discharge from the safety valve, if it is not connected to a

discharge tundish (SATK30103 and SATK30105), or in the event

of leaks occurring at the hydraulic fittings.

If this advice is not heeded, the manufacturer cannot be held

responsible for any resulting damage.

In the event of a malfunction, fault or incorrect operation, the

device should be deactivated; contact a qualified technician for

assistance.

NOTE for all models:

If a non-return valve is fitted into the domestic hot water

(DHW) cold water inlet, provision MUST be made to

accommodate the expansion of the DHW contained within the

HIU.

Preparation

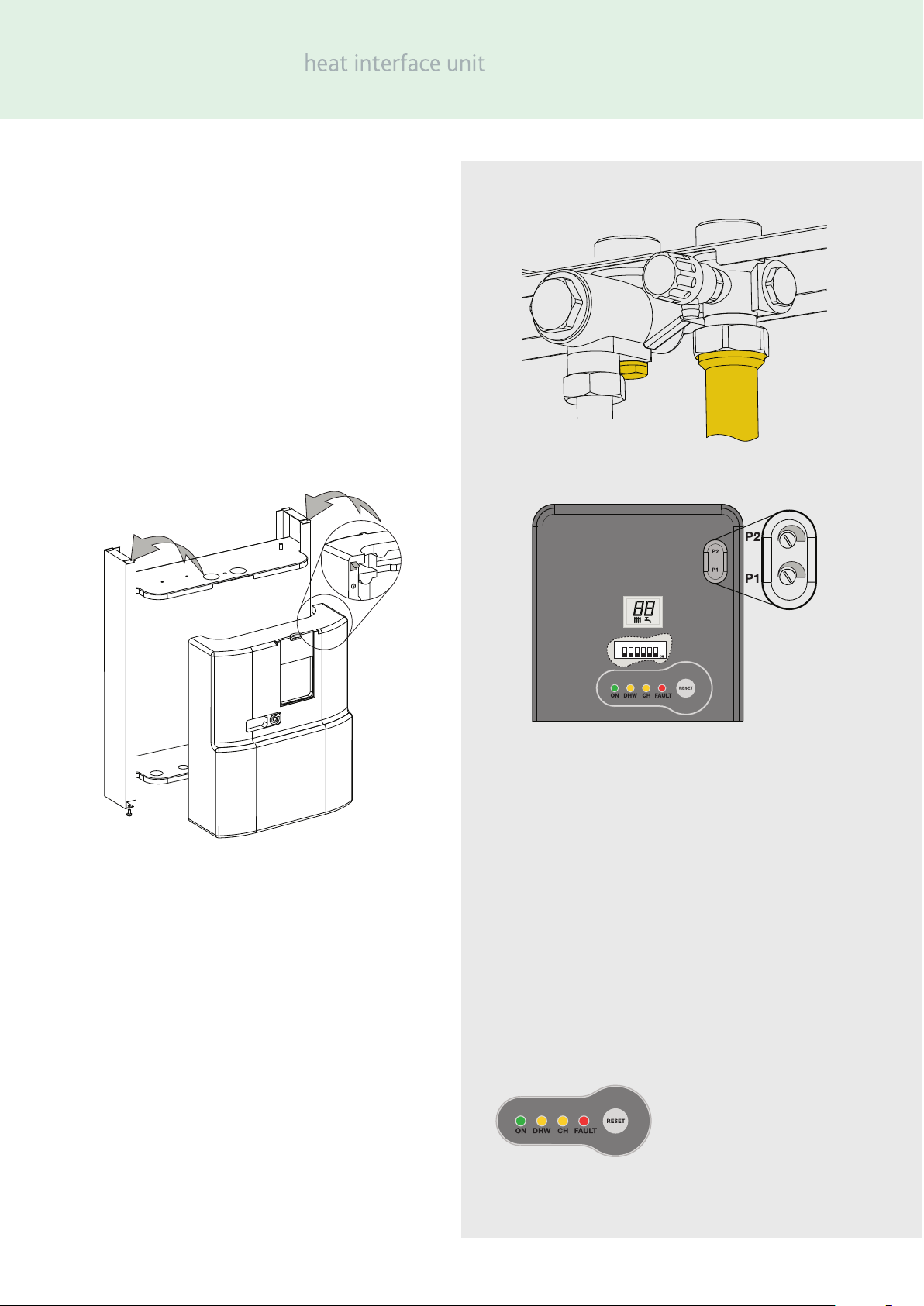

After establishing the position where the HIU will be installed,

perform the following operations:

•Mark the holes required for securing the HIU to the wall.

•Mark the position of the water pipe connections.

Check the measurements again before installing pipework and

electrical cables.

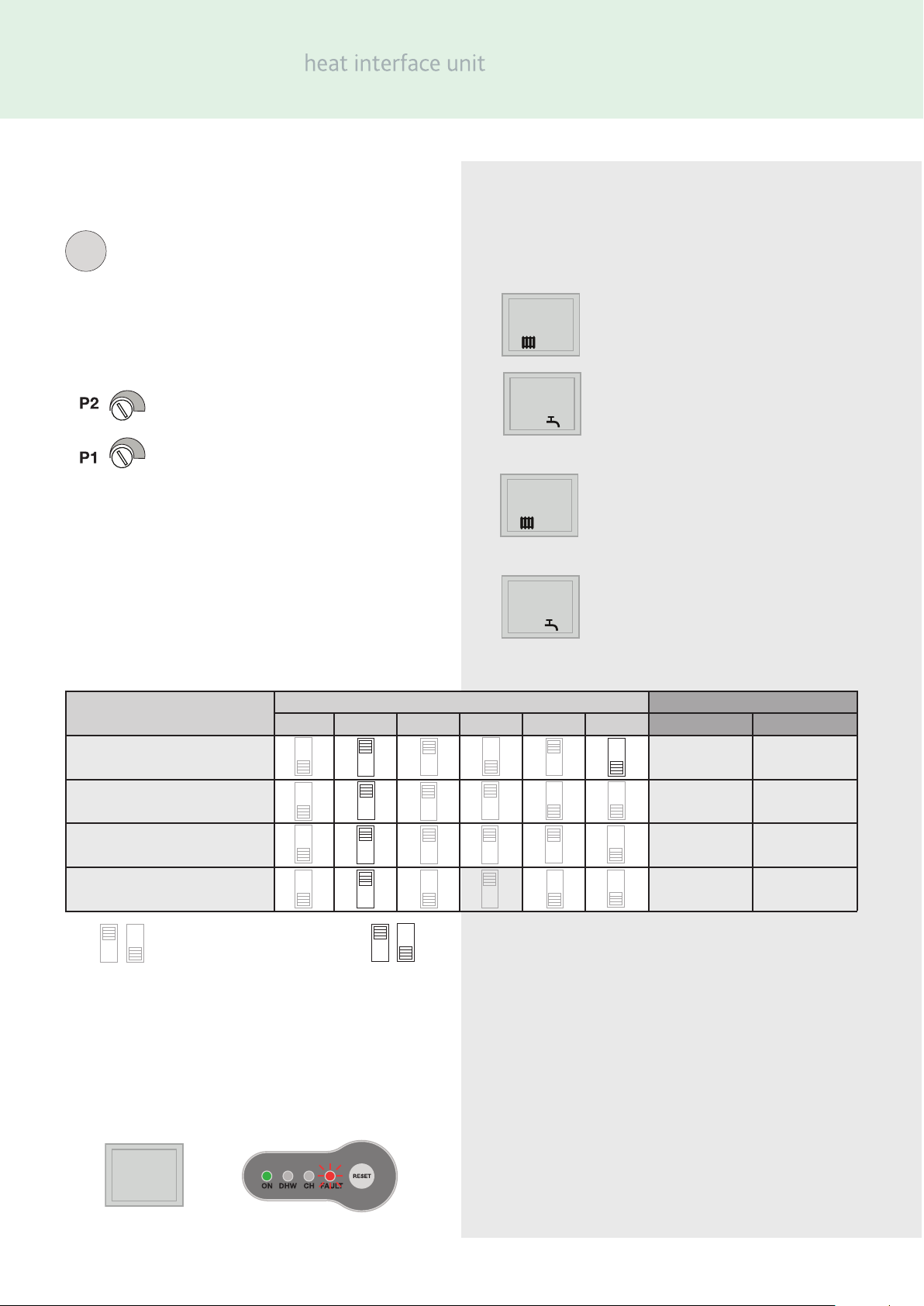

Hydraulic connections:

1connection to the pipework from the centralised boiler

plant

2heating circuit connection

3domestic water circuit connection

4discharge from safety relief valve

Electrical:

1electric supply line 230 V (ac) – 50 Hz

2time clock/thermostat line (potential-free)

3centralised bus line for heat meter data transmission (if

required)

4centralised electric supply line for heat meter (if required)