Commissioning

Filling the centr l he ting system

Open the shut-off valves (not supplied) on the connections to the

centralised line and, in the central heating system, proceed with

filling the system to the design pressure. Once these procedures

are complete, vent the system and check its pressure again (repeat

the filling process if necessary).

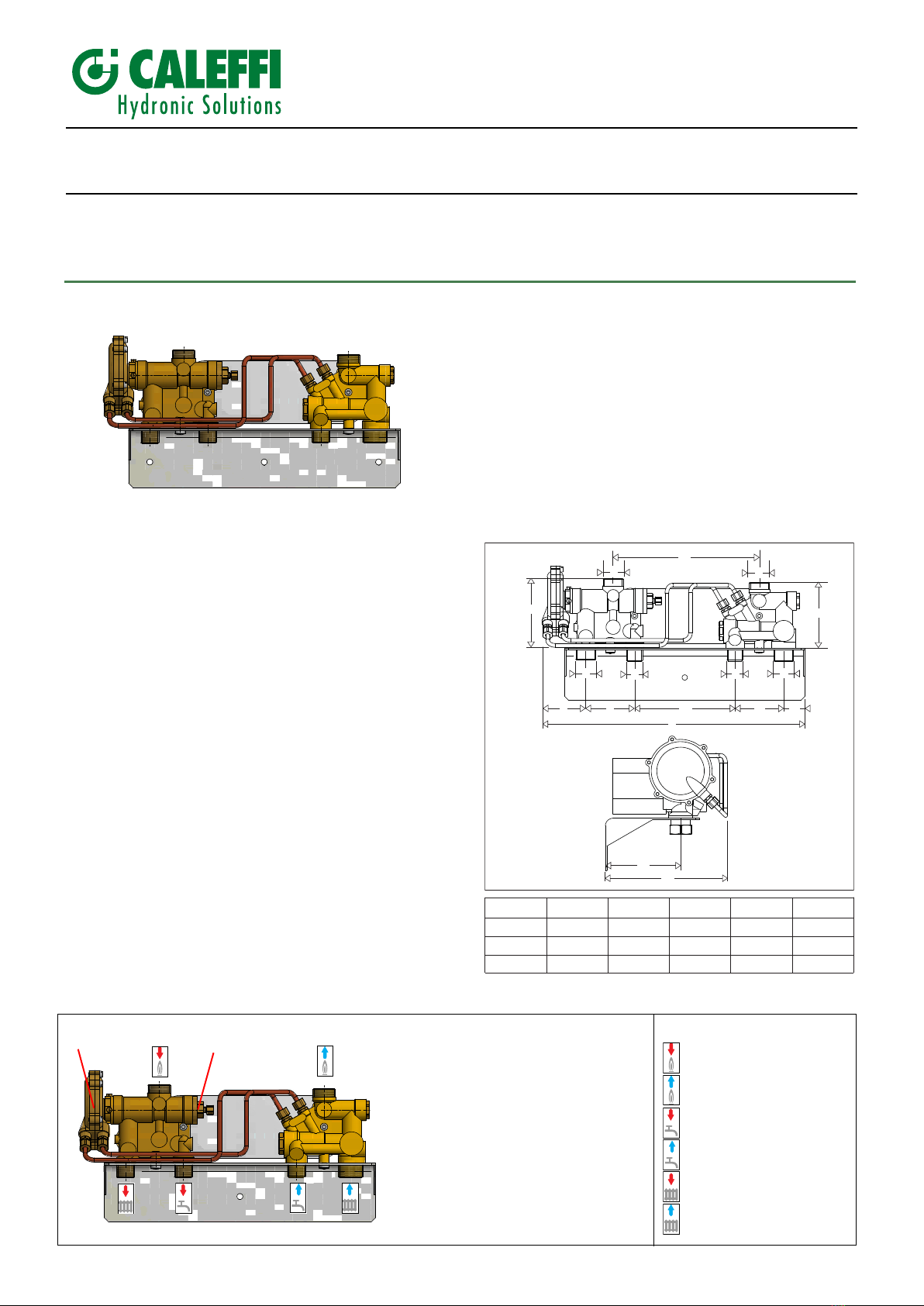

Exch nger prehe ting function

In order to keep pipe sections between the risers and the

apartment heating system from cooling and consequently to speed

up the response to demands for DHW production, SATK12313 HIU

is equipped with a manual by-pass that makes it possible to

maintain a minimum flow of water circulating through the heat

exchanger primary circuit.

To activate the preheating function turn knob (A).

M inten nce

All maintenance procedures should be carried out by an authorised

technician.

Regular maintenance guarantees better efficiency and helps to

save energy.

Before carrying out any maintenance, repairs or replacement of

parts, proceed as follows:

- Close the shut-off valves

- Empty the HIU.

He t exch nger repl cement

- Remove the heat exchanger by loosening the 2 hex socket fixing

screws (B)

- Replace the heat exchanger and the O-rings.

- Tighten the two fixing screws to a maximum torque of 3 N·m (B).

2

Inst ll tion

The SATK series HIU is designed for installation in a sheltered

domestic environment (or similar), therefore it cannot be installed or

used outdoors, i.e. in areas directly exposed to the elements.

Outdoor installation may cause malfunctioning and hazards.

If the device is enclosed inside or between cabinets, sufficient space

must be provided for routine maintenance procedures. It is advisable

to avoid positioning electrical devices under the HIU as they may be

damaged in the event of leaks from hydraulic fittings. If this advice is

not heeded, the manufacturer cannot be held responsible for any

resulting damage. In the event of a malfunction, fault or incorrect

operation, the device should be deactivated; contact a qualified

technician for assistance.

Prep r tion

After having established the point of installation of the device,

perform the following operations:

• ark the holes required to secure the HIU to the wall

• ark the position of the hydraulic connections

Check the measurements again and begin laying the following lines:

1. connection to the centralised line

2. heating circuit connection

3. domestic water circuit connection.

Before installation, it is recommended to carry out accurate flushing

of all the pipes of the system in order to remove any residue or

impurities that could endanger correct operation of the HIU. Fix the

HIU to the wall.

N.B.: the wall anchors can only guarantee effective support if

inserted correctly (in accordance with good technical practice) into

walls made of solid or semi-solid bricks. If working with walls built

using perforated bricks or blocks, mobile dividing panels or any

masonry walls other than those indicated, a preliminary static test

must be carried out on the support system.

Hydr ulic connections

Hydraulic connections to the centralised line must be made using

manual shut-off valves which allow any necessary maintenance work

to be carried out without having to empty the centralised system.

It is advisable to install manual shut-off valves also on the lower

terminals for connection to the apartment heating system.

ake sure all connections are perfectly watertight.

WARNINGS

These instructions must be read and understood before installing and maintaining the device.

CAUTION! FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN A SAFETY HAZARD!

CAUTION!

THE PRODUCT SUPPLIED WITH THIS INSTRUCTION SHEET WILL BE DESIGNATED “DEVICE” HEREINAFTER

1 The device must be installed, commissioned and maintained by qualified technical personnel in accordance with national regulations and/or applicable local bylaws.

2 If the device is not installed, commissioned and maintained correctly in accordance with the instructions provided in this manual, it may not work properly and may

endanger the user.

3 Clean the pipes of any particles, rust, incrustations, limescale, welding slag and any other contaminants. The hydraulic circuit must be clean.

4 ake sure all connection fittings are watertight.

5 When connecting water pipes make sure the threaded connections are not mechanically overstressed. Over time this may result in breakage, causing water damage

and/or personal injury.

6 Water temperatures higher than 50°C can cause severe burns. When installing, commissioning and servicing the device, take the necessary precautions so that

these temperatures do not constitute a threat for personal safety.

7 In the case of particularly hard or impure water, there must be suitable provision for filtering and treating the water before it enters the device, in accordance with

statutory legislation. Otherwise the device may be damaged and will not work properly.

8 Any use of the device other than its intended one is prohibited.

9 Any combination of the device with other system components must be made taking the operational characteristics of both units into consideration. An incorrect

combination could impair operation of the device and/or system.

LEAVE THIS ANUAL AS A REFERENCE GUIDE FOR THE USER. DISPOSE OF THE PRODUCT IN CO PLIANCE WITH CURRENT LEGISLATION

THE ANUFACTURER RESERVES THE RIGHT TO CEASE PRODUCTION AT ANY TI E AND TO AKE ANY CHANGES DEE ED USEFUL OR NECESSARY

WITHOUT THE OBLIGATION OF PRIOR NOTICE.

SAFETY INSTRUCTIONS

A

B