SATK22

2

General Informat on

•Please leave the manual as a reference gu de for the user.

•D spose of any packag ng n an appropr ate manner, most

of wh ch can be recycled.

•In th s Installat on, Operat on and Ma ntenance gu de we

have endeavoured to make the nformat on as accurate as

poss ble.

We cannot accept any respons b l ty should t be found

that n any respect the nformat on s naccurate or

ncomplete or becomes so as a result of further

developments or changes to the products.

Key to SymbolsSafety Instruct ons

7In the case of part cularly hard or mpure water, there must

be su table prov s on for filter ng and treat ng the water

before t enters the dev ce, n accordance w th current

leg slat on. Fa lure to do so may result n the HIU becom ng

damaged or work ng ncorrectly.

8Any use of the HIU other than t’s ntended use s

proh b ted.

9Any coupl ng of the dev ce w th other system components

must be made wh le tak ng the operat onal character st cs

of both un ts nto cons derat on.

10 An ncorrect coupl ng could comprom se the operat on of

the dev ce and/or system.

NOTE: R sk of electr c shock. L ve parts. Shut off the electr c

supply before open ng the HIU cover.

1Dur ng nstallat on and ma ntenance operat ons, always

avo d d rect contact w th l ve or potent ally hazardous parts.

2The dev ce must not be exposed to dr pp ng water or

hum d ty, d rect sunl ght, the elements, heat sources or h gh

ntens ty electromagnet c fields.

Th s dev ce cannot be used n areas at r sk of explos on or

fire.

3The dev ce must be connected to an ndependent b polar

sw tch. If work has to be done on the dev ce, sw tch off the

electr c supply first. Do not use dev ces w th automat c or

t me reset, or wh ch may be reset acc dentally.

4Use su table automat c protect on dev ces n compl ance

w th current leg slat on.

5The dev ce must always be earthed before t s connected to

the electr c supply. If the dev ce has to be removed, always

d sconnect the earth connect on after d sconnect ng the

electr c supply. Check that the earth connect on has been

made to the h ghest of standards under current leg slat on.

6Electr cal nstallat on must only be carr ed out by a qual fied

techn c an, n accordance w th current requ rements.

7The HIU does not conta n asbestos or mercury.

8The HIU should only be used by an author sed adult.

NOTES:

1Install water hammer arresters to compensate for any

overpressure n the domest c water c rcu t.

2In the presence of hot water re-c rculat on or f a check valve

s fitted nto the domest c cold water nlet, su table dev ces

must be used to accommodate the expans on of the

med um conta ned w th n the system and the heat nterface

un t.

3All hydraul c connect ons must be v sually checked wh le

pressur s ng the system. V brat on dur ng transport may

cause the connect ons to become loose. If a fitt ng needs to

be t ghtened apply an appropr ate t ghten ng torque,

otherw se the components may become damaged.

Mater al

Components: brass BS EN 12165 CW617N

P pes: sta nless steel

Frame: RAL 9010 sprayed steel

Exchanger: brazed sta nless steel

Insulat on

Protect ve shell cover: EPP

Dens ty: 45 kg/m3

Work ng temperature range: 3 to 90˚C

Thermal conduct v ty: 0.04 W/mK

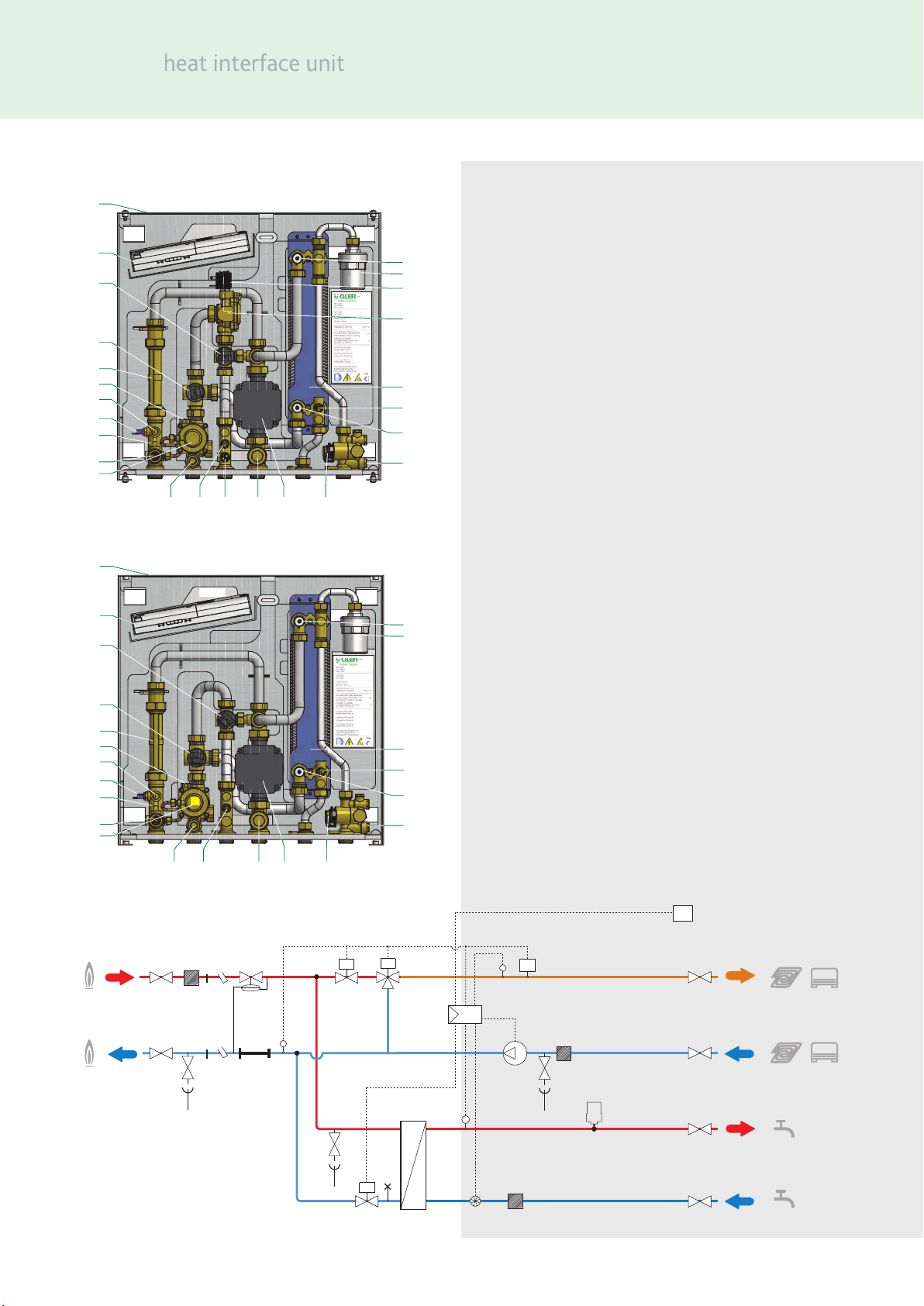

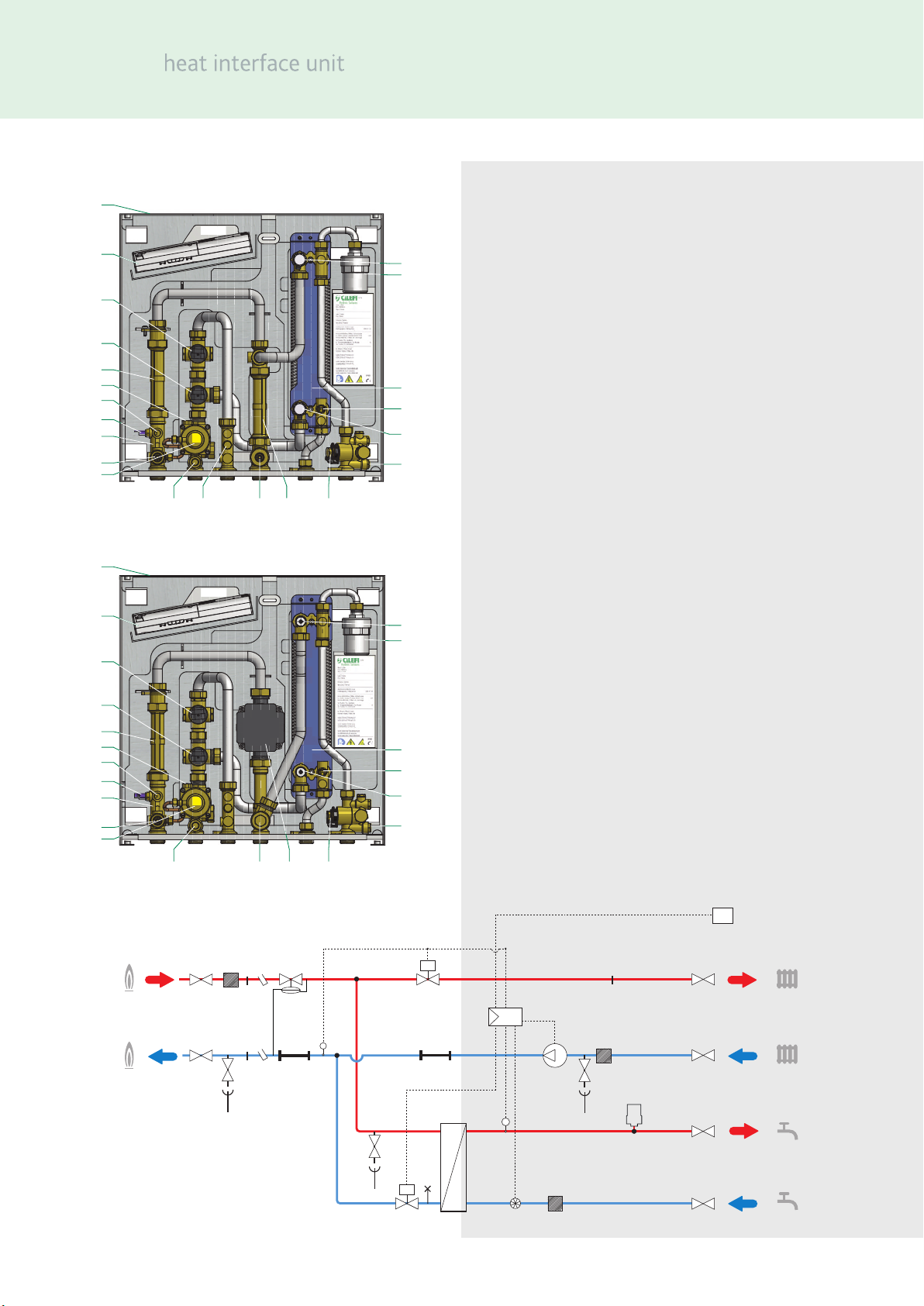

Hightemperaturecircuit flow

Hightemperaturecircuitreturn

Mediumtemperaturecircuit flow

Mediumtemperaturecircuitreturn

Lowtemperaturecircuit flow

Lowtemperaturecircuitreturn

Domestic hotwateroutlet

Domestic cold water inlet

Primary circuit flow

Primary circuit return