MAINTENANCE

Our customer service representatives are available for application assistance, calibration, repair, and

solutions to specific problems. Contact our Service Department before returning any equipment. In

many cases, problems can be solved over the telephone. If the sensor is not performing as it should,

try to match the symptom below to the problem. If the table does not help, call Calex for further advice.

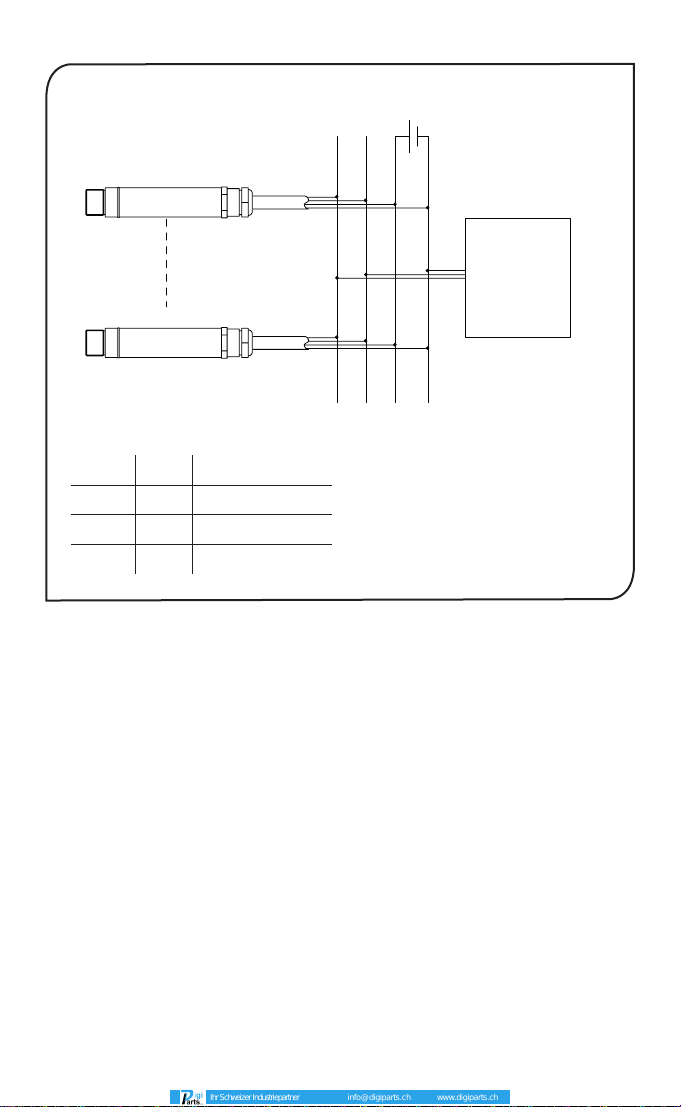

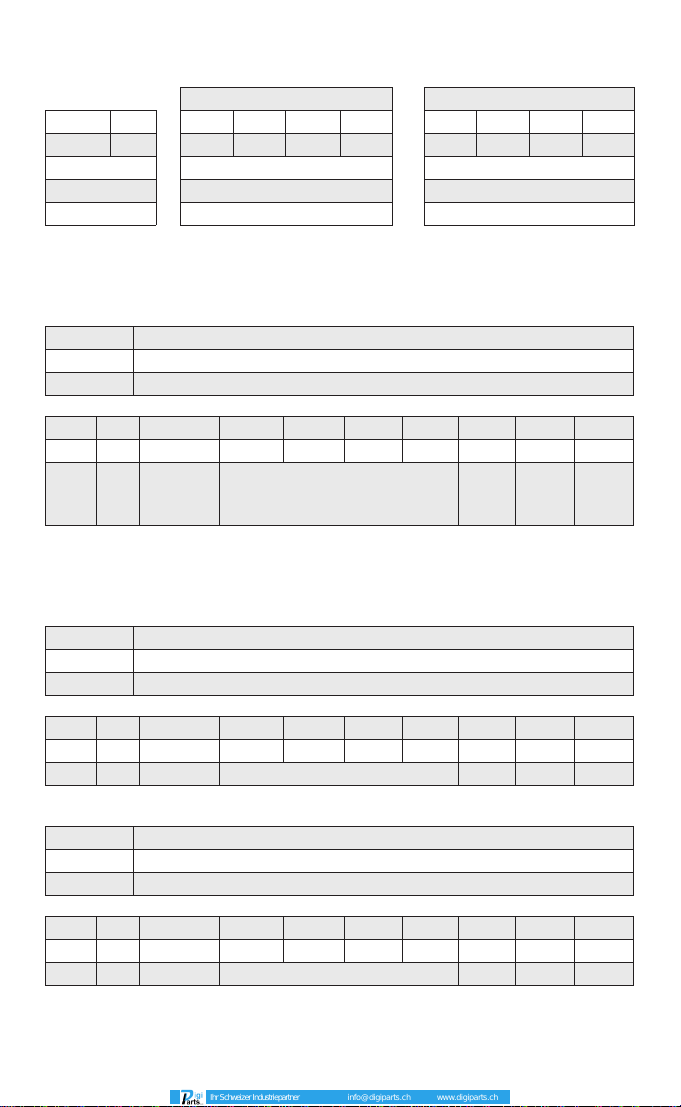

Troubleshooting

Symptom Probable Cause Solution

No output No power to sensor Check power supply

Erroneous temperature Incorrect wire connection Check wire colour codes

Erroneous temperature Faulty sensor cable Verify cable continuity

Erroneous temperature Field of view obstruction Remove obstruction

LENS CLEANING

Keep the lens clean at all times. Any foreign matter on the lens would affect measurement accuracy.

Blow off loose particles (if not using the air purge accessory) with an air ‘puffer’.

GUARANTEE

Calex guarantees each instrument it manufactures to be free from defect in material and workmanship

under normal use and service for the period of one year from the date of purchase. This guarantee

extends only to the original buyer according to Calex terms and conditions of Sale.

OPERATION

Once the sensor is in position and the appropriate power, air, water, and cable connections are secure,

the system is ready for continuous operation by completing the following simple steps:

1. Turn on the power supply

2. Turn on the CAN instrumentation

3. Read / monitor the temperature

IMPORTANT

Be aware of the following when using the sensor:

• If the sensor is exposed to significant changes in ambient temperature (hot to cold, or cold to hot),

allow 20 minutes for the temperature to stabilise before taking or recording measurements.

• Do not operate the sensor near large electromagnetic fields (e.g. around arc welders or induction

heaters).

Electromagnetic interference can cause measurement errors.

• Wire must be connected only to the appropriate terminals.

Issue A - March 2017

Ihr Schweizer Industriepartner