10

PM180 TOUCH SCREEN INTERFACE MODULE

The PM180 is a temperature indicator, data logger, alarm

unit and configuration tool for Calex infrared temperature

sensors. It is compatible with all models in the PyroBus and

PyroMiniBus series, as well as all PyroMini and FibreMini

models with Modbus output.

The PM180 functions as the Modbus Master on an RS485

network of up to 6 temperature sensors, and can itself be

connected as a slave device to another RS485 network via

a second, isolated Modbus interface. This allows multiple

PM180 units to be multi-dropped to create a large network of

sensors and displays.

Optional alarm relay modules allow the PM180 to be connected to alarm equipment such as

sounders and beacons, and optional analogue output modules allow it to be connected to

non-Modbus instrumentation.

All the configurable parameters for the hub, the connected sensors and the optional output

modules are adjustable via the PM180’s built-in resistive touch screen interface, which can be

operated even with gloves on.

With an optional MicroSD Card inserted, the PM180 functions as a fully-configurable data

logger.

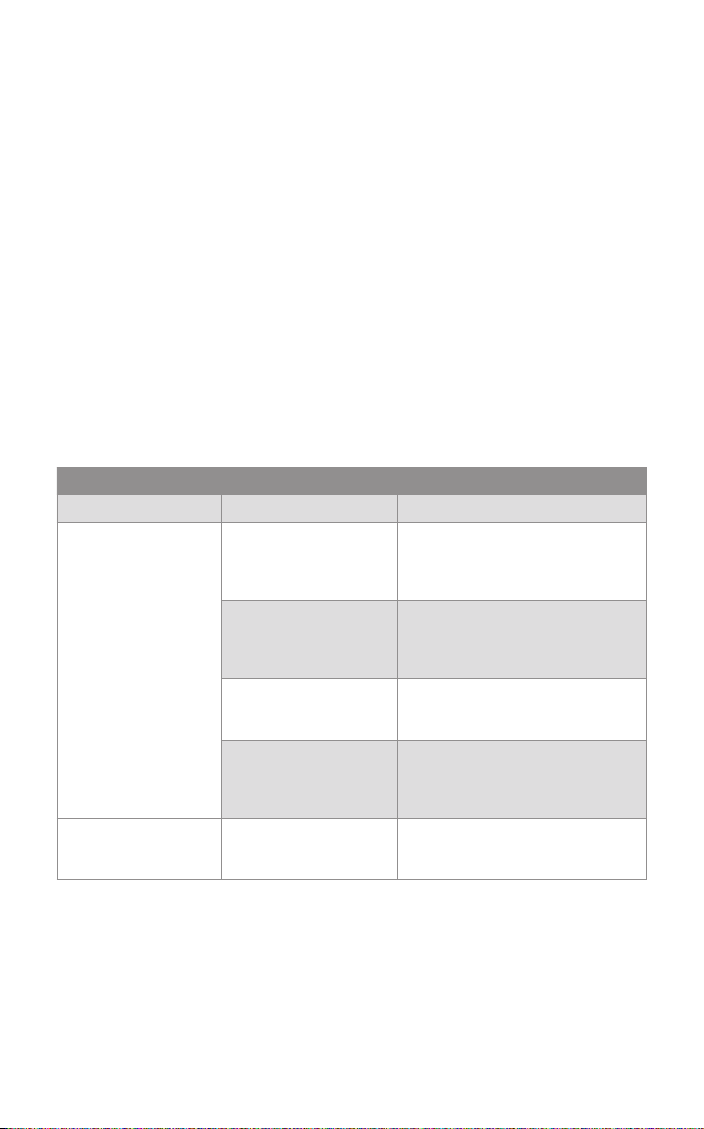

SPECIFICATIONS

Touch Screen Display 2.83” (72 mm) resistive TFT, 320 x 240 pixels, backlit

Supply Voltage 10 to 30 V DC

Maximum Current Draw 100 mA

Ambient Temperature Range 0°C to 60°C

Relative Humidity Maximum 95%, non-condensing

Configurable Parameters

(global)

Temperature units, date and time, data logging, graph

channels, alarm logging

Configurable Parameters (per

channel)

Signal processing, emissivity setting, reflected energy

compensation, alarms, Modbus address

Alarm Configuration 12 alarms (2 per sensor) with adjustable level,

individually configurable as HI or LO.

Temperature Units °C or °F selectable

Temperature Resolution 0.1° below 1000°; 1° above 1000°

Signal Processing Average, peak hold, valley hold, minimum, maximum

Display Sample Period 120 ms per device (720 ms in total for 6 devices)

Compatible Sensor Types PyroBus (all models),

PyroMiniBus (all models),

PyroMini (-BB and -BRT models),

FibreMini (–BRT models)

Compatible Output Module

Types

ICP DAS M-7061 12-channel relay output module,

ICP DAS M-7024 4-channel analogue output module,

selectable V/mA

Dimensions 98(w) x 64(h) x 36(d) mm excluding cable glands

Weight 280 g