The PyroNFC is a non-contact infrared temperature sensor with Near Field Communication

(NFC) capability. It has linear voltage and open collector alarm outputs for connection to

industrial process instrumentation.

By touching an NFC-enabled smartphone against the back of the sensor, the user can

congure the sensor’s settings, and read the measured temperature, via a free app.

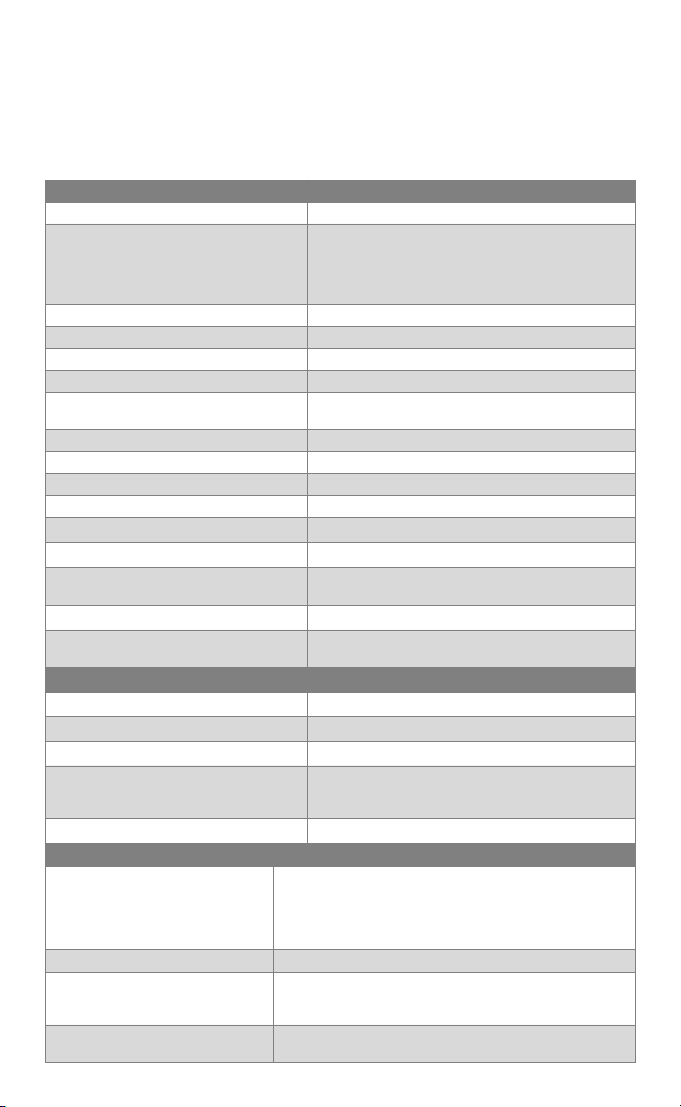

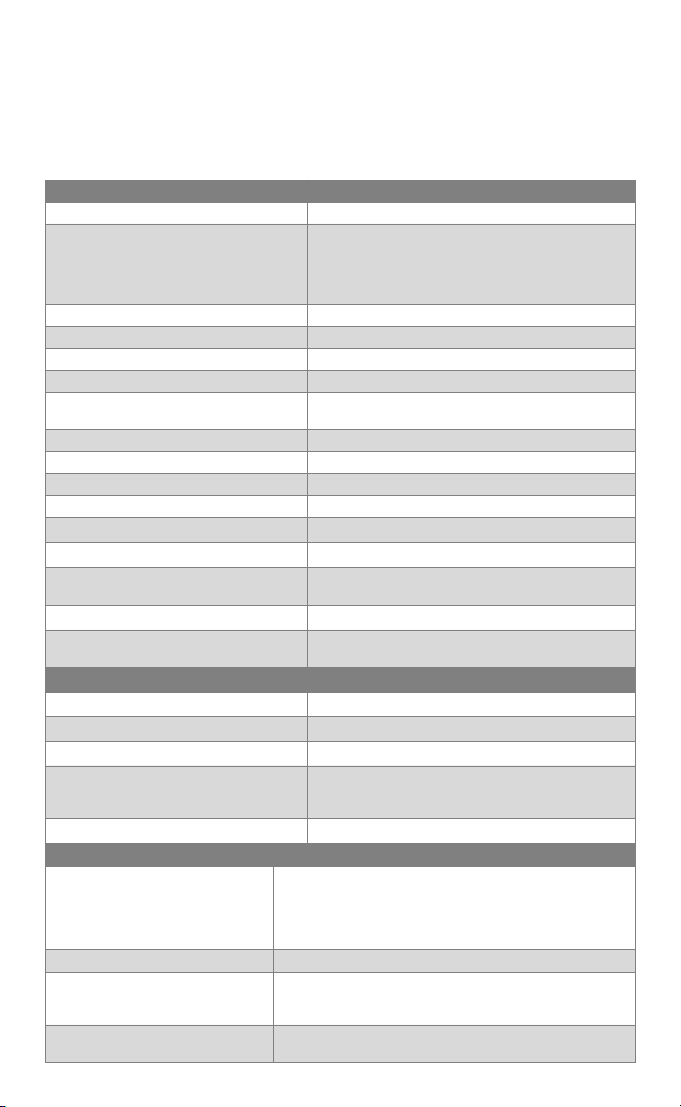

SPECIFICATIONS

General

Temperature Range 0 to 1000°C

Outputs Model PN151: 0-5 V DC, 1-5 V DC or 0-10 V

DC output, linear with measured temperature,

congurable and rescalable via NFC

Model PN151K: Type K Thermocouple

Field of View 15:1 (see OPTICS)

Accuracy ± 1.5% of reading or ± 1.5°C, whichever is greater

Repeatability ± 0.5% of reading or ± 0.5°C, whichever is greater

Response Time 125 ms

Conguration Via iOS or Android app using NFC-equipped

device (e.g. smartphone or tablet)

Emissivity Setting Adjustable via app

Emissivity Setting Range 0.2 to 1.0

Max Temperature Span (Linear Output) 1000°C

Min Temperature Span (Linear Output) 100°C

Spectral Range 8-14 µm

Max. Supply Voltage 28 V DC

Min. Supply Voltage (at Sensor) 12 V DC (for 10 V output)

6 V DC (for 5 V output)

Max Current Draw 7 mA

Warm Up Time (PN151K) Allow 10 seconds after power-on before a reading

is observed.

Environmental & Conformity

Environmental Rating IP65

Ambient Temperature Range 0°C to 80°C

Relative Humidity 95% max. non-condensing

Electromagnetic Compatibility (EMC) EN61326-1, EN61326-2-3 (Electrical Equipment

for Measurement, Control and Laboratory Use -

EMC Requirements - Industrial)

RoHS Compliant Yes

App

Congurable Parameters Temperature range

Linear voltage output type and scale

Alarm output threshold and hysteresis

Emissivity setting

Reected temperature

Temperature Units °C / °F

Signal Processing Averaging Period (0.125 to 60 seconds)

Peak / Valley Hold

Hold Period (0.125 to 120 seconds)

Real Time Temperature Reading Hold NFC device against sensor for continuous in- app

temperature updates

2