33

Installation

WARNING

WARNING. For metal sheathed heaters, insulation

contamination or moisture accumulation can cause

fault to the element sheath generating arcing and

releasing molten metal. Install proper ground fault

protection to prevent personal injury and/or property

damage.

3. When mounting, maintain a minimum clearance to

combustibles of 15” (381 mm) at sides, 10”(254 mm) at top

and 12” (305 mm) at ends.

CCI Thermal Technologies Inc. 1 Hunter Valley Road, Orillia, ON L3V 6H2 Tel. (705) 325-3473 Fax (705) 325-2106

www.ccithermal.com

MI430 REV.0 Page 1 of 3

INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS FOR

SERIES OKA – INFRARED RADIANT HEATERS

FIRE/EXPLOSION HAZARD WARNING - During operation, take precautions to ensure that

combustible materials are always kept at a safe distance from the radiant energy. This heater is

not intended for use in hazardous areas where flammable vapours, gases or liquids or other

combustibles are present. Remember that objects placed under an infrared heater can take a while

to reach stabilized temperatures. If you are unsure of the suitability of the heater for the intended

application, check with the factory for recommendations. Failure to comply can result in personal

injury and/or property damage.

DESCRIPTION

1.0 The OKA radiant heater is suitable for process heating in

non-hazardous areas protected from rain, snow or splashing, where

heating element temperatures in excess of 1382°F(750°C) will not

present the risk of fire or explosion. This heater is not intended for

use in comfort heating applications.

2.0 The OKA heater is available with metal sheathed, quartz

lamp or quartz tube heating elements. Use heaters with metal

sheathed elements where there is heavy vibration or mechanical

shock. Quartz tube or quartz lamp elements are very fragile and

require extreme care in handling. Heaters utilizing quartz tubes or

quartz lamps are unsuitable for applications in locations where the

risk of heavy vibration or mechanical shock exists.

3.0 To avoid damage in transit, heaters with quartz lamp or

quartz tube elements are shipped with the elements not installed in

the fixture.

4.0 A minimum of handling of the quartz sheath is

recommended since any type of contamination on the sheath may

reduce service life.

5.0 On CE marked heaters which are being installed in the EU, the

installation of heater shall be in accordance with the Low Voltage

Directive 73/23/EEC, and any applicable local jurisdictional

requirements.

INSTALLATION

The system designer is responsible for

the safety of this equipment and

adequate back-up controls and safety

devices must be installed. Failure to

comply could result in personal injury

and/or property damage.

Heaters must be wired by qualified

personnel in compliance with local

codes.

6.0 Verify that the nameplate voltage and wattage are suitable

for use on the available electrical power supply. Do not connect the

heater to an electrical supply voltage other than shown on the product

label.

7.0 For metal sheathed heaters, install proper ground fault

protection to prevent personal injury and/or property damage.

For metal sheathed heaters, insulation

contamination or moisture

accumulation can cause fault to the

element sheath generating arcing and

releasing molten metal. Install proper

ground fault protection to prevent

personal injury and/or property

damage.

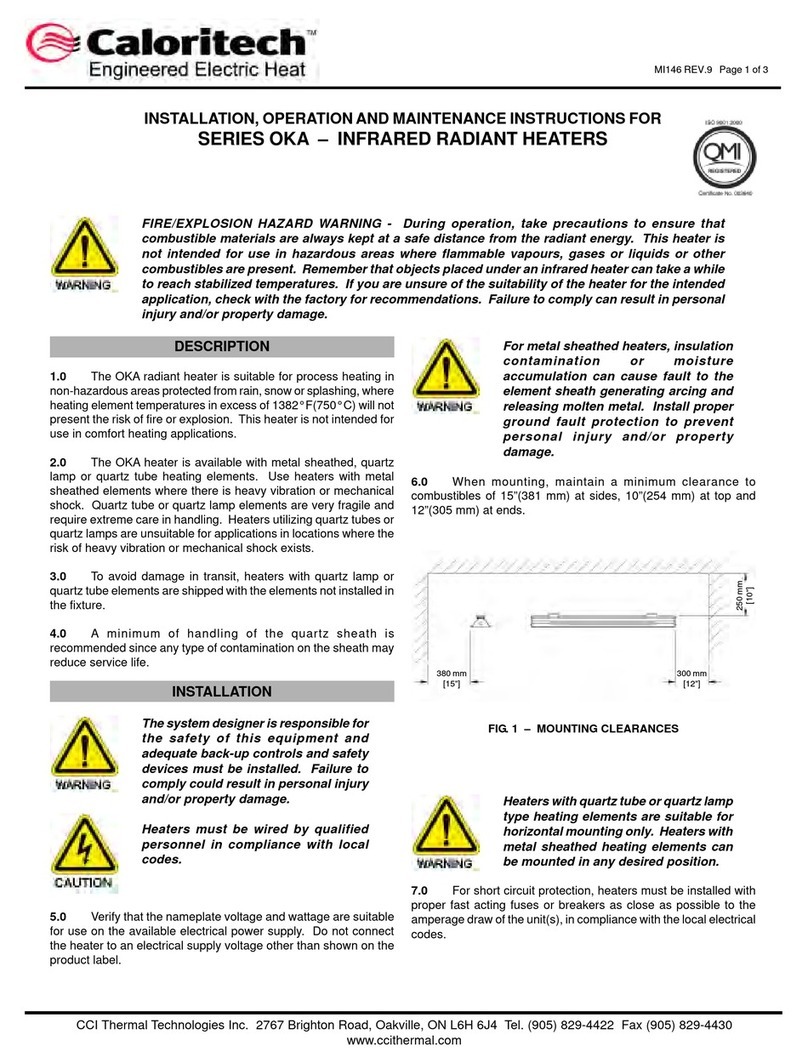

8.0 When mounting, maintain a minimum clearance to combustibles

of 15”(381 mm) at sides, 10”(254 mm) at top and 12”(305 mm) at ends.

Heaters with quartz tube or quartz lamp

type heating elements are suitable for

horizontal mounting only. Heaters with

metal sheathed heating elements can

be mounted in any desired position.

9.0 For short circuit protection, heaters must be installed with

proper fast acting fuses or breakers as close as possible to the

amperage draw of the unit(s), in compliance with the local electrical

codes.

380 mm

[15”]

300 mm

[12”]

250 mm

[10”]

FIG. 1 – MOUNTING CLEARANCES

Figure 1 – Mounting clearances

WARNING

WARNING. Heaters with quartz tube or quartz lamp

type heating elements are suitable for horizontal

mounting only. Heaters with metal sheathed heating

elements can be mounted in any desired position.

4. For short circuit protection, heaters must be installed with

proper fast acting fuses or breakers as close as possible

to the amperage draw of the unit(s), in compliance with the

local electrical codes.

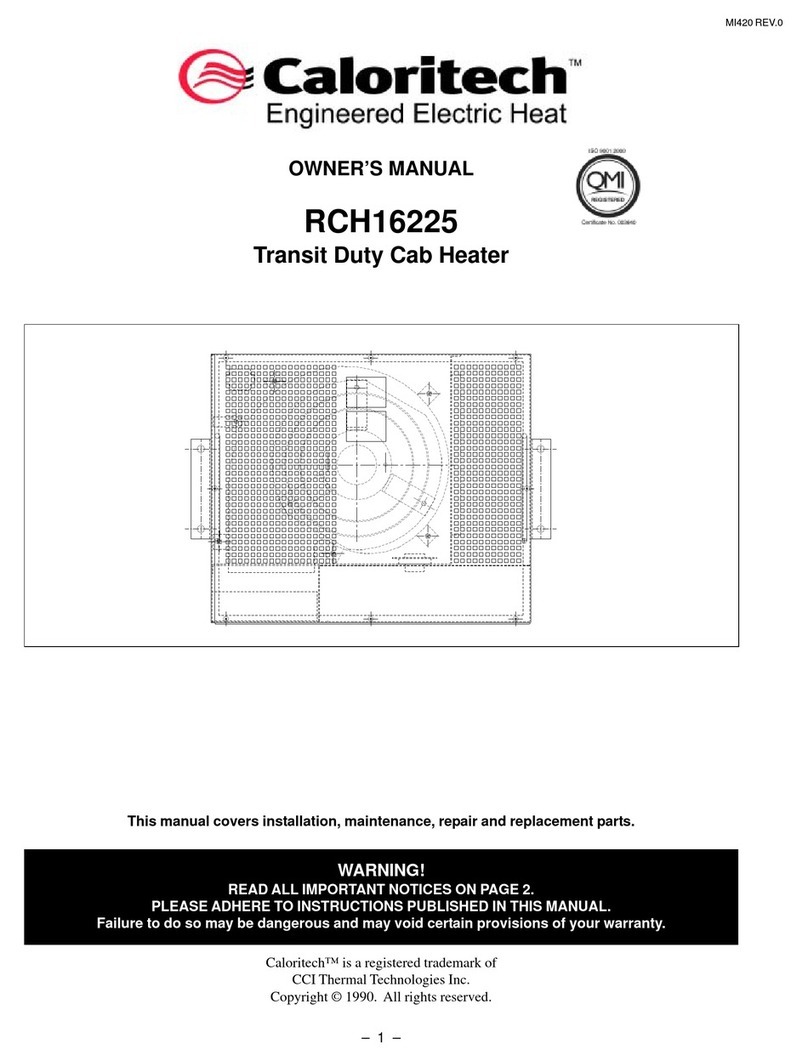

5. Two sliding mounting pads are provided with each heater.

6. The mounting pads have a ¼”-20 tapped hole which

can be utilized to attach the heater to a suitable non-

combustible support positioned as in paragraph 2 of

Section B. Installation.

CCI Thermal Technologies Inc. 1 Hunter Valley Road, Orillia, ON L3V 6H2 Tel. (705) 325-3473 Fax (705) 325-2106

www.ccithermal.com

MI430 REV.0 Page 2 of 3

10.0 Two sliding mounting pads are provided with each heater.

The mounting pads have a ¼”-20 tapped hole which can be utilized to

attach the heater to a suitable non-combustible support positioned as

in paragraph 7.0.

OPERATION

For metal sheathed heaters, prior to

operation an insulation resistance

check must be performed. Heater with

values less than 1 MΩΩΩΩΩ should follow a

drying process. Please contact factory

for details on procedure if heater is

under 1 MΩΩΩΩΩ.

15.0 Energize the heater at the voltage shown on the nameplate

and visually check the element to ensure that it slides freely on

expansion. A small sag is normal, especially on longer heaters.

16.0 Heaters with metal sheathed elements which have not been

energized for a prolonged period shall be restarted under close

supervision for the first thirty minutes of operation.

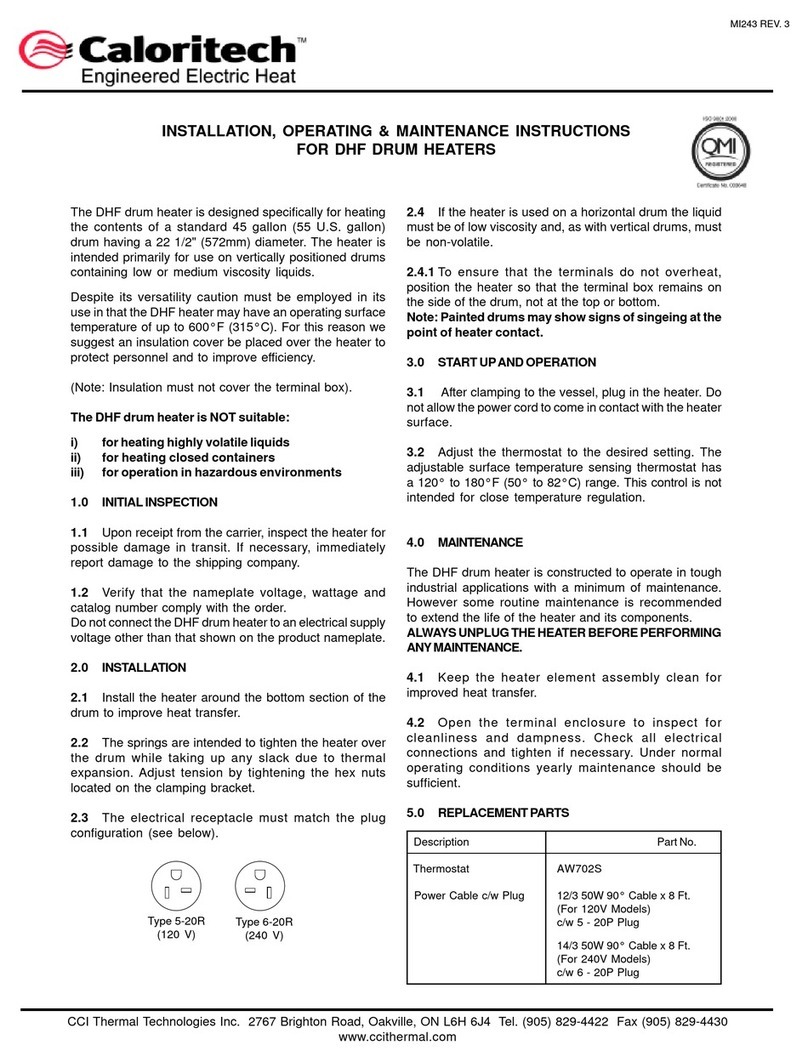

FIG. 3 – TYPICAL WIRING ATTACHMENT

OF QUARTZ HEATER

ELEMENT LEAD WIRE

TERMINATE WITH VERY

LITTLE SLACK

QUARTZ TUBE

OR LAMP

ELECTRICAL

TERMINAL

POWER

WIRE

RETAINER

BRACKET KEEPER

SCREW

CERAMIC ELEMENT HOLDER

11.0 The connection boxes at the ends of the heater each have a

volume of 12 in³(196 cm³).

12.0 Heater is provided with 15” long pig tail lead wires suitable for

200°C that must be terminated in a remote junction box. Supply

connectors into the remote junction box must be suitable for

194°F(90°C), or, alternately the heater may be wired with 200°C supply

wire. The ground wire from the supply shall be connected to the

grounding connection located in the box at one end of the heater.

13.0 To facilitate wiring, a ½” NPT tapped hole is provided at each

end of the heater extrusion. A duplex conduit connector or T type

junction box attached to either mounting hole will simplify wiring of

single or multiple units. For type R heaters, which have both terminals

at one end in a moisture resistant housing, use rigid conduit to ensure

moisture protection.

14.0 Follow this procedure and Fig. 3 when installing the quartz

tube or lamp:

14.1 Disconnect power at source.

14.2 Remove the terminal covers at each end of the heater.

14.3 Remove the keeper screw on one retainer bracket and slide

the ceramic element holder aside.

14.4 Feed the element lead wire through the hole in the ceramic

holder at the fixed end first. Slide the ceramic holder removed in 14.3

over the element so that the element is captured in both ceramic

holders and then reinstall the keeper screw.

14.5 Loosen the electrical terminal nut on the ceramic blocks to

permit connection of the power and lead wires.

14.6 To connect the element lead wires, slide the ceramic holders

as far as possible toward the centre of the fixture and loop the

element wire over the electrical terminal leaving very little slack in

the wire. Note that the ceramic blocks are designed to slide freely

with element thermal expansion and the taut lead wires help to

secure the element in place.

14.7 Connect the power wires to the electrical terminals and install

terminal covers.

14.8 Before energizing, wipe the quartz sheath and reflector with

a cloth or paper towel dampened with alcohol.

MAINTENANCE

Disconnect all power before installing

or servicing the heater. Failure to do so

could result in personal injury and/or

property damage. All maintenance and

installation should be done by qualified

personnel in compliance with local

codes.

17.0 As a safety precaution and to avoid non-scheduled

downtimes, replace the heating element if a pronounced hot spot

(area of the element that glows brighter) is visible along its heated

section.

For metal sheathed heaters, after

performing maintenance, and prior to

energization, an insulation resistance

check must be performed. Heater with

values less than 1 MΩΩΩΩΩ should follow a

drying process. Please contact factory

for details on procedure if heater is

under 1 MΩΩΩΩΩ.

5 cm

[2”]

4.4 cm

[1¾”]

SLIDING MOUNTING PAD

WITH ¼”-20 TAPPED HOLE

FIG. 2 – TYPICAL HEATER ATTACHMENT

Figure 2 – Typical heater attachment

7. The connection boxes at the ends of the heater each have

a volume of 12 in³ (196 cm³).

8. Heater is provided with 15” long pig tail lead wires suitable

for 200°C that must be terminated in a remote junction

box. Supply connectors into the remote junction box must

be suitable for 194°F (90°C), or, alternately the heater

may be wired with 200°C supply wire. The ground wire

from the supply shall be connected to the grounding

connection located in the box at one end of the heater.

9. To facilitate wiring, a ½” NPT tapped hole is provided

at each end of the heater extrusion. A duplex conduit

connector or T type junction box attached to either

mounting hole will simplify wiring of single or multiple units.

For type R heaters, which have both terminals at one end

in a moisture resistant housing, use rigid conduit to ensure

moisture protection.

10. Follow this procedure and Fig. 3 when installing the quartz

tube or lamp:

10.1 Disconnect power at source.

10.2 Remove the terminal covers at each end of the

heater. Remove the keeper screw on one retainer

bracket and slide the ceramic element holder aside.

10.3 Feed the element lead wire through the hole in

the ceramic holder at the fixed end first. Slide the

ceramic holder removed in paragraph 10.2 over

the element so that the element is captured in both

ceramic holders and then reinstall the keeper screw.

10.4 Loosen the electrical terminal nut on the ceramic

blocks to permit connection of the power and

lead wires.

10.5 To connect the element lead wires, slide the ceramic

holders as far as possible toward the centre of the

fixture and loop the element wire over the electrical

terminal leaving very little slack in the wire. Note that

the ceramic blocks are designed to slide freely with

element thermal expansion and the taut lead wires

help to secure the element in place.

10.6 Connect the power wires to the electrical terminals

and install terminal covers.

10.7 Before energizing, wipe the quartz sheath and

reflector with a cloth or paper towel dampened with

alcohol.

11. Wire guard (if required) to be installed per Figure 3,

page 3. When installed, the wire guard should move

freely on the reflector.

Figure 3 – Correctly installed wire guard

Figure 4 – Incorrectly installed wire guard