E-Series Technical Manual 5 Cambridge Air Solutions

RECEIVING:

Upon receipt, examine units carefully for in-transit

damage or missing components as detailed in packing

list. If damaged, report damage(s) to trucking company,

take pictures, and contact Cambridge Air Solutions.

After uncrating unit, verify that it is the proper size and

that all loose parts are included.

NOTE: Inspect the exterior and interior of the equipment

carefully for any damage that may have occurred during

shipment. Verify shipped loose parts are complete and

undamaged. Ensure there is no damage to protruding

exterior components such as door handles, disconnect

switch handle, etc. or to internal components such as

pumps, media, filters, louvers and drains.

INSTALLATION:

WARNING:

Do not remove unit from shipping skid until it

is at the installation location. Moving these units

when not properly secured to the skid can result in

personal injury or death and can seriously damage

the unit.

WARNING:

To prevent injury or death, and damage to unit,

ensure the lifting capacity of the moving equipment

exceeds the weight of the unit by an adequate

safety margin.

NOTE: Ensure all local building and electrical codes are

fully complied with in installing the unit.

Take the following factors into consideration before

selecting the location of installation:

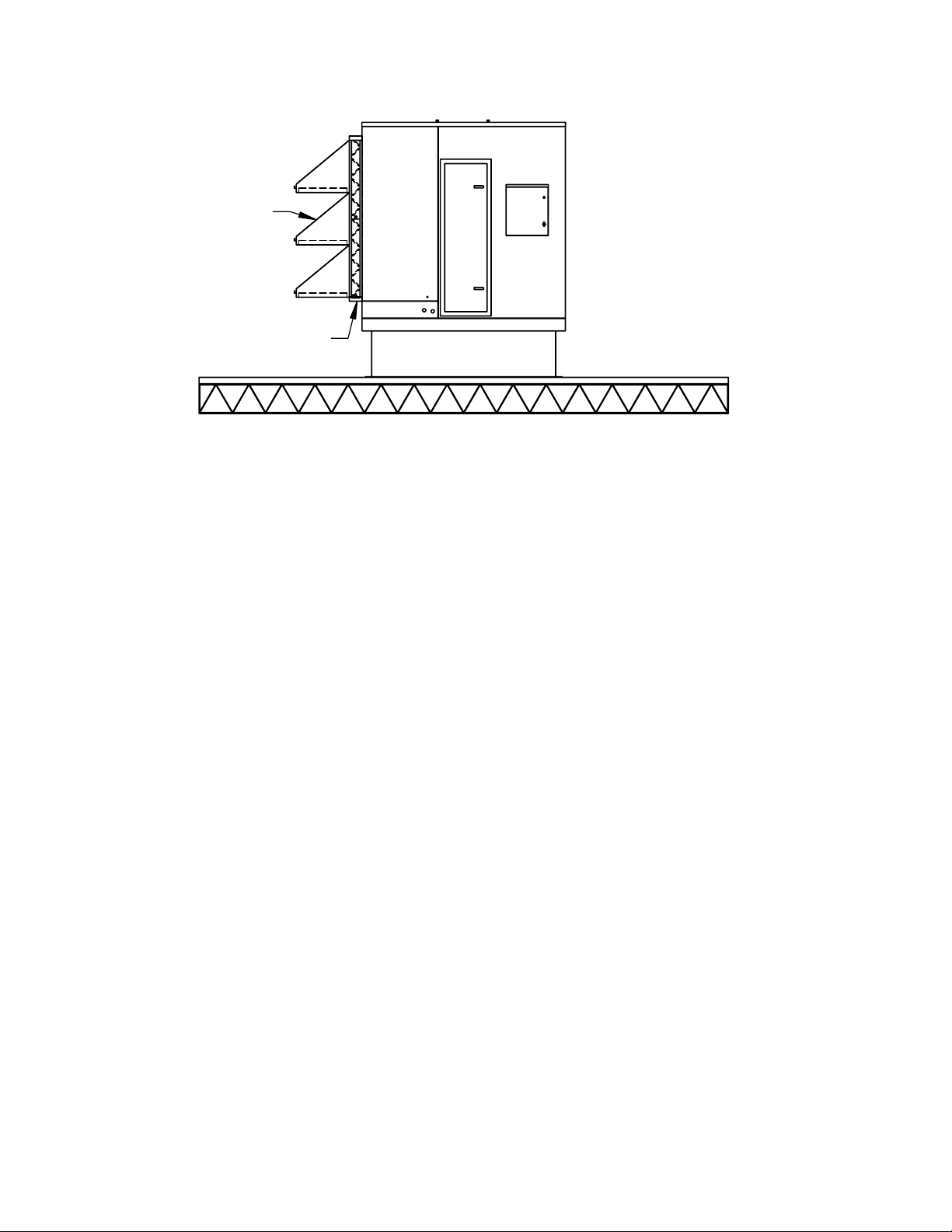

• Ensure sufficient clearance, per the submittal, to

allow easy access for maintenance and system

operation.

• Unit must be installed on a level foundation

that allows for proper flow of condensation into

internal drains, sufficient to support continuous

to full perimeter of base and cross members, and

minimize deflection of unit base frame to no more

than 1/16th “ (1.6mm) over the length and width of

unit.

WARNING:

To prevent injury or death, disconnect electrical

power source before completing connection to

the unit. All wiring must comply with National

Electrical Code (NEC) and state and local

requirements. Outside the United States, the

national and or local electrical requirements of

other countries shall apply.

The installing contractor must connect appropriate

power wiring to the terminal block or non-fused,

unit-mounted disconnect in the power section of

the unit control panel.

WARNING:

During installation, testing, servicing, and

troubleshooting of this product, it may be necessary

to work with live electrical components. To

prevent injury or death due to electrocution, take

extreme care when performing service procedures

with electrical power energized. Have a qualified

licensed electrician or other individual who has

been properly trained in handling live electrical

components perform these tasks. Failure to

follow all safety precautions when exposed to

live electrical components could result in death or

serious injury.

1. All installation should be performed in accordance to

local and state codes and with proper permits.

2. Measure the unit for correct sizes compared to the

submittal. Immediately contact Cambridge Air

Solutions if the unit’s openings do not match.

3. Check for proper air flow direction.

4. Set the unit in place. Make sure the unit covers the

entire air inlet opening.

5. Fasten the unit in place with the self-drilling screws

provided with the unit.

NOTE: Take care not to drill or screw into sump tank.

6. Check for air leakage. Air leakage will lower the

efficiency of the unit.

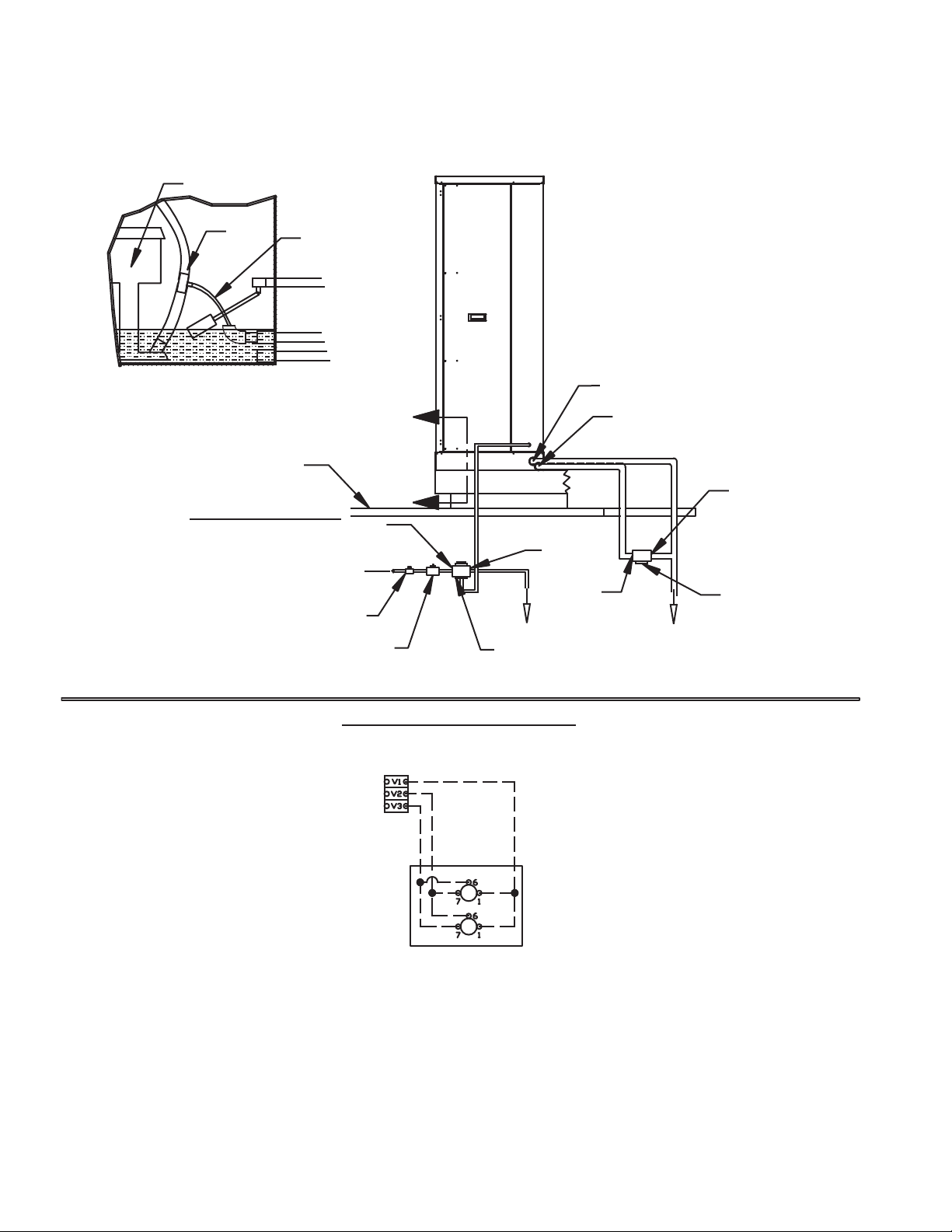

7. Check that the unit is level for proper water transfer

through the system.

8. Check that the sump pump has a good seal to the

floor.