2

Safety

Before installing this product, become familiar with the installation instruc-

tions presented in Section 3 and all safety notes throughout.

! WARNING:Thissymbolidentiesinformationaboutpracticesorcircum-

stances that can lead to personal injury or death, property damage, or

economic loss.

CAUTION: Indicates actions or procedures which if not performed correctly

may lead to personal injury or incorrect function of the instrument

or connected equipment.

IMPORTANT: Indicates actions or procedures which may affect instrument operation or

may lead to an instrument response that is not planned.

Startup Procedure....................................................................................... 17

Shutdown Procedure .................................................................................. 18

Section 4—Calibration and Maintenance................................................... 19

General Field and Periodic Maintenance.................................................... 19

Electronic Transmitter.............................................................................. 19

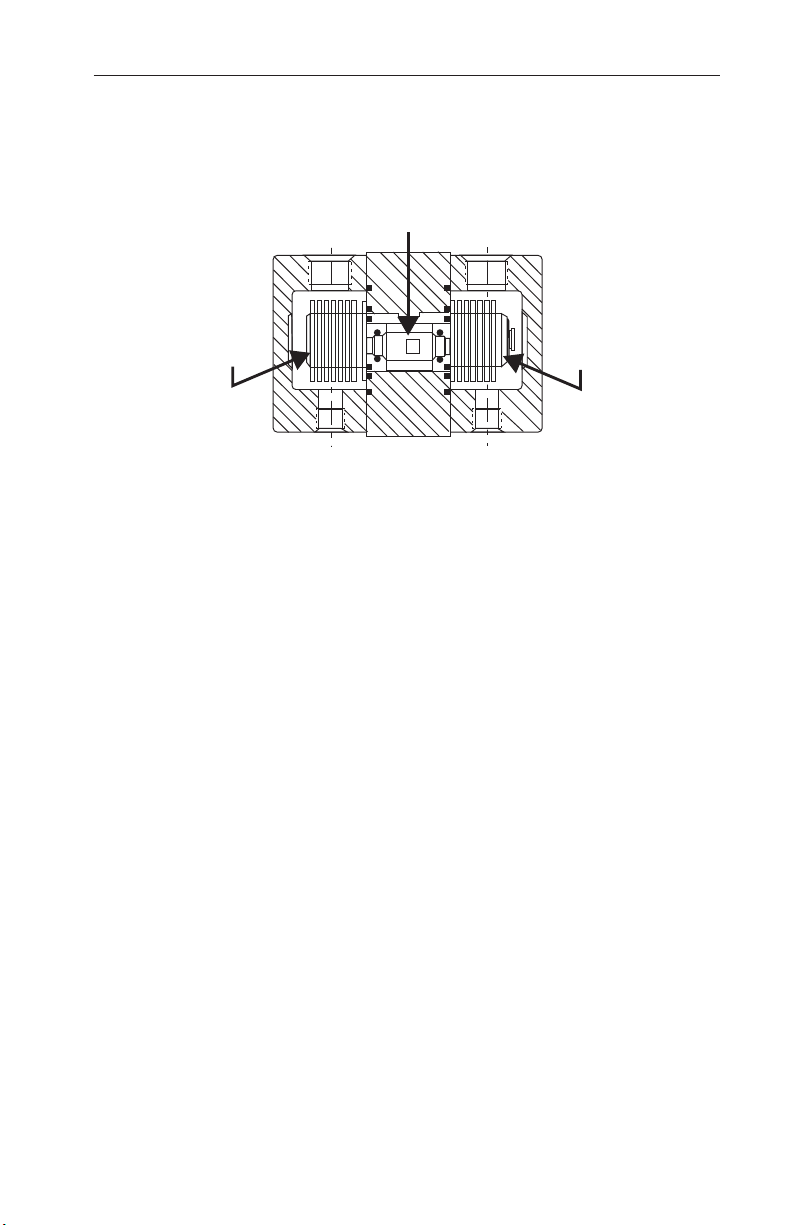

Differential Pressure Unit (DPU) ............................................................. 19

Calibration .................................................................................................. 19

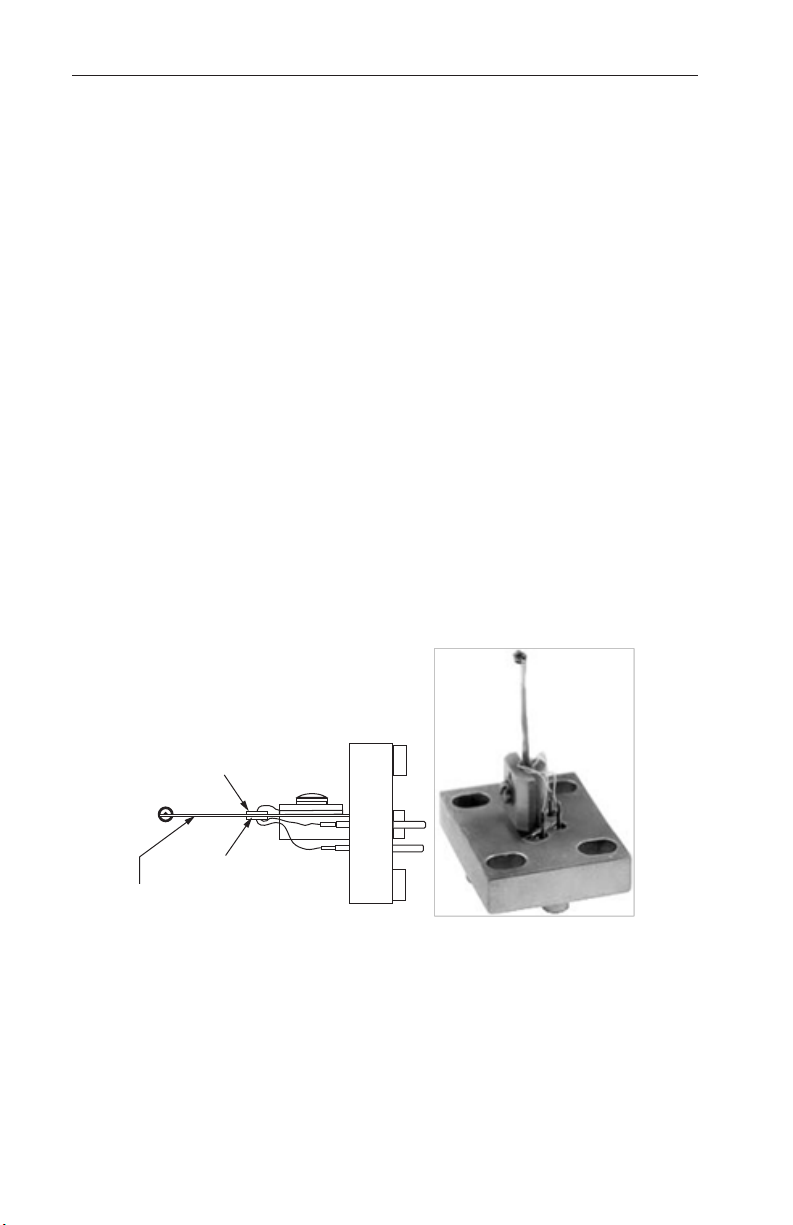

Electrical Connections for Calibration ..................................................... 20

Calibration Checkpoints .......................................................................... 21

Calibration Procedure ............................................................................ 21

DPU Inspection and Cleaning..................................................................... 22

Troubleshooting .......................................................................................... 23

Section 5—Assembly Drawing and Parts List........................................... 27

Section 6—Dimensional Drawings ............................................................. 31

Appendix A...................................................................................................A-1

Safety Precautions.....................................................................................A-1

Flow Application .....................................................................................A-1

Liquid Level Applications........................................................................A-1

Typical Piping/Startup Examples ...............................................................A-2

Gas Flow, DPU Above Run ....................................................................A-2

Gas Flow, DPU Below Run ....................................................................A-3

Gas Flow, Hydrates Present...................................................................A-4

Steam Flow, DPU Below Run.................................................................A-5

Liquid Flow, DPU Above Run .................................................................A-6

Liquid Flow, DPU Below Run .................................................................A-7

DPU Below Tank with Reference Leg: Hot or Cool Liquids....................A-8

DPU Level with Tank Bottom: Cool Liquids with Pressurized Tank ........A-9

DPU Below Tank Bottom: Cool Liquids with Pressurized Tank ............A-10

Product Warranty .....................................................................................A-11

Product Brand............................................................................................................

A-11