BARTON®MODEL 753A

GAGE PRESSURE TRANSMITTER

User Manual

Part No. 9A-10840, Rev. 02

March 2020

Contents

Safety............................................................................................................ 2

Section 1—Introduction................................................................................. 3

General ......................................................................................................... 3

Product Description....................................................................................... 3

Gage Pressure Transducer ...................................................................... 3

Electronic Transmitter................................................................................ 3

Power Supply ............................................................................................ 4

Zero and Span Control.................................................................................. 4

Zero Control .............................................................................................. 4

Span Control ............................................................................................. 4

Specications ............................................................................................... 5

Section 2—Theory of Operation.................................................................... 7

Basic Components........................................................................................ 7

Gage Pressure Transducer ....................................................................... 7

Electronic Transmitter................................................................................ 7

Basic Operation ............................................................................................ 7

Surge Voltage Protection Circuit .............................................................. 8

Reverse Polarity Protection....................................................................... 8

Regulator................................................................................................... 8

Strain Gage Bridge Network ..................................................................... 8

Signal Amplier.......................................................................................... 9

Current Amplier........................................................................................ 9

Temperature Compensation.......................................................................... 9

Section 3—Installation, Startup, and Shutdown........................................ 10

Overview..................................................................................................... 10

Unpacking/Inspection.................................................................................. 10

Initial Calibration Check .............................................................................. 10

Mounting ..................................................................................................... 10

Wall or Rack Mounting ............................................................................ 10

Piping Guidelines.........................................................................................11

Electrical Connections ................................................................................11

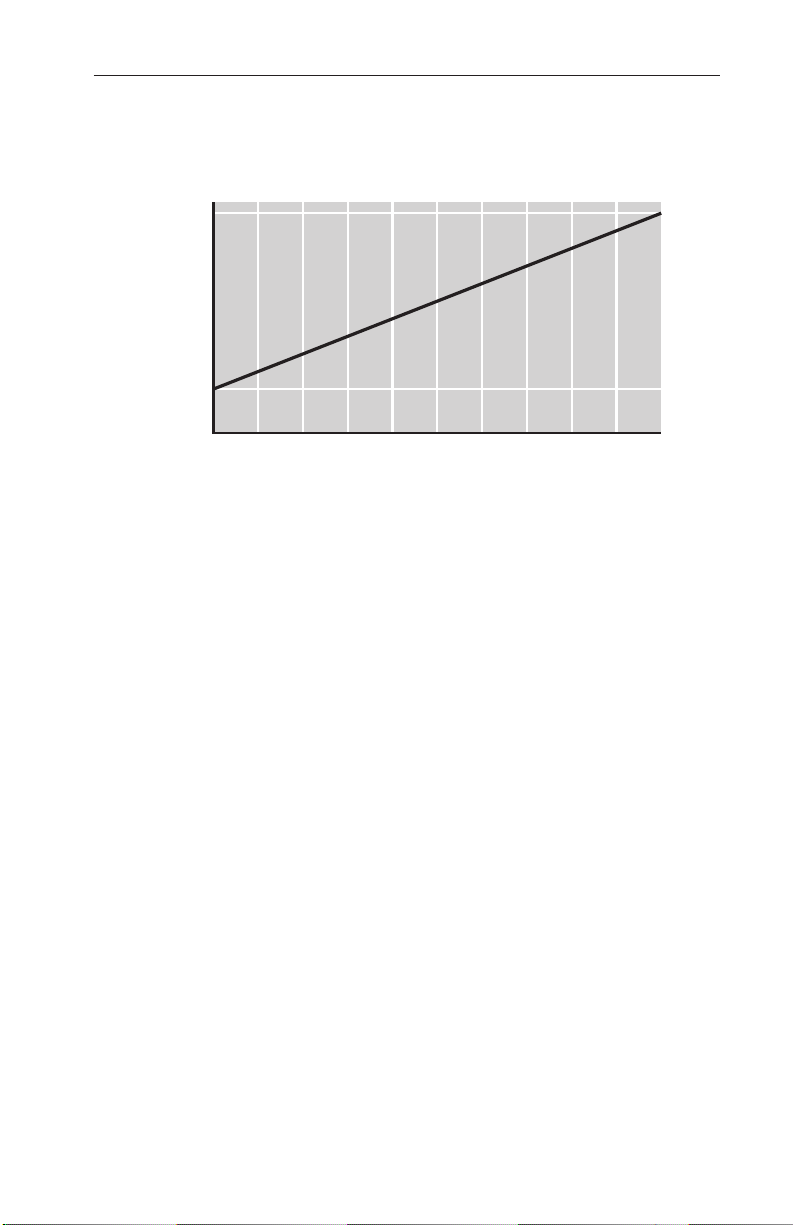

Loop Resistance Calculations................................................................. 13

Maximum Loop Resistance..................................................................... 14