#1

MARKING - MARCATURA - MARQUAGES - KENNZEICHNUNG - MARCAJE - MARCAÇÃO - AANDUIDING -

MÄRKNING - MERKING - MERKINTÄ - MARCAJUL - OZNACZENIA - OZNAČENÍ - OZNAČENIE - OZNAKA -

OZNAČAVANJE - - MARKALAMA - МАРКИРОВКА 标记 - 規格適合 - 마킹 - เครืองหมายสญั ลกั ษณ์ตา่ งๆ _______ 2

NOMENCLATURE - NOMENCLATURA - NOMENCLATURE - NOMENKLATUR - NOMENCLATURA -

NOMENCLATURA - TERMINOLOGIE - KOMPONENTFÖRTECKNING - BETEGNELSER - OSALUETTELO -

NOMENCLATURA - NAZEWNICTWO - SEZNAM ČÁSTÍ - ZOZNAM ČASTÍ - SEZNAM IZRAZOV -

NOMENKLATURA - СОСТАВНЫЕ ЧАСТИ - TERİMLER - 各部位名称 - 各部の名称 - 사용이름 -

ระบบชือของสว่ นประกอบ __________________________________________________________________________ 4

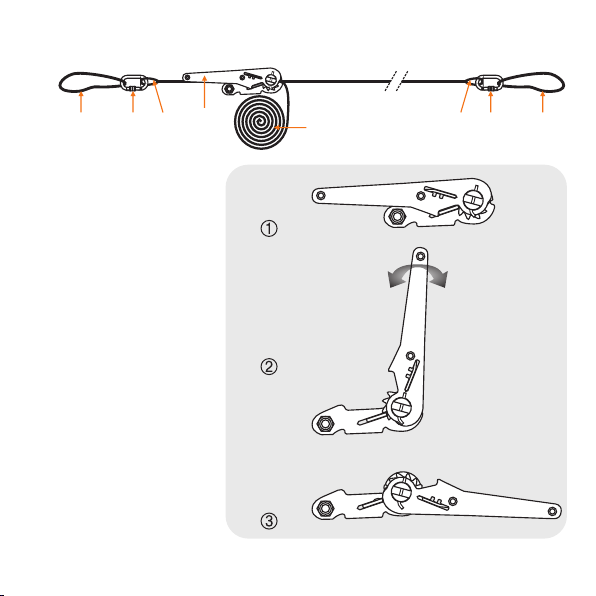

FIGURES - FIGURE - FIGURES - ABBILDUNG - FIGURAS - FIGURAS - FIGUREN - FIGURER - FIGURER -

KUVAT - FIGURI - RYSUNKI - OBRÁZKY - OBRÁZKY - SLIKE - SLIKE - РИСУНКИ - ŞEKİLLER - 图 - 図 - 그림

- รูปภาพ ___________________________________________________________________________________ 6

ENGLISH _______________________ 14

ITALIANO _______________________ 18

FRANÇAIS _______________________ 22

DEUTSCH _______________________ 26

ESPAÑOL _______________________ 32

PORTUGUÊS _______________________ 37

NEDERLANDS _______________________ 42

SVENSKA _______________________ 47

NORSK _______________________ 52

SUOMI _______________________ 57

ROMÂNĂ _______________________ 62

POLSKI _______________________ 67

ČEŠTINA _______________________ 72

SLOVENČINA _______________________ 77

SLOVENSKI _______________________ 82

HRVATSKI _______________________ 87

РУССКИЙ _______________________ 91

TÜRKÇE _______________________ 97

漢語 _______________________ 102

日本語 _______________________ 107

한국어 _______________________ 113

ภาษาไทย _______________________ 118

LIFE SHEET - SCHEDA DI VITA - FICHE DE DURÉE DE VIE - DATENBLATT - FICHA DE LA VIDA ÚTIL - FICHA

DA VITA ÚTIL - ONDERHOUDSKAART - INFORMATIONSKORT - PRODUKTKORT - TUOTTEEN

TARKASTUSLOMAKE - FIŞA DE DURABILITATE - KARTA WYROBU - PROVOZNÍ LIST - ZÁZNAM KONTROL -

KONTROLNI LIST - SERVISNI LIST - БЛАНК ОСМОТРА - KULLANIM KARTI - 使用寿命卡 - ライフシート - 수

명도표 - แผน่ บนั ทกึ การใช้งานผลติ ภณั ฑ์ ______________________________________________________________ 128