8

Goodhabitsfornormaldrivingneedextraemphasiswhen

towing.Theadditionalweightaectsaccelerationandbraking,andextra

timeshouldbeallowedforpassing,stopping,andchanginglanes.Signal

wellinadvanceofamanoeuvretoletotherdriversknowyourintentions.

Severebumpsandbadlyundulatingroadscandamageyourtowing

vehicle,hitch,andtrailer,andshouldbenegotiatedataslowsteadyspeed.

Donotattempttotowanytypeof

trailerbehindanothertrailer.Towingmultipletrailersmaycausesevere

instability,lossofcontroland/orstructuralfailure,andmayresultinvehicle

accidents,propertydamageandpersonalinjury.Towingmultipletrailersis

illegalinmanyjurisdictions.

.Severe

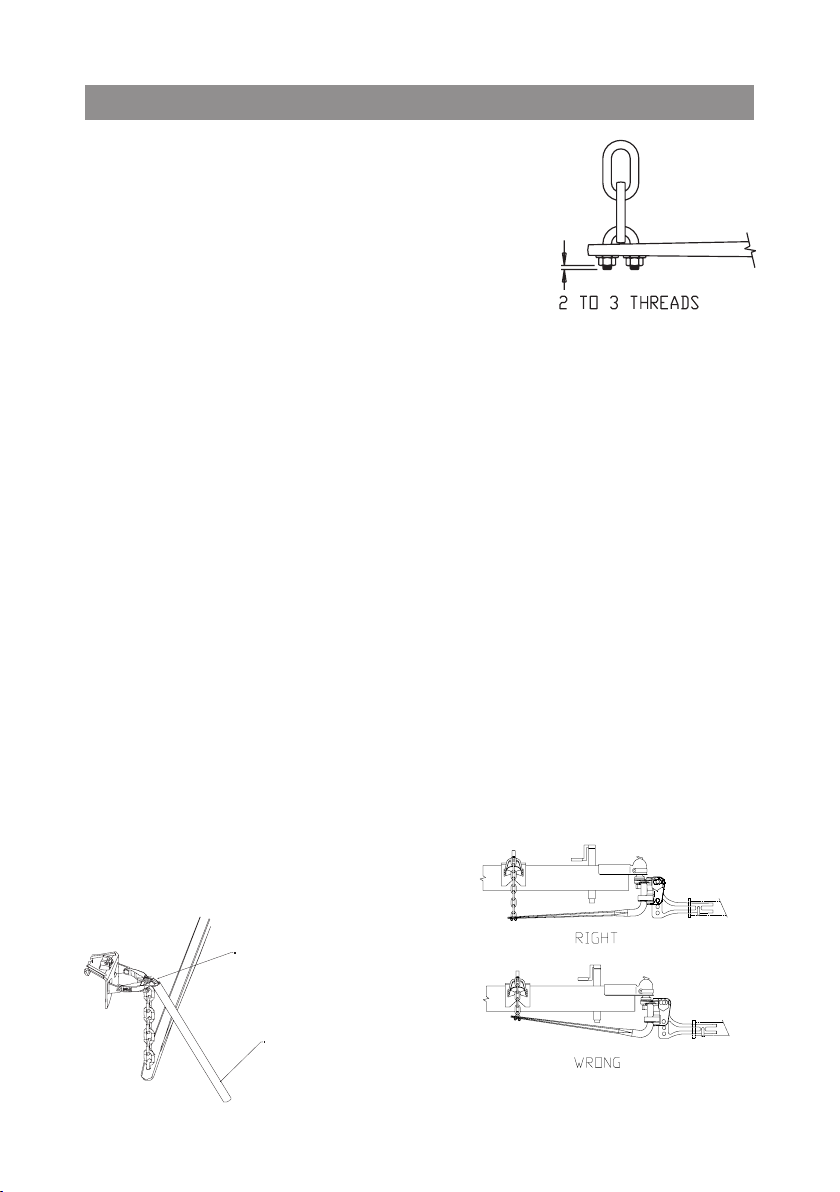

structuraldamagetotowingvehicle,hitch,andtrailermayresult.Atowing

vehicle/trailercombinationcannotbecontrolledadequatelyunlessthe

towingvehicle’srearwheelsarecarryingtheirshareoftheload.

Keepthetrunnionsandsocketsintheheadassemblyfreeofdirtandwell

lubricated.Excessivewearinthisareamayindicateoverloadorinadequate

lubrication.Someelongationofsocketopenings“seatin”isnormal.

Keeptheheadassemblyexteriorclean,especiallythetrunnionsockets.Do

notallowdirtorstonestolodgebetweenthetrunnionsandthehead.

Keepthehitchpaintedtopreventrustandmaintainagoodappearance.(Do

notpaintoverlabels)

•Addadropofoilatthetrunnioncontactareaswithballmount.

•Cleantheballandcouplersocketandcoattheballlightlywithgrease.

•CheckspringbarchainsandU-boltsforwear.Replacethembeforethey

becomewornhalfwaythrough.

•Checktoseethatallboltsareproperlytightenedandthatthehitchpinand

cliparesecurelyinplace.

•Checktoseethatelectricalhookupsareinworkingorder,andthatsafety

chainsareconnected.