The Panther 5405 is designed to reproduce, at a smaller scale, an aiming test screen compliant with the Standard SAE J599

(revised Aug. 1997). The beam projections appear on the internal screen of the aimer as they would appear on a screen located 25

feet from the headlamps.

The aiming screen complies with all aiming and inspection requirements of the Standards SAE J599 (revised August 1997) and SAE J600

(revised February 1993).

With the lines drawn on the internal screen of the aimer, all aiming and testing procedures can be performed according to the inspection

limits described in the Standards.

In addition, the European type lighting can also be aimed.

Aiming Procedures

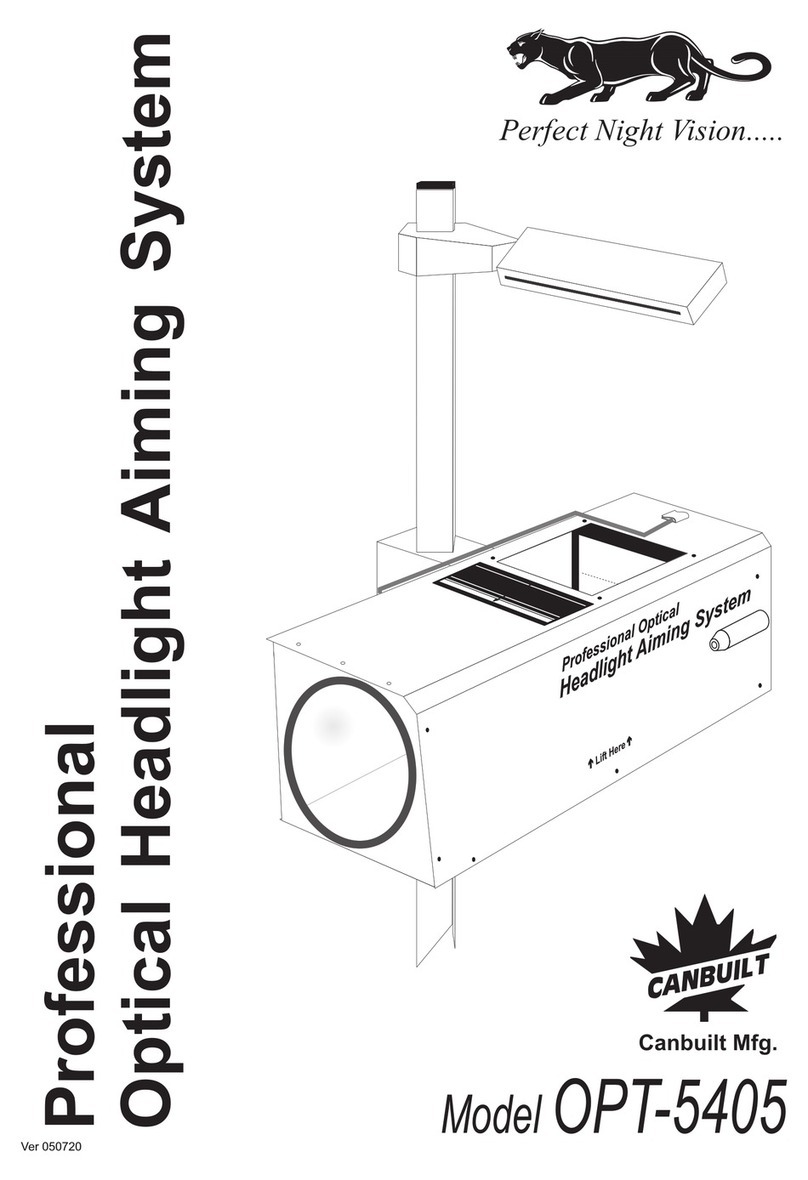

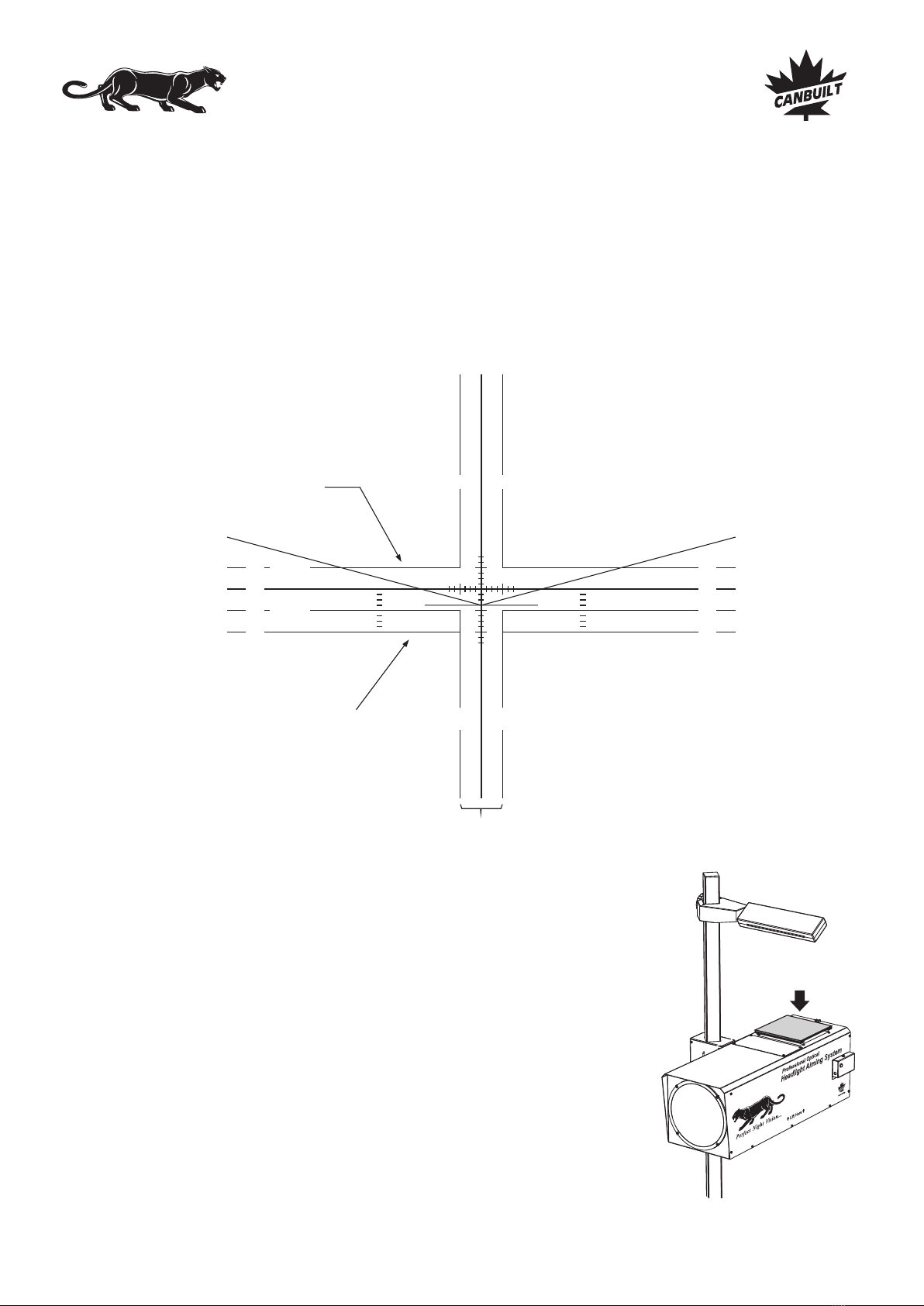

DESCRIPTION OF THE INTERNAL SCREEN OF THE AIMER

Horizontal line used as low beam

inspection upper limit.

Biased line for the

European type low beam

Horizontal line used as low

beam inspection lower limit.

Two vertical lines used as low beam lateral inspection limits

100 mm

100 mm

100

mm

100

mm

4" 4"

4"

4"

8"

0"

4"

4"

8"

0"

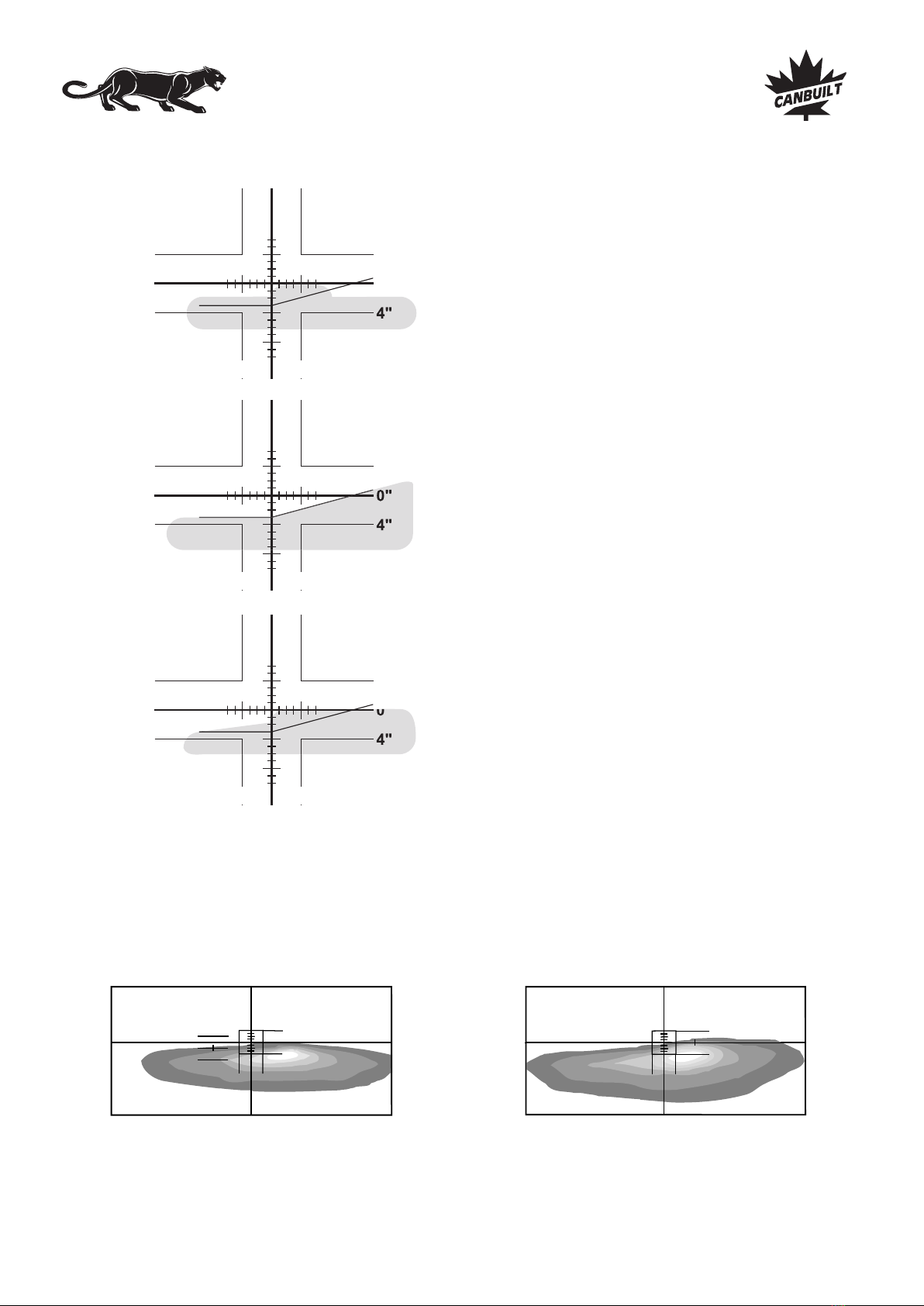

Due to the widely varying light intensity and color of automotive headlights, and different

operators sensitivity to light, it is difficult to locate the light beam pattern when adjusting

headlights on some vehicles. Canbuilt has developed a beam elucidation filter to make it easier

to view these beam patterns. The filters are designed to remove some of the extraneous light

from the viewable pattern and enhance the high intensity zone, providing an image that is

clearer and easier to see.

To use the filter, simply set it on top of the aimer body above the viewing window. The magnetic

strips will hold it in place. For best operation, the magnetic strips should be toward the front and

rear of the aimer. Choose the filter (or filters) that works best for your vision.

The filters can be stored by using the magnetic strips to attach them any place on the metal

aimer head.

BEAM ELUCIDATION FILTERS

Place filter over viewingPlace filter over viewing

window herewindow here

Place filter over viewing

window here

Page 7 - Aiming Procedures

Canbuilt Mfg.

Perfect Night Vision.....