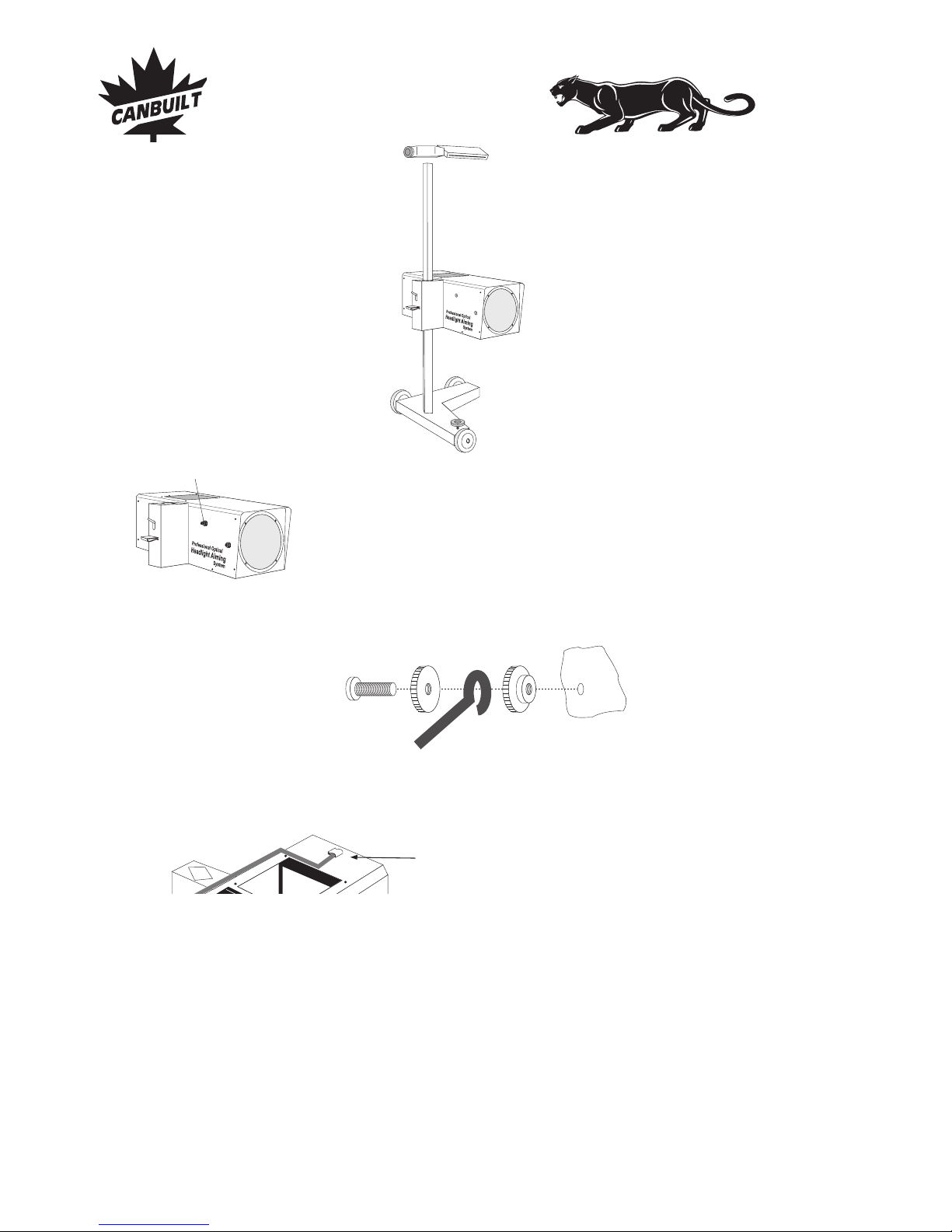

Calibrating the Floor

0

9

8

7

6

5

4

3

2

1

Floor slope adjustment knob

Fig. 19

RECORDING THE FLOOR SLOPE SETTING

Near the floor slope adjustment knob , there is a

register consisting of a small cylinder that can be

used to count the turns of the knob . This register

sinks or raises with each turn of the knob (fig. 19).

Shops using the aimer in more than one location

should record the floor slope settings for each

location.

.

Use the recorded floor slope setting for subsequent

uses in the same location. Simply set the slope

adjustment knob to the previously recorded position

prior to aiming headlights.

ONCE THE SETTING IS RECORDED, IT IS NOT

NECESSARY TO TAKE THE FLOOR SLOPE

MEASUREMENT AGAIN FOR THIS LOCATION

Note: A decal is included with the aimer. You can record floor slope settings and adhere

the decal to aimer for reference. You can also use the matrix below for recording this

information.

BAY NUMBER REGISTER SETTING

REGISTER SETTING KNOB SETTINGKNOB SETTING DATE

Page 8 - Floor slope register

Canbuilt Mfg. Perfect Night Vision.....