EN

L-L 265.00-BM 7 / 24

IMPORTANT

Before using the space heater, carefully read all of the instructions and follow them scrupulously. The manufacturer cannot be

held responsible for damage to persons and/or property caused by improper use of the equipment.

This instruction manual is an integral part of the equipment and must therefore be stored carefully and passed on with the unit in

the event of a change of ownership.

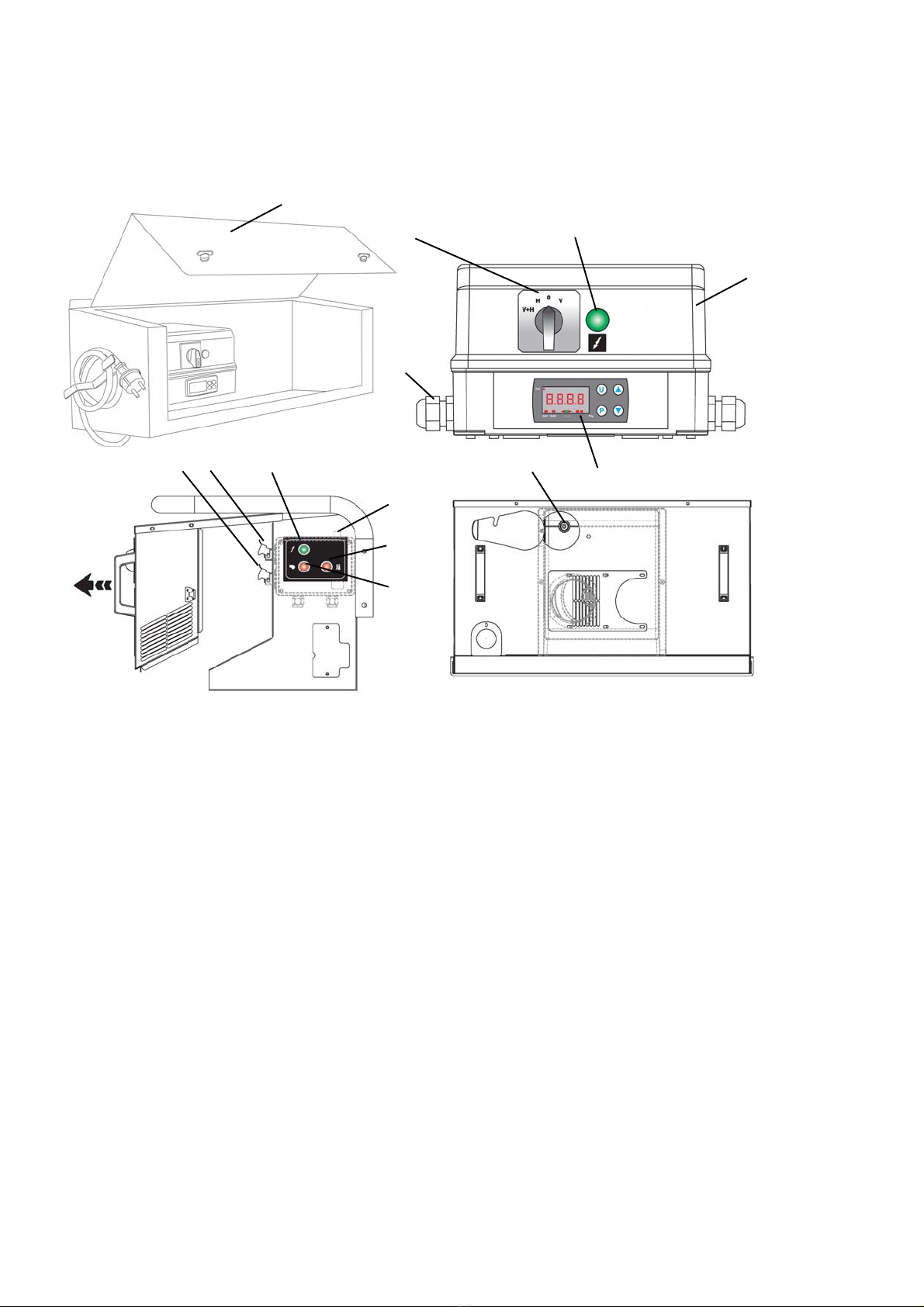

1. DESCRIPTION

Space heaters described in this manual, are designed for use in

medium to large-sized rooms and buildings where a fixed or mobile

heating system is required.

The air required for combustion is sucked directly by the burner (6)

installed on the heater, and can be supplied:

• from the outside by using the flexible connection tube (available

as an accessory), which avoids consuming oxygen in the room to

be heated, or

• from inside the room to be heated. In this case, the room must be

well ventilated to guarantee sufficient exchange of air.

The flow of hot air is moved by the high-efficiency fan (4): air is

heated by the thermal energy generated during la combustion and

heat from the smoke is transmitted to the fresh air through the

metal walls of the sealed combustion chamber and the heat

exchanger. After the combustion products are cooled, they are

conveyed to a discharge duct and eliminated through a chimney or

flue large enough to guarantee their removal.

The space heaters can work with burners having ON-OFF work

modes and fuelled by natural gas or propane.

Warning

Only burners approved by the manufacturer and listed in

the “TECHNICAL SPECIFICATION TABLE” can be used.

The heater’s certification and warranty will lapse if the

burner is replaced with a non-original model, even if it has

similar specifications.

All of the space heaters are fit with an electronic device that

controls the flame and with:

• safety devices (safety thermostat with manual reset, flame

control, air pressure switch) that trip in case of serious

malfunctions and cause a safety stop. In this case the heater

stops, button (d) lights with a steady red light (Stop Light) and the

heater can resume operation only after the cause of the stop has

been identified and eliminated;

• control devices (temperature controller to control temperature of

air outflow, complete with hour counter, fan thermostat, burner

thermostat, voltage control) that trip in case of minor operating

faults or supply faults, causing temporary stop of the space

heater. In this case, the heater will restart automatically when the

required condition is restored.

The section “TROUBLESHOOTING” describes all possible operating

faults and their possible remedies.

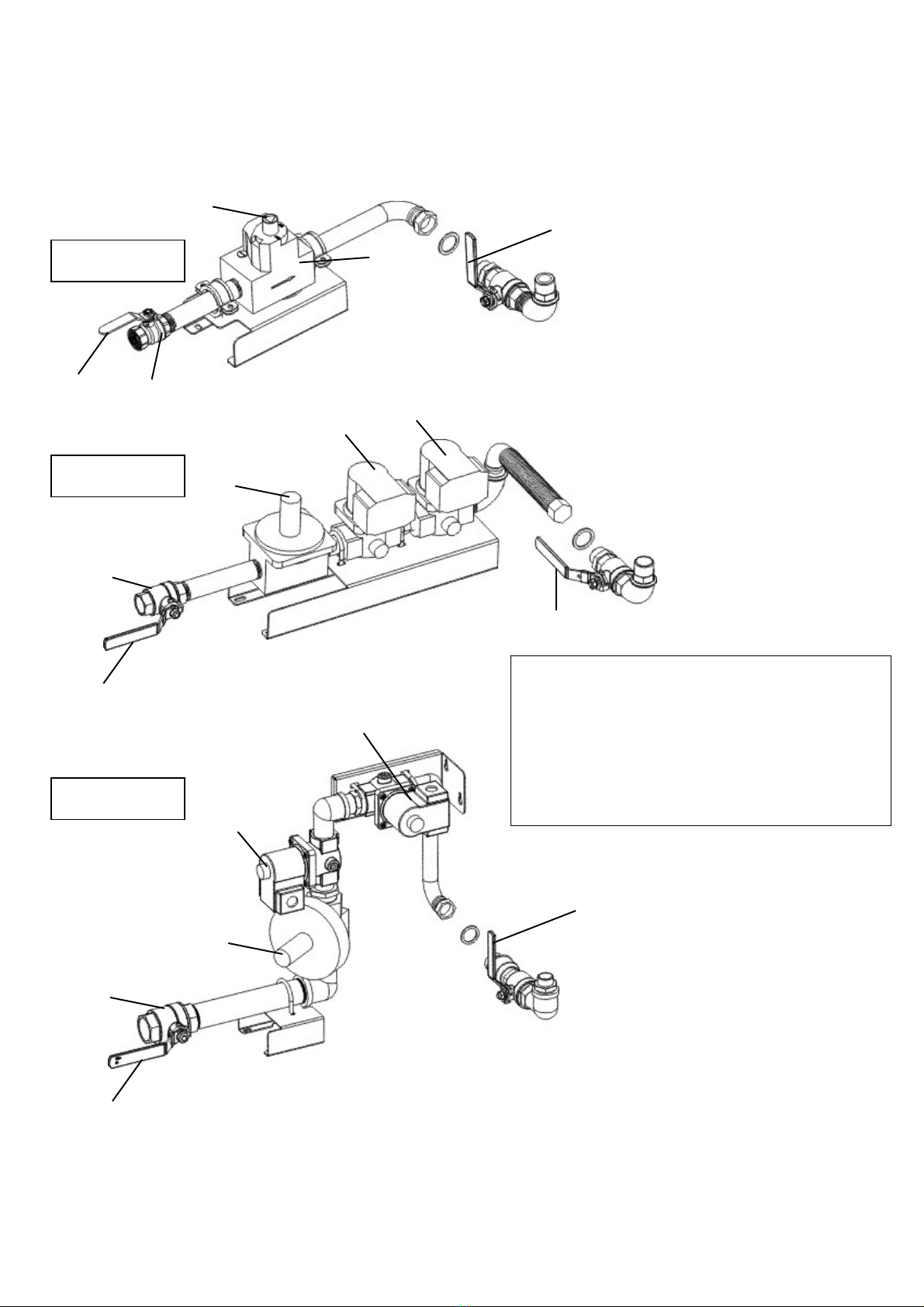

2. CONDITIONS OF SUPPLY

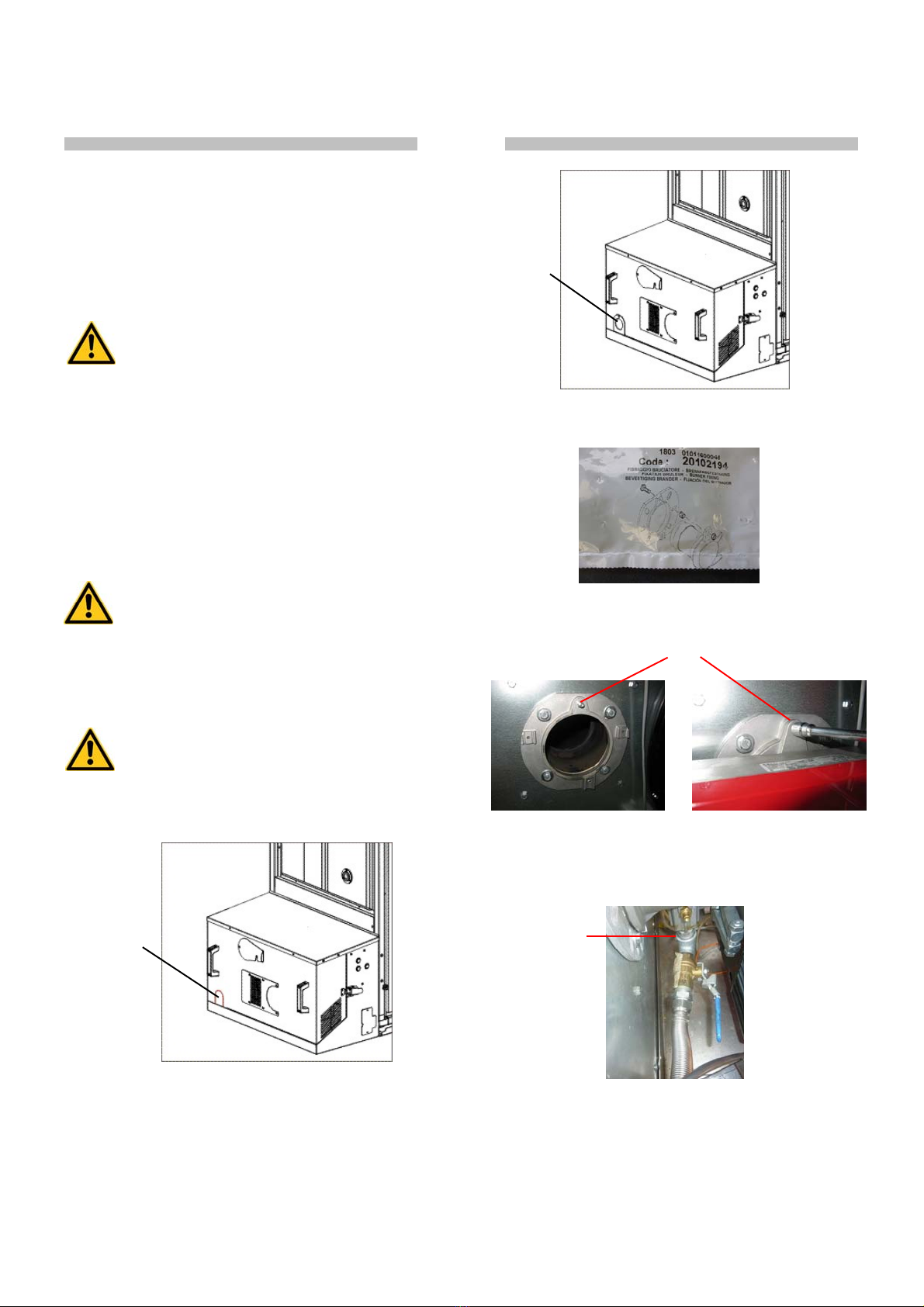

The heater is delivered with parts to be assembled and set as

described in chapter 4.

• Heater body

• Burner

• Air distribution connector

• Any required accessories (flue pipes, air distribution pipes, etc.)

Warning

Prior to installation, burner adjustment and ignition, the

space heater should be assembled in full.

All assembly operations should only be performed by

professionally qualified personnel only.

The following are also supplied:

• use and maintenance manuals for

• space heater

• burner

• manuals with drawings and spare part lists:

• space heater

• burner

Warning

All documents provided constitute an integral part of the

unit.

The documents should therefore be looked after with care

and supplied with the unit in the event of a change in

ownership.

Parts are to be transported and moved using either a manual or

automatic forklift truck with sufficient load capacity.

Warning

Never try to lift the heater manually. Doing so could cause

serious physical injury.

3. GENERAL ADVICE

The space heater must be installed, adjusted, and used in

conformity to national and local laws and regulations for its

operation.

General guidelines:

• Follow the instructions in this booklet very carefully;

• The heater is not installed in an area where there is a high risk of

fire or explosions;

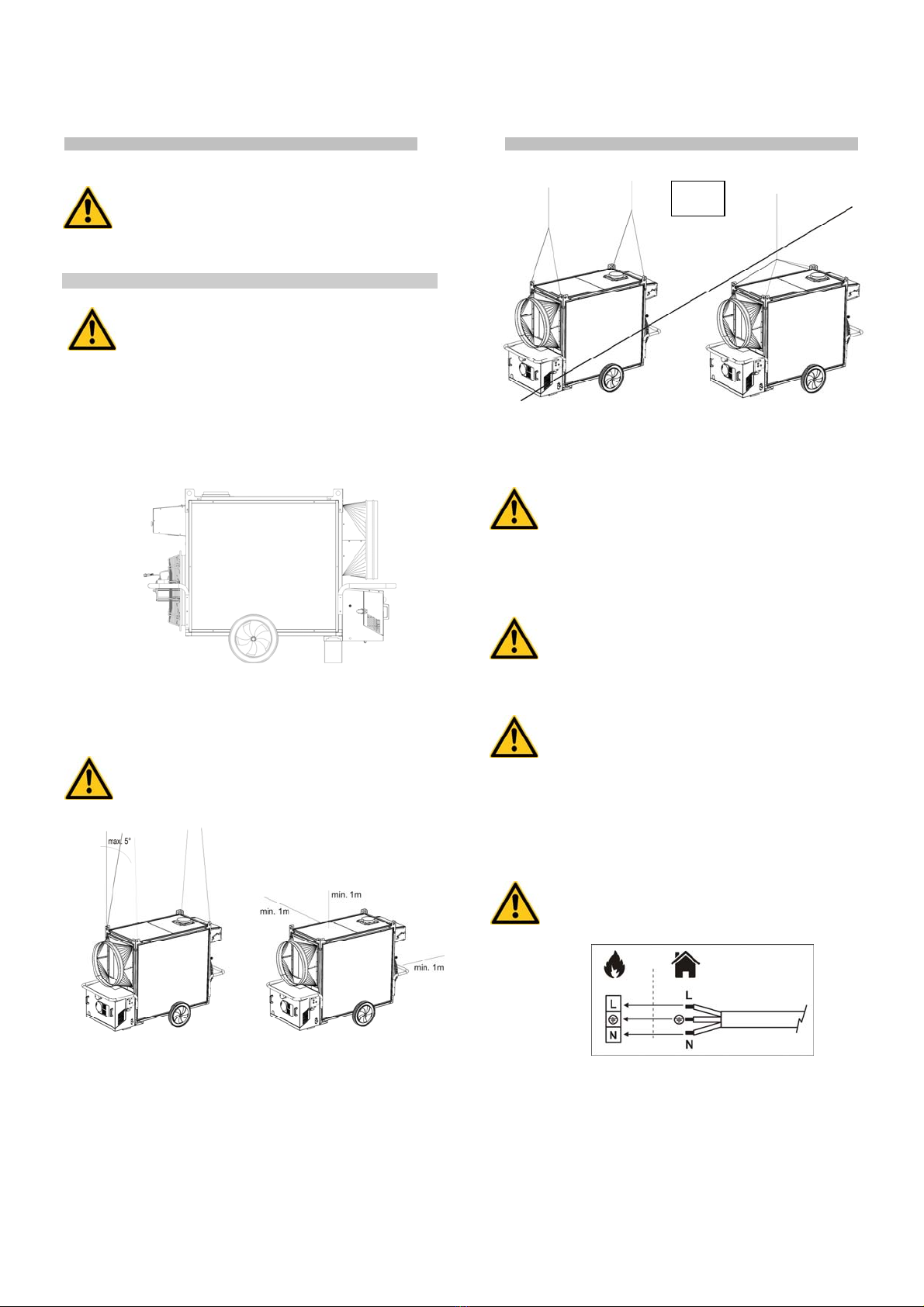

• Minimum clearances from combustible material must be:

1 m (3 feet) from side and rear (air inlet) of heater

1 m(3 feet) on top of heater

3 m (10 feet) on air outlet of heater.

• Keep inflammable material at a safe distance from the heater

(minimum 3 metres);

• Check that there is no overheating of walls, ceilings or floors made

of inflammable materials,

• All precautions have been taken to prevent fires;

• The room being heated must be sufficiently ventilated so that the

heater has enough air to function properly;

• The heater must be near a chimney or chimney flue and an

electrical panel conforming to declared specifications;

• Check the heater before switching it on and at regular intervals

during its use;

• After use, make sure the disconnecting switch is off.

When using any type of space heater it is obligatory:

• not to exceed the maximum heat output level of the furnace

(“TECHNICAL SPECIFICATION TABLE”);

• make sure that the air flow is not below the rated level; check that

there are no obstacles or obstructions to the air suction and/or

delivery ducts, such as sheets or covers on the equipment, walls

or large objects near the heater.