produce pure air ;ince they are equipped wlth a chimney connec-

GENERAT VMENDATIONS

ale to be run on heating with light diesel oil. GE

air mixed with combustion 0ases, EC heaters

bustion gases outside via a flue.

ordinances and codes when using this heater:

ti( hting equipment is readily available;

ient fresh outside air is provided according t0

;ments. GE heaters should only be used in well

not start, check that oil tank is full and depress

rr still not work, please refer to chapter "08'

ISES AND REMEDIES".

HEATER

(3) on "0" position or turn thermostat or othel

rst sening.

5

with an electronic tlame control box. In case ol

wilt cut in and stop the heater, at the same time

Before heater is moved it must be stopped and unpluooed. Before

moving the heater wait till it has tohlly cooled olf and make sure oil

tank cap is securely fixed.

GE - EC heaters with wheels must be wheeled. The suspended ver-

sion which has no wheels must be lransported with adequate machinery'

MAINTENANCE

Preventive and regular maintenance will ensure a long trouble lree

lite to your heater.

Warning llever service heabr while it is plugged in, openting or hoL

severe buns ot electrical shock Gan ocDur.

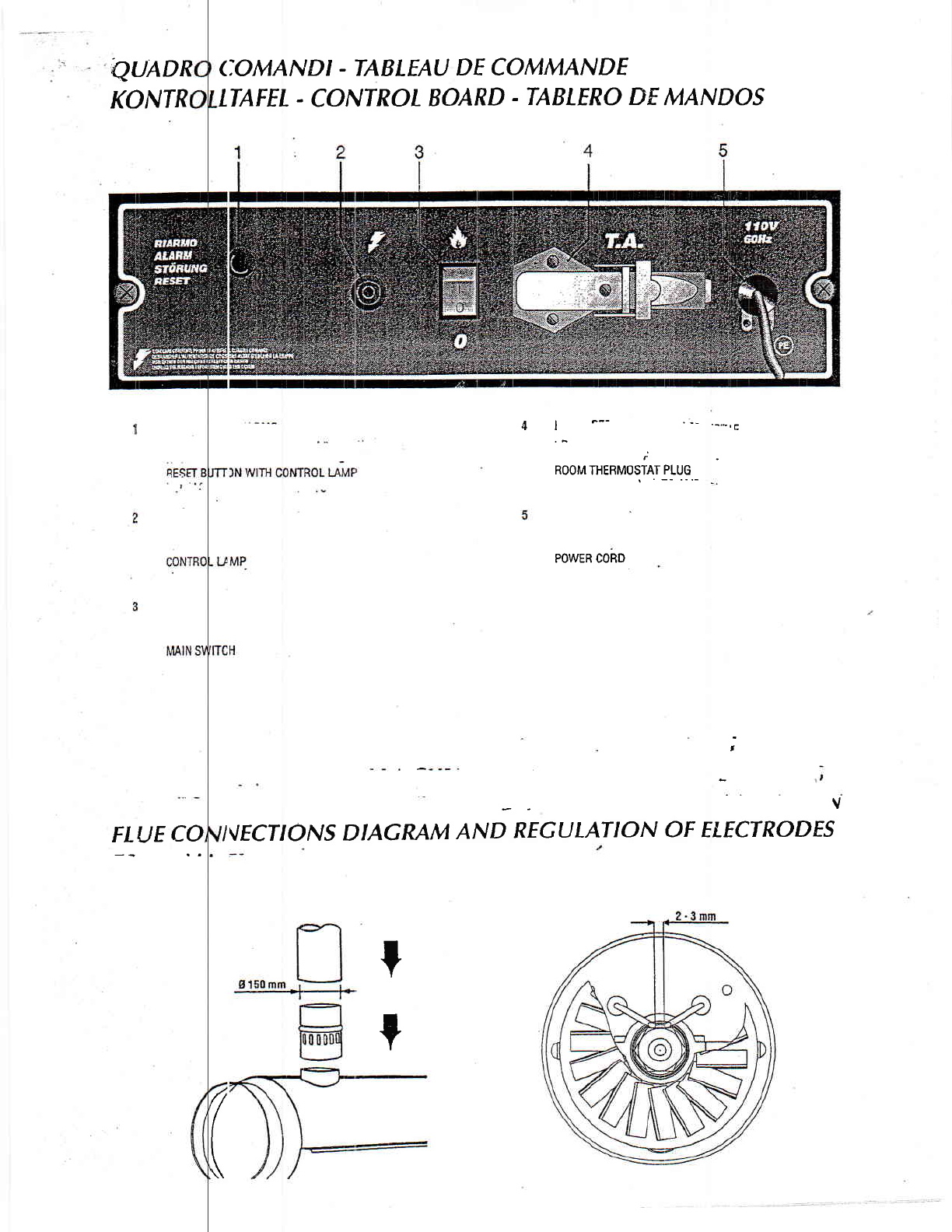

Every 50 hours of operatlon: disassemble lilter and wash with

clean oil, remove upper body parts and clean inside and ventilator with

compressed air, check correct attachment of H.T. connectors t0 the

eleclrodes and check H.T. cables, remove burner assembly' clean and

check electrode settings, adiust according to scheme "REGUI-AT|0N

OF ELECTRODES".

GE and EC

heaters produce

tion to canalise the

Awalffo-ttow

. Make sure

. Make sure

the heater

and animals

. Unpluo

cedure once or

Should the

reset button (1)'

Should the

SERVED FAUL

STOPPING

Set main

control device on

SAFETY

The unit is

malfunction this

the pilot lamP in

Heaters are

trol box before

. Read and lhis owneis maflual before usino the heaten

. Use only in I free of flammable \apours or high dust contenq

in immediate proximity of flammable materials.

. Never use

Minimum ce 2"50 m;

vented order to avoid carbon monoxide poisoning;

ir tet (reaQ or air outlet (front);

. Never block

. ln case ol low temDeratures add kerosene to the heating oil;

, Make sure 'is atways under surveillance and keep children

I from it:

. Before tl e heater dways check free rotation of ventilator;

wlren not in use.

Warning

OPERATION

Before anY I of starting the heater is made, check that your

ms to the data on the model Plate.

t be fitted with a thermo'magnetic differeF

nust be linted to a sockel with a mains

electrical suPPlY

The heater ru r automatically when connected to a control de-

vice such as

connectors 2 and rsllt, time clock. Connection of control is made at

ol the plug (2) fitted to the heater after having re'

moved the be ween 2 and 3 as fitted ex works. This bridge

ret'ofitted if manual running of heater is whished at

should be kept

an0ther time.

To start , cc nnect to mains, set control device at desired val-

ue, set switch (3)

lowed by ignition. trosition 6: the ventilator starts, immediately fol-

n unit is started tor the first time or is started al-

ter the oil tank b( en totally emptied, the flow 0f oil to the burner

a r in the circuil ln this case the control box will

may be irnPaired

cut out the heatet it might be necessary to renew the starting pro-

t y depressing the reset button (1 )'

Mains

tial su

Unit r

crntrol box resel button (1) will light up-

equipped with an overheat thermostat safety cut

out which will tlre heater in case of overheating. This thermostal

will reset y butyou will have to depress button (1) 0n con'

lble to restart the heater.

TRANSPOR

aking any attempt to restart heater find and

reason ol ovelheating.

Warning Bel