Canusa warrants that the product conforms

to its chemical and physical description

and is appropriate for the use stated on the

installation guide when used in compliance

with Canusa’s written instructions. Since

many installation factors are beyond

our control, the user shall determine the

suitability of the products for the intended

use and assume all risks and liabilities in

connection therewith. Canusa’s liability is

stated in the standard terms and conditions

of sale. Canusa makes no other warranty

either expressed or implied. All information

contained in this installation guide is to be

used as a guide and is subject to change

without notice. This installation guide

supersedes all previous installation guides

on this product. E&OE

Canusa-CPS

A division of Shawcor Ltd.

Head Office

25 Bethridge Road

Toronto, ON, Canada M9W 1M7

Tel: +1 416 743 7111

Fax: +1 416 743 5927

Canada

Dome Tower St. 2200,

333-7th Avenue SW

Calgary, AB, Canada T2P 2Z1

Tel: +1 403 218 8207

Fax: +1 403 264 3649

Americas

5875 N. Sam Houston Pkwy W.,

Suite 200

Houston, TX, USA 77086

Tel: +1 281 886 2350

Fax: +1 281 886 2353

Middle East

ADPC - Mussafah Port,

P.O. Box 2621

Abu Dhabi, UAE

Tel: +971 2 496 3500

Fax: +971 2 496 3501

Europe, Africa & Russia

Dellaertweg 9-E, Gebouw

“Le Carrefour”

2316 WZ Leiden,

The Netherlands (NL)

Tel: +31 71 80 802 70

Fax: +31 71 80 802 71

Asia-Pacific

101 Thomson Road,

#11-03 United Square

307591 Singapore

Tel: +65 6749 8918

Fax: +65 6749 8919

Quality Management system

registered to ISO 9001

Part No. 99060-262

IG_Atomizer_rev015

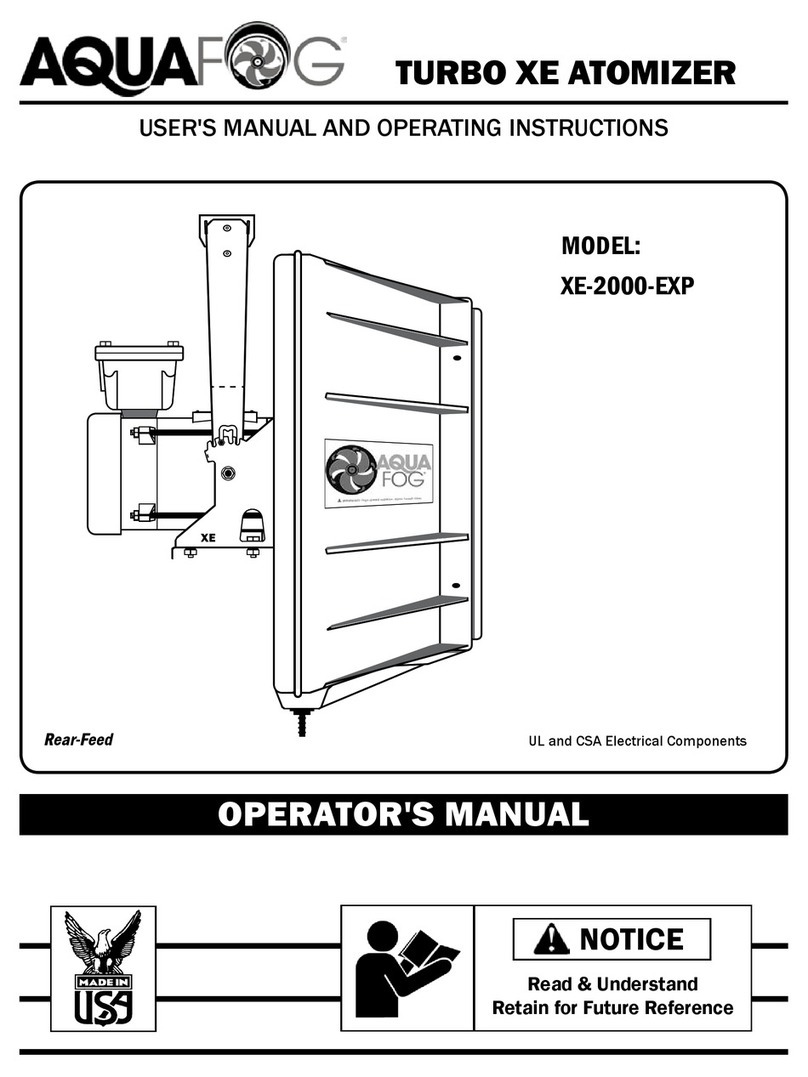

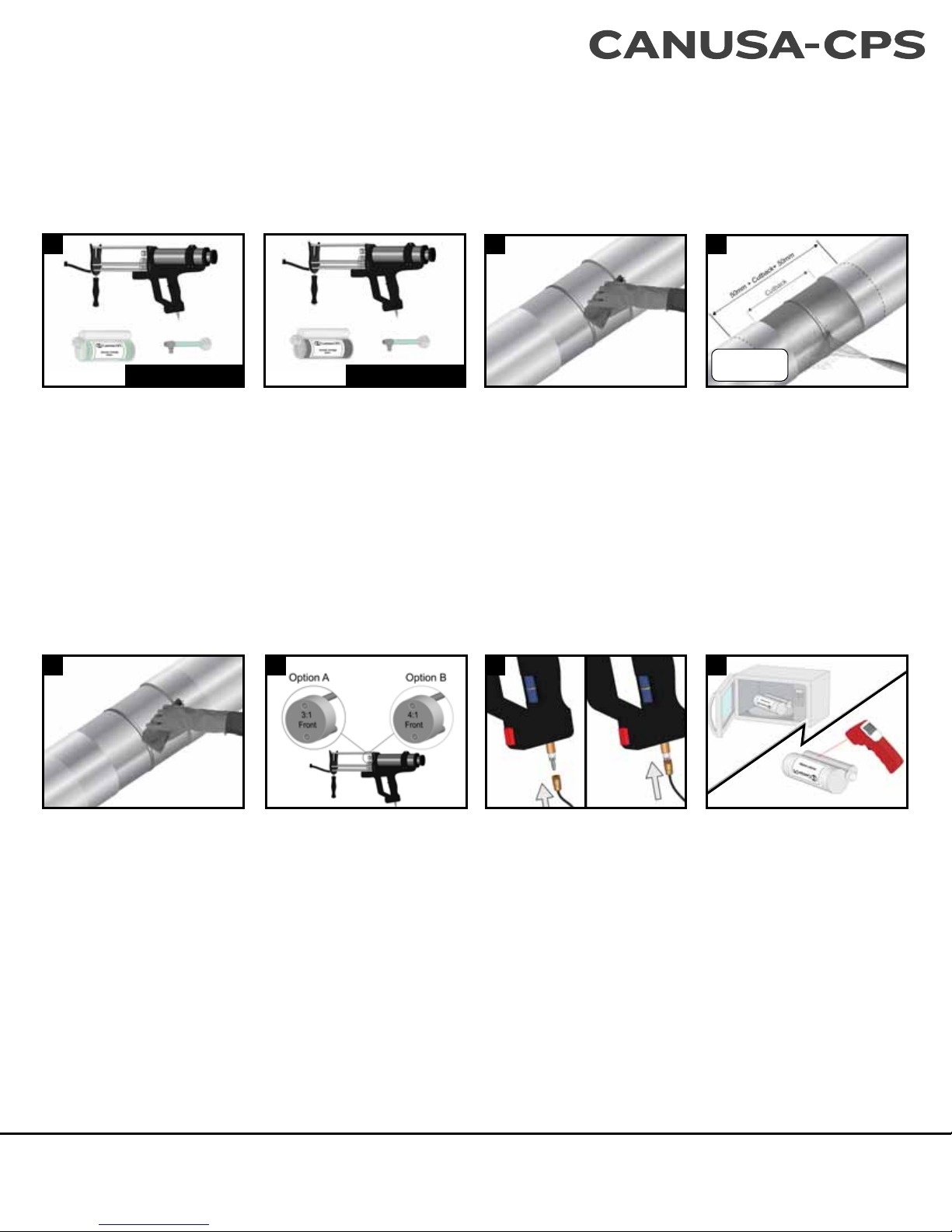

Adjust the atomizing air pressure dial

to #3 +/- 1. This setting may vary

depending on the temperature of the

product and input air pressure.

Note: When spraying with a right-angled

mixing tip, increased air pressure may be

required.

12

11

Adjust the fluid control dial to a setting

of #3 +/- 1 by scrolling up or down. The

dial is located on the side of the gun

handle, behind the trigger. This setting

regulates the speed/pressure of the two

pistons. This setting mayvary depending

on temperature of product and input air

supply pressure.

Adjust Fluid Control Dial Adjust Air Pressure Dial

10

Slide the cartridge into the Atomizer gun

with the Base side of the cartridge (large

end) down first. The two ejector plates

of the gun should match the piston seal

area of the cartridge. Once the cartridge

is placed securely into the gun chamber,

attach the quick lock air hose to the

mixing tip nozzle end by ‘snapping’ it in

place.

Insert Cartridge &

Attach Air Connector

Install Mixing Tip

9

Hold the cartridge with end cap fac-

ing up. Remove the cartridge end cap

by unscrewing (counter-clockwise) and

pulling up. Fit the mixing tip end over

the cartridge outlet and screw the mix-

ing tip cap to securely lock the cartridge

and mixing tip together. Mixing tips are

intended for one time use only.

Lightly Shake Cartridge

8

Once heated, the viscosity of the cure

side will be very low. Holding the base

side of the cartridge, shake the cartridge

up and down and side to side to lightly

redistribute the pigment colour in the

cure side of the cartridge.

Storage & Safety Guidelines

To ensure maximum performance, store

Canusa products in a dry, ventilated area.

Keep products sealed in original cartons

and avoid exposure to direct sunlight, rain,

snow, dust or other adverse environmental

elements. Avoid prolonged storage at

temperatures above 40°C (104°F) or

below 5°C (41°F). Product installation

should be done in accordance with local

health and safety regulations.

Appropriate PPE should be worn in compli-

ance with the requirements of the material

Safety Data Sheet and local health and

safety regulations and should include the

use of a full face shield.

These installation instructions are

intended as a guide for standard products.

Consult your Canusa

representative for specific projects or

unique applications.

Purge cartridge and mixing tip nozzle

by pulling the trigger long enough to

just fill the static mixing tip chamber

with material. The Atomizer Gun is now

ready for spraying. Release trigger half-

way to stop the fluid ejector pistons.

Release the trigger completely to stop

the atomizing air (stop spraying) or when

cartridge is empty.

13

Purge Cartridge

& Spray Surface

14

Press the red button to retreat fluid

ejector pistons. Remove atomizing

air hose from mixing tip and remove

cartridge.

Remove Used Cartridges