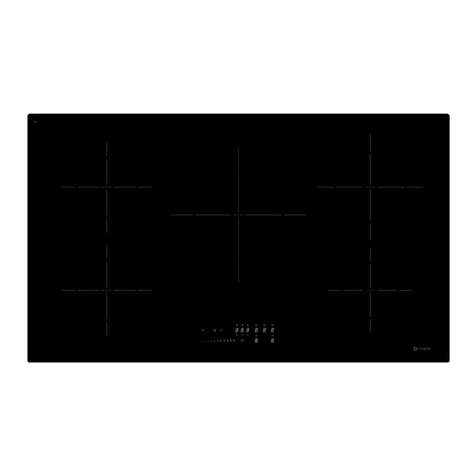

PROCEDURE OF CONFIGURATION (E4) - TC SMART SLIDER

A. Disconnect the hob from the electrical network.

B. Connect the network and take into account that the configuration setting has to be made in a

maximum time of 2 minutes (If the time goes over, the procedure must be begun again from

stage A).

C. Do not switch on the hob by pressing key [ ].

D. Press and keep the finger on key [ ] until you hear a “Beep”.

E. Then, press on each display in the order « A-B-C-D-E-F » until you hear a “Beep”.

F. Remove your fingers from the touch control, then push again on touch [ ] during few

seconds, until blinking [ E ] symbols appears.

G. Wait until [ E ] symbols stop blinking. After few seconds, [ E ] are automatically

transformed in [ C ]. The existing setup has been cancelled

H. Take a ferromagnetical pot with a minimum diameter of 16 cm. Select a cooking zone by

pushing on the corresponding [ C ] display. Place the pot on the area to be set. Wait until

the [ C ] display becomes a [ - ]. The selected cooking zone is now configured.

I. Follow the same procedure for each cooking zone with a [ C ] display.

All the cooking zones are configured once all the displays are turned off.

Please use the same pot for the whole procedure.

Never put several pots together on the zones during the setup-process.

The hob is now ready to be used.

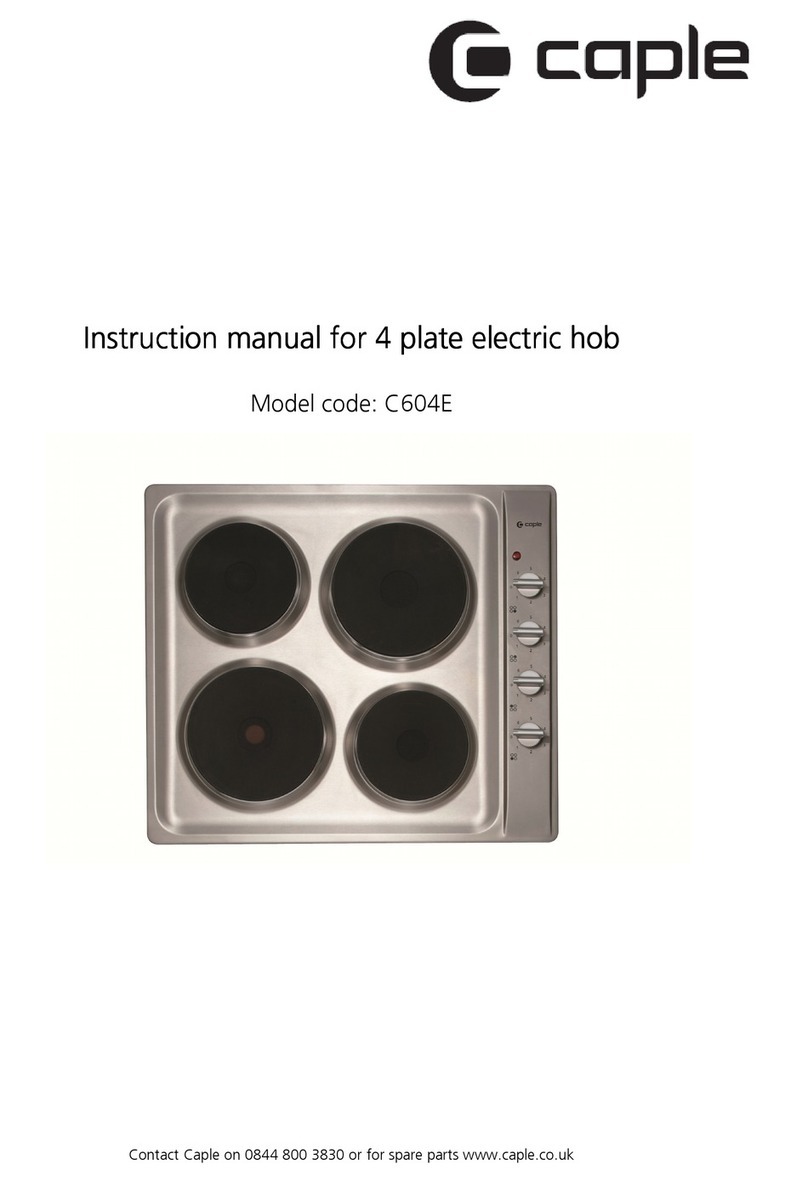

Caple C901I Induction Hob