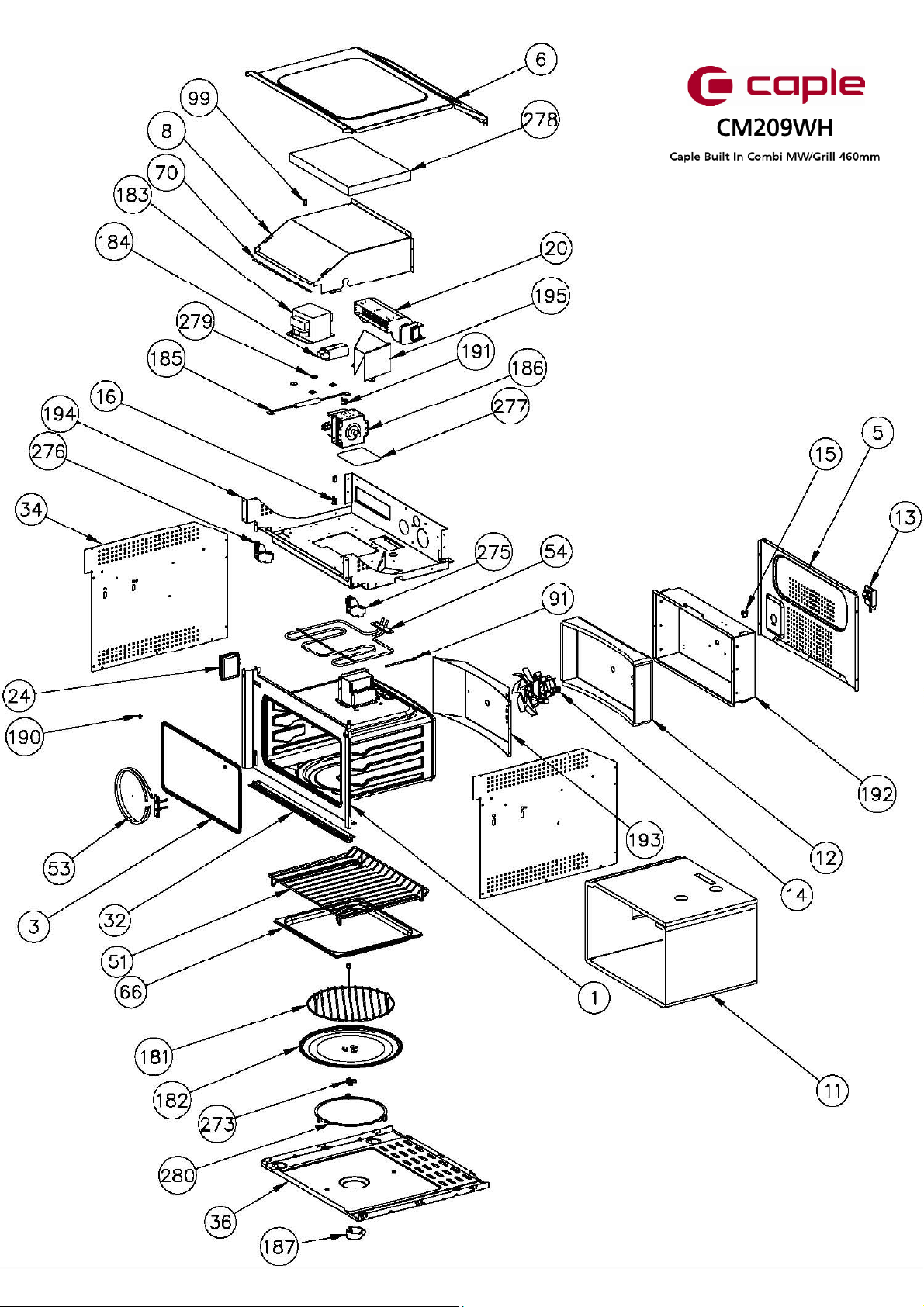

Item Part Code Description

142703120 MUFFLE

3a 12381850 MUFFLE GASKET (until 23/03/14)

3b 12382130 MUFFLE GASKET (from 24/03/14)

512111260 BACK SHIELD

612111170 TOP SHIELD

812111860 AIR CONVEYOR F45N µONDE

11 12381530 FIBERGLASS SHELL

12 12380980 FIBERGLASS REAR

13 12530000 TERMINAL BLOCK/FASTEN CABLE 16A

14 12590191 RADIAL FAN

15 12540943 SAFETY THERMOSTAT PRESET T165¢C

16 12540944 SAFETY THERMOSTAT PRESET T110¢C

20a 12590150 TANGENTIAL COOLING FAN (until 10/07/14)

20b 12590270 TANGENTIAL COOLING FAN (from 11/07/14)

24 12540960 HALOGEN RECTANGULAR LAMP SOCKET 25W 230/240V

CM209WH

- Caple built in microwave

32 12192671 LOWER PROFILE F45N STEAM BLACK

33 12112541 COUNTER FRONTAL

34 12112400 LEFT-RIGHT SIDE SHIELD

36 12111810 BOTTOM SHIELD

51 12200460 SHELF

53 12570170 CIRCULAR HEATING ELEMENT 1500W

54 12570180 GRILL HEATING ELEMENT 1500W

66 12105390 TRAY H20 INOX GN2/3 F45N

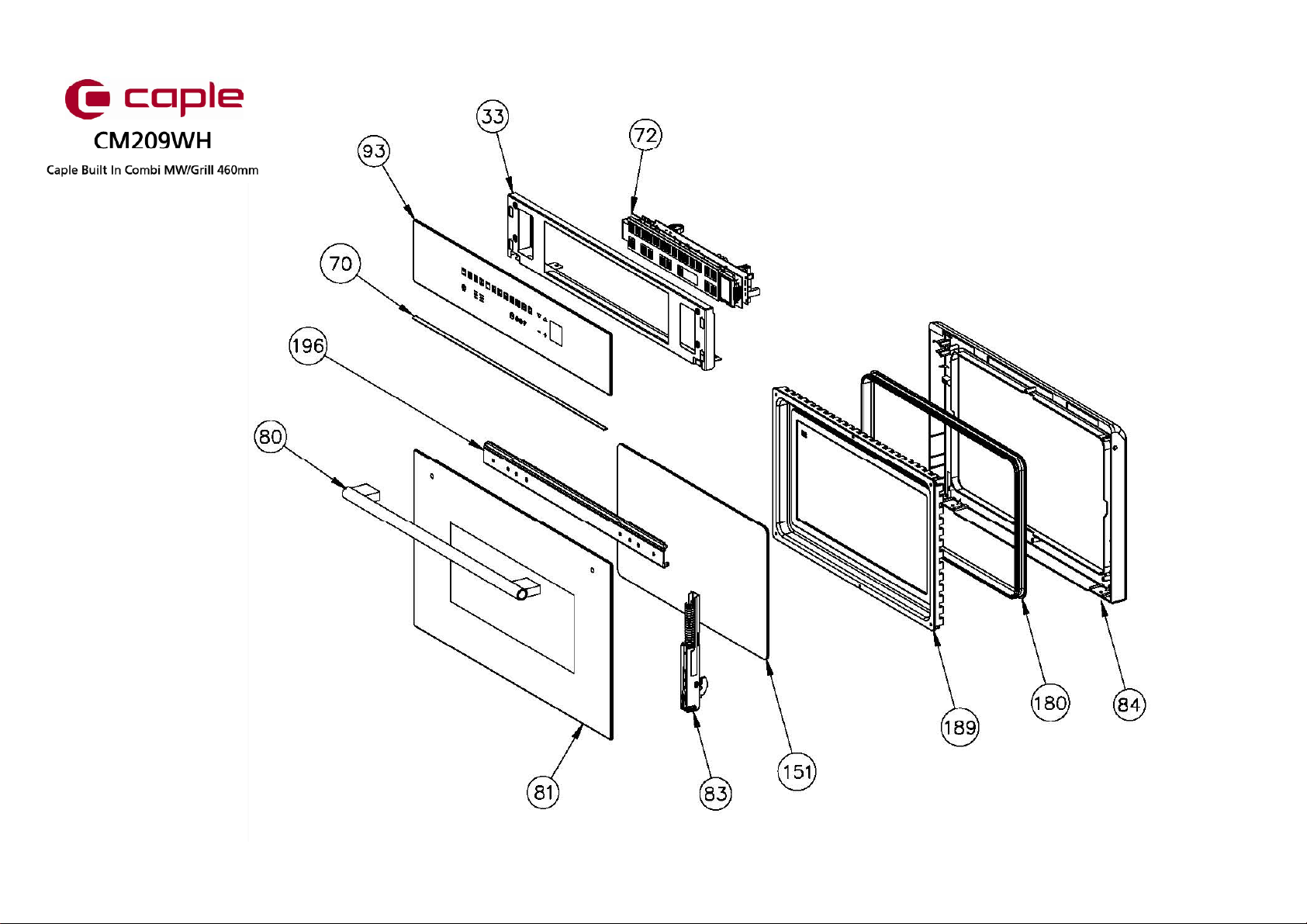

70 12380950 ADHESIVE GASKET

72 42782041 INTERACTIVE POWER BOARD MICROWAVE 11F µF45N W/COOKBOOK

80 12740600 HANDLE SENSEHAN1 MAURICE LAY

81 42713330 GLASS DOOR

83 12600280 DOOR HINGE

84 12301000 INNER DOOR

91a 12541190 NTC PROBE (until 26/07/15)

91b 12542090 NTC PROBE (from 27/07/15)

93 42715689 FRONTAL GLASS

99 12380500 RUBBER FOOT FOR HINGE

151 12323500 3rd INNER GLASS THERMO REFLECTIVE

180 12381000 DOOR GASKET

181a 12702000 ROUND SHELF H75 (until 06/10/13)

181b 42702000 ROUND SHELF H75 (from 07/10/13)

182 12380930 FLAT GLASS SWIVEL

183 12541110 TRANSFORMER

184 12541120 CAPACITOR 2100Vac 50/60Hz 1.05µF

185 12541130 FUSE CARRIER + FUSE 0.8A-5kV

186 12570160 MAGNETRON

187 12590140 GEARMOTOR

µ