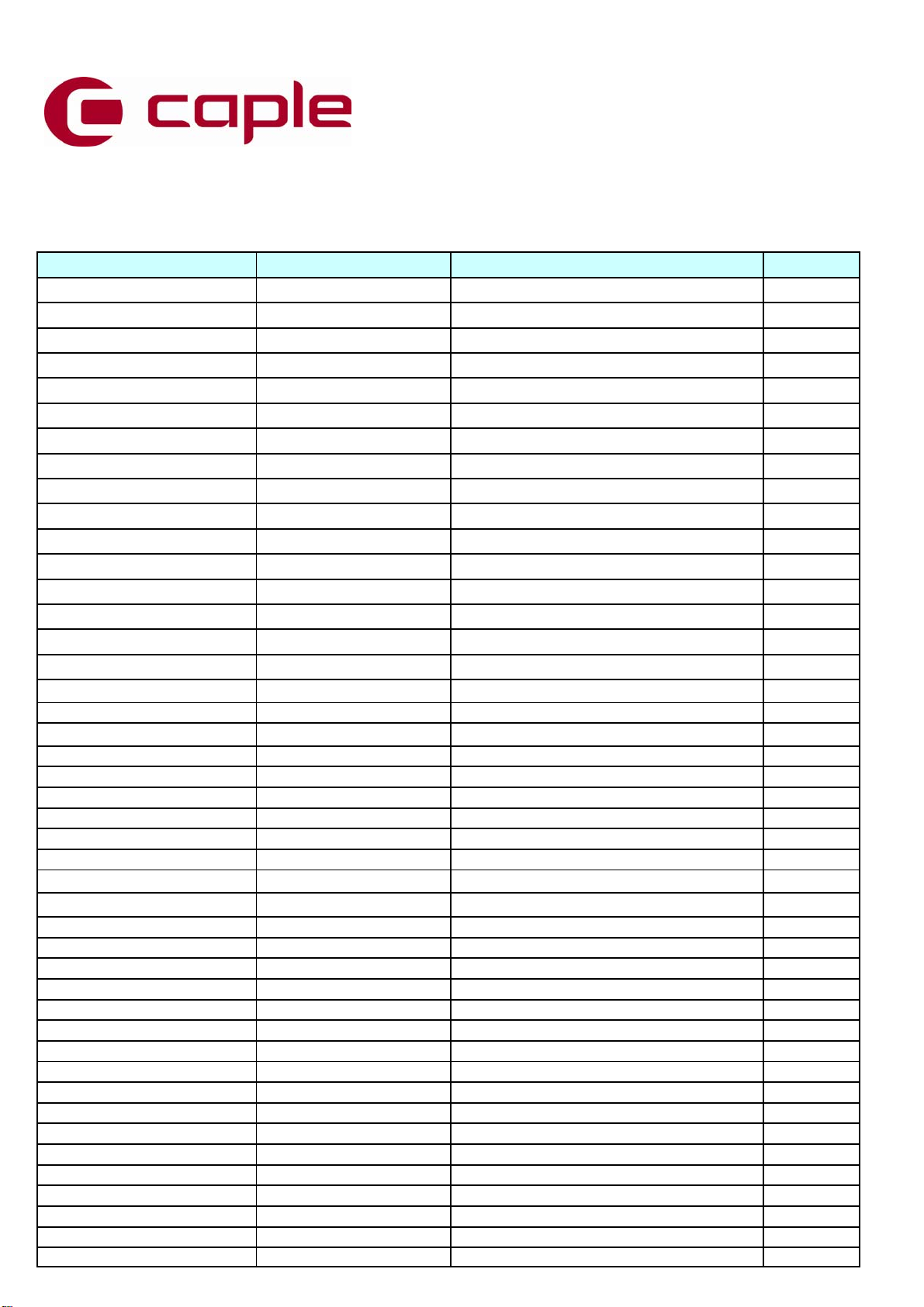

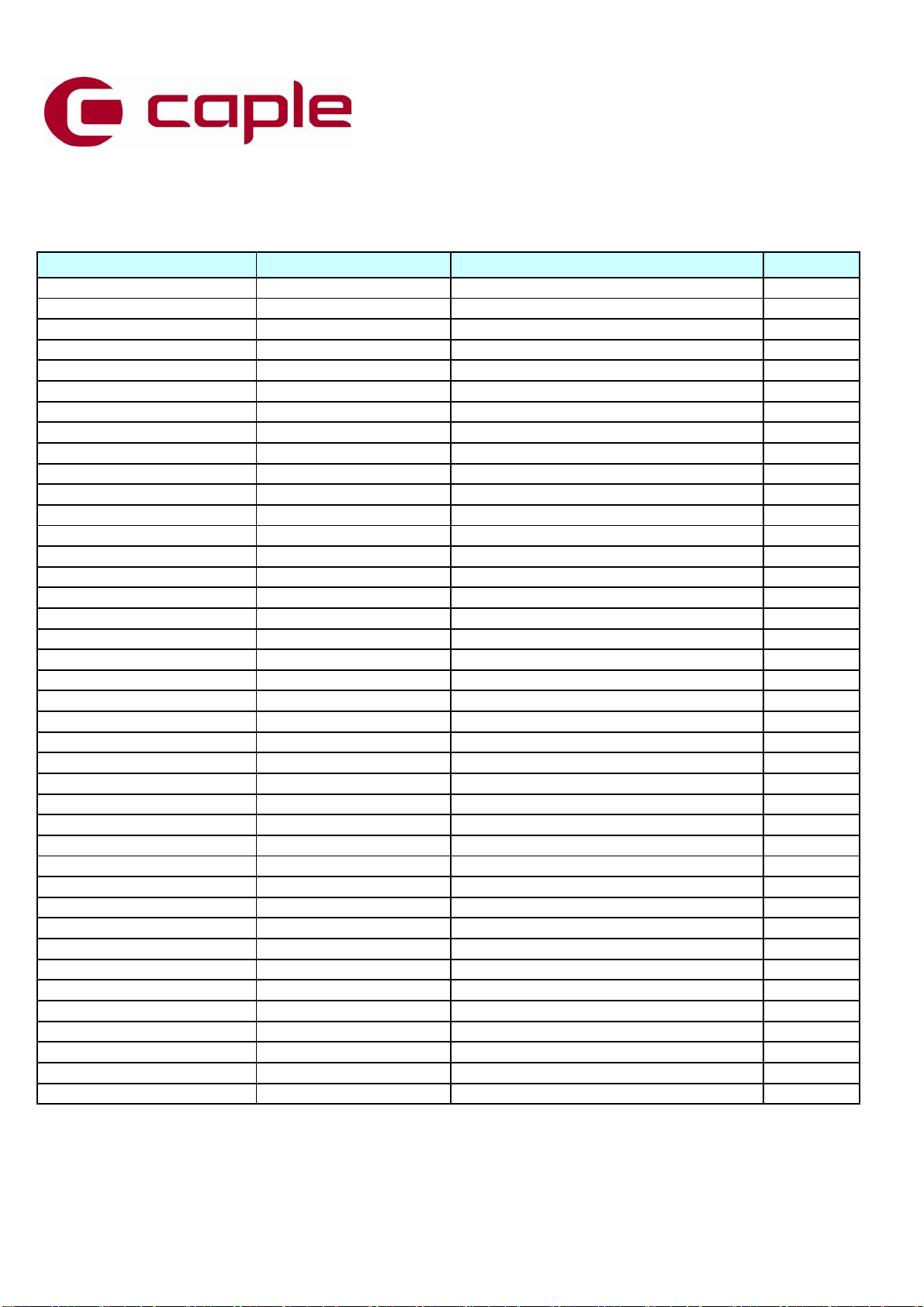

Item Part Code Description Qty

011300410000018 RING 2

012171100000295 Handle 2

A00 12270000004942 ASS'Y CAVITY 1

A01 12570000000067 SPLASH COVER 1

A16/A13 12270000008244 THERMOSTAT BRKT. 1

A17 12270000005573 ASS'Y BRKT HINGE 2

B01 12270000009910 BASE PLATE 1

C00 17270000000313 ASS'Y CONTROL 1

D00 12270000007448 ASS'Y DOOR 1

E01 17470000000806 MAGNETRON 1

E05 17470000003445 H.V.TRANSFORMER 1

E06 17470000000689 H.V.CAPACITOR 1

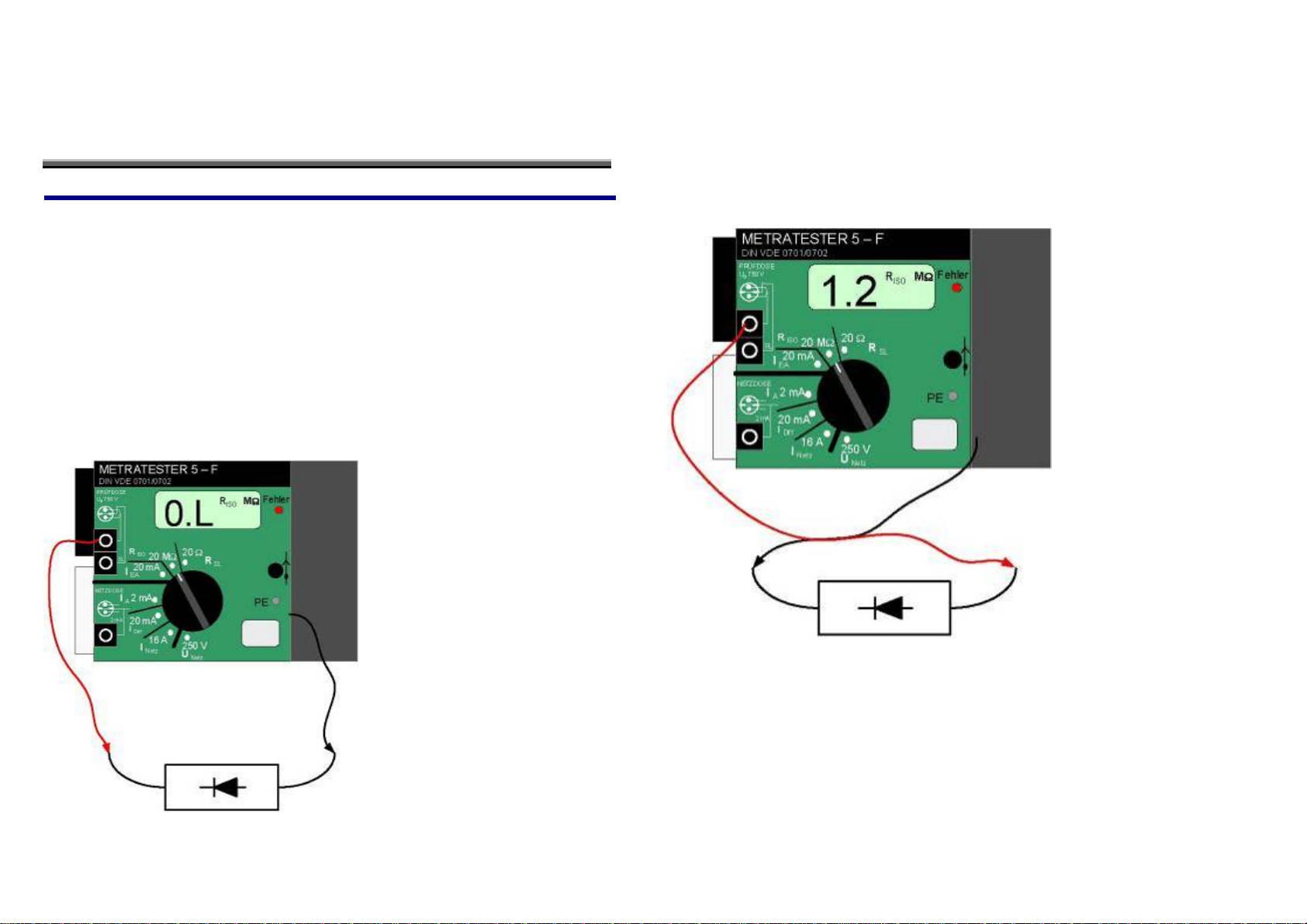

E07 17470000001007 H.V.DIODE 1

E10+E11 17170000002914 ASS'Y NOISE FILTER 1

E13 17470000000636 LAMP 1

CM140

- Caple Built in Microwave

E14 12270000000200 LAMP COVER 1

E16 17470000000062 POWER CORD 1

E26 11201007000351 TEMPERATURE SENSOR 1

E28/34T,E08 17470000001561 H.V.FUSE 1

E34 17470000001471 THERMOSTAT 180/145Ԩ*H 1

E37 17470000001487 THERMOSTAT 150/90Ԩ*V 1

E48 17470000001483 THERMOSTAT 100/80Ԩ*H 1

G03 17470000001053 METAL HEATER *UPPER 1

G09 12270000006265 HEAT INSULATOR *UPPER 1

G10(36F)12270000003490 Heater holder 2

G10/E50 17470000001085 HEATER *LOWER 1

L03/L12 17470000002315 MICROSWITCH INTERLOCK 1

L03/L12 17470000002315 MICROSWITCH INTERLOCK 2

L04 17470000002299 MICROSWITCH MONITOR 1

L05 17470000001353 #N/A 1

L09 12170000011191 LATCH BOARD *LEFT 1

L10 12170000011190 LATCH BOARD *RIGHT 1

L11 12170000007317 INTERLOCK LEVER 1

L13 17470000001212 HARNESS MAIN -2 1

L14 17470000001462 HARNESS MAIN -3 1

R00 12270000005274 Convection ASS'Y 1

R01 11002017000370 Motor Conv. 1

R02 12270000004607 CONVECTION MOTOR BRKT. 1

R03 12270000005062 COOLING FAN(CONV.) 1

R04 12270000006226 HEAT INSULATOR *Inner 1

R05 12270000006356 BACK HEATER COVER 1

R06 17470000001081 METAL HEATER *Back 1

R08 12270000005066 CONV. FAN 1