be suitable for the load required and it must comply with

current legislation.

• If the hob is electric, gas, or induction, the minimum

distance between the same and the lower part of the hood

must be at least 45 cm. If a connection tube composed of

two parts is used, the upper part must be placed outside the

lower part. Do not connect the cooker hood exhaust to the

same conductor used to circulate hot air or for evacuating

fumes from other appliances generated by other than an

electrical source.

- In the case of assembly of the appliance in the ducted

version prepare the hole for evacuation of the air.

• We recommend the use of an air exhaust tube which

has the same diameter as the air exhaust outlet hole. If a

pipe with a smaller diameter is used, the eciency of the

product may be reduced and its operation may become

noisier.

Attention!

• Before proceeding with the installation, to be able to move the

hood more easily, complete the following operations:

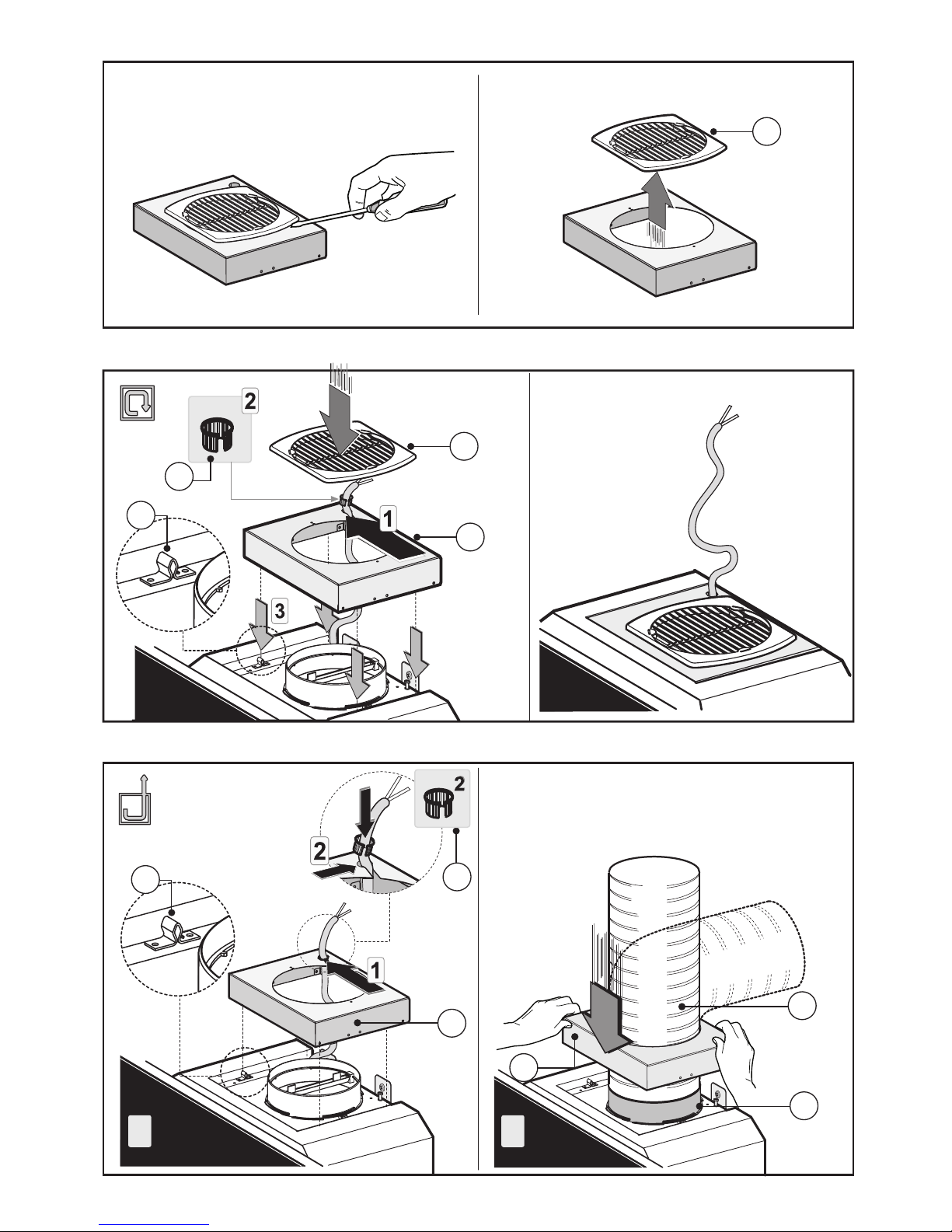

1. if the product purchased is equipped with a panel for

perimeter suction, disconnect it from the housing as shown

in gure 2 - phase 1.

2. Remove the anti-grease lterl by pulling the handle, as

shown in gure 2 - phase 2.

3. If the product is equipped with activated charcoal lters (X-

Y), remove them as shown in gure 2 - phase 3.1 or 3.2.

4. Unhook the small cupola Mas shown in gure 2 - phase 4.

Installation

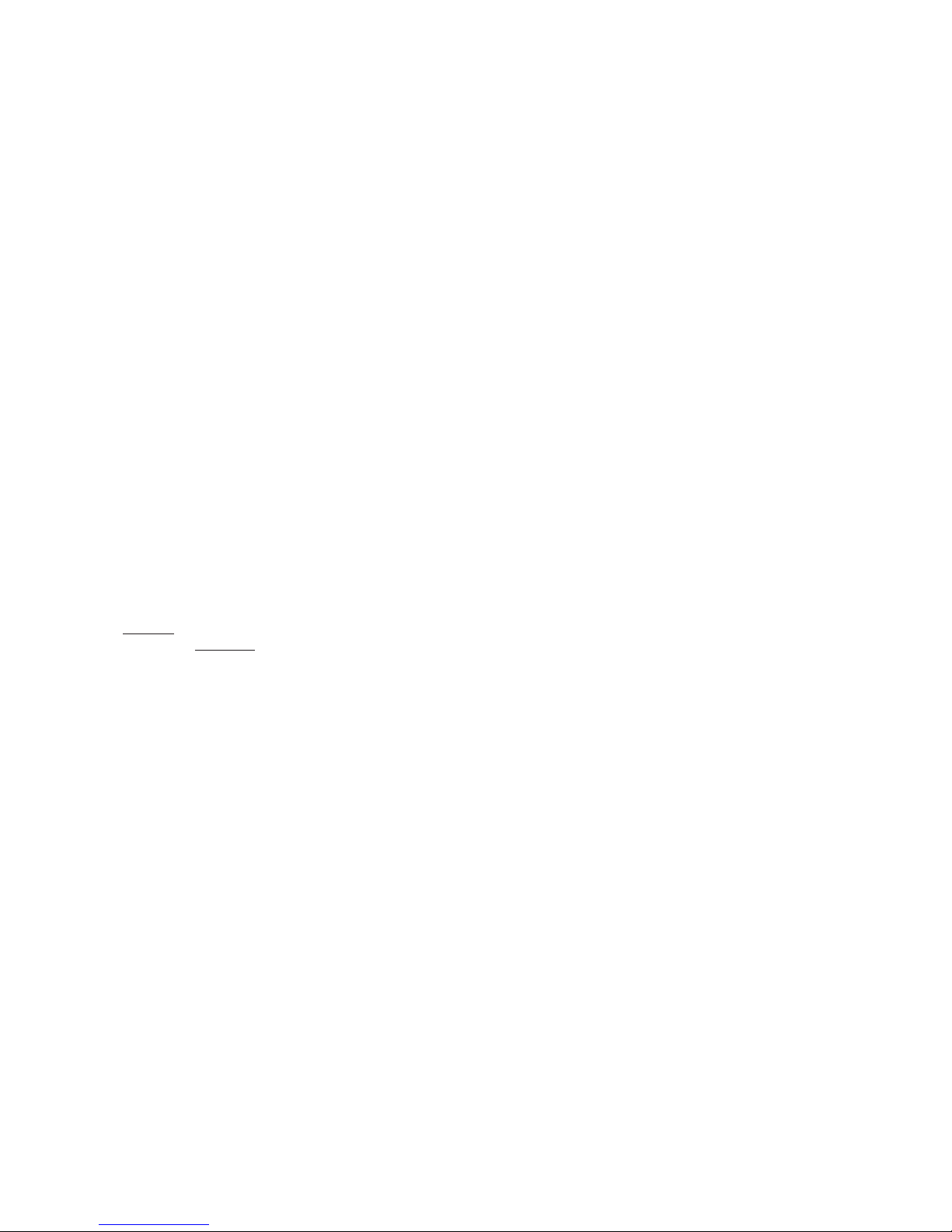

Attention! This product is supplied with the air exhaust on

the top side, however, if your needs require the use of the air

exhaust on the back side it is possible to prepare it for that

beforeinstallingthehood.To transformit,completethephases

shown in gure 8.

-Attention! It is possible to install the hood with the air

exhaust on the back side by completing the following

operations:

remove the metal sheets by striking them with a screw

driver gure 8 - phase 1-2.

Remove the screws E fastening the motor gure 8 - phase 3,

position the motor as shown in gure 8 - phase 4.

Takethe previouslyremovedscrewsEandfastenthe motor

on the back bracket as shown in gure 8 - phase 5.

Take the metal sheet F supplied with the product, and

close the air exhaust hole of the hood using the 2 screws

H gure 8 - phase 5.1

Wall mounting

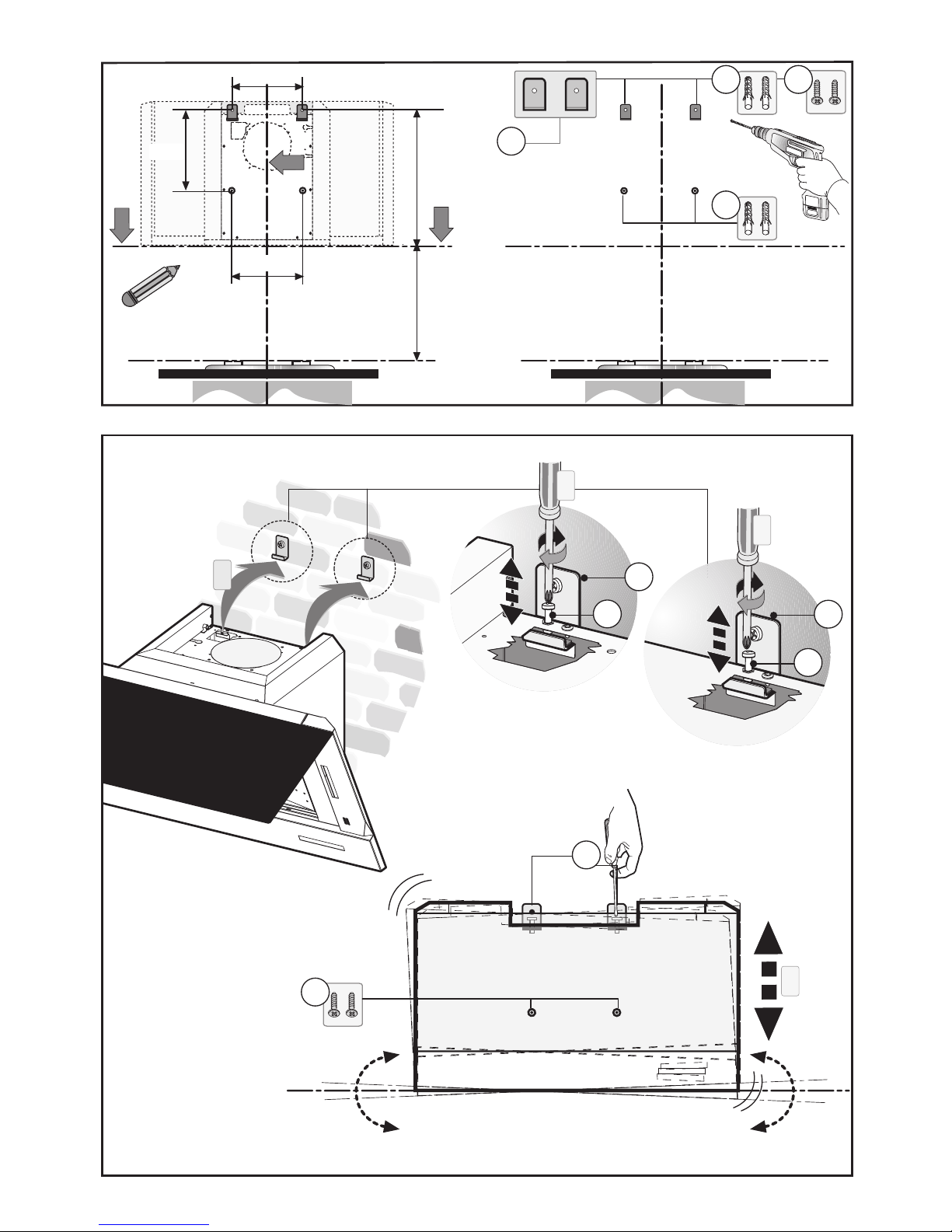

Trace the bottom side of the hood on the wall. Consider the

measurements shown in g. 3 and minimum distance from

the cooking surface.

- Mark and drill the holes, following the measurements

shown in g. 3.

- Fasten the 4 anchors Ag. 3.

- Fasten the 2 brackets Cto the wall using the 2 screws B

g. 3.

- Make sure the 2 levelling screws Dare not tight (g. 4).

- Take the appliance and hang it on the 2 brackets Cgure

4 - phase 1.

- Align the appliance horizontally using the two levelling

screws Dgure 4 - phase 2.

- Once the adjustment has been made, fasten the hood

permanently using the screws Bgure 4- phase 3.

- When carrying out the xing operations, use only screws

and screw anchors suited to the type of wall (e.g. reinforced

concrete, plasterboard etc.).

If the screws and screw anchors are supplied with the

appliance, make sure that they are suited to the type of wall

to which the hood must be xed.

• Installation of models without decorative ducts

- Extractor hood

- Unclip the canopy Mand remove the grille E(Fig. 5).

- Pass the power supply cable through the slot in the canopy

M, as indicated in Fig. 7A.

- Taking the grommet H, position it between the power cable

and the slot Fig. 7A.

- Connect the exible hose L(not supplied) to the hood, so

that it is aligned with the air exhaust outlet.

If the air exhaust is on top, use Fig. 7 as a guide; otherwise,

if it is at the rear, use Fig. 8 as a guide.

- Secure the fairing M, taking care to ensure that it is correctly

hooked on the securing pins.

- Filtering version

- Unhook the small cupola Mand remove the grille E(Fig. 5).

- Pass the power supply cable through the slots of the small

cupola Mas shown in Fig. 6.

- Take the fairlead Hand position it between the power

supply cable and the slot.

- Fasten the small cupola Mand the grille Emaking sure that

is it perfectly hooked on to the fastening pins G. (Fig. 6).

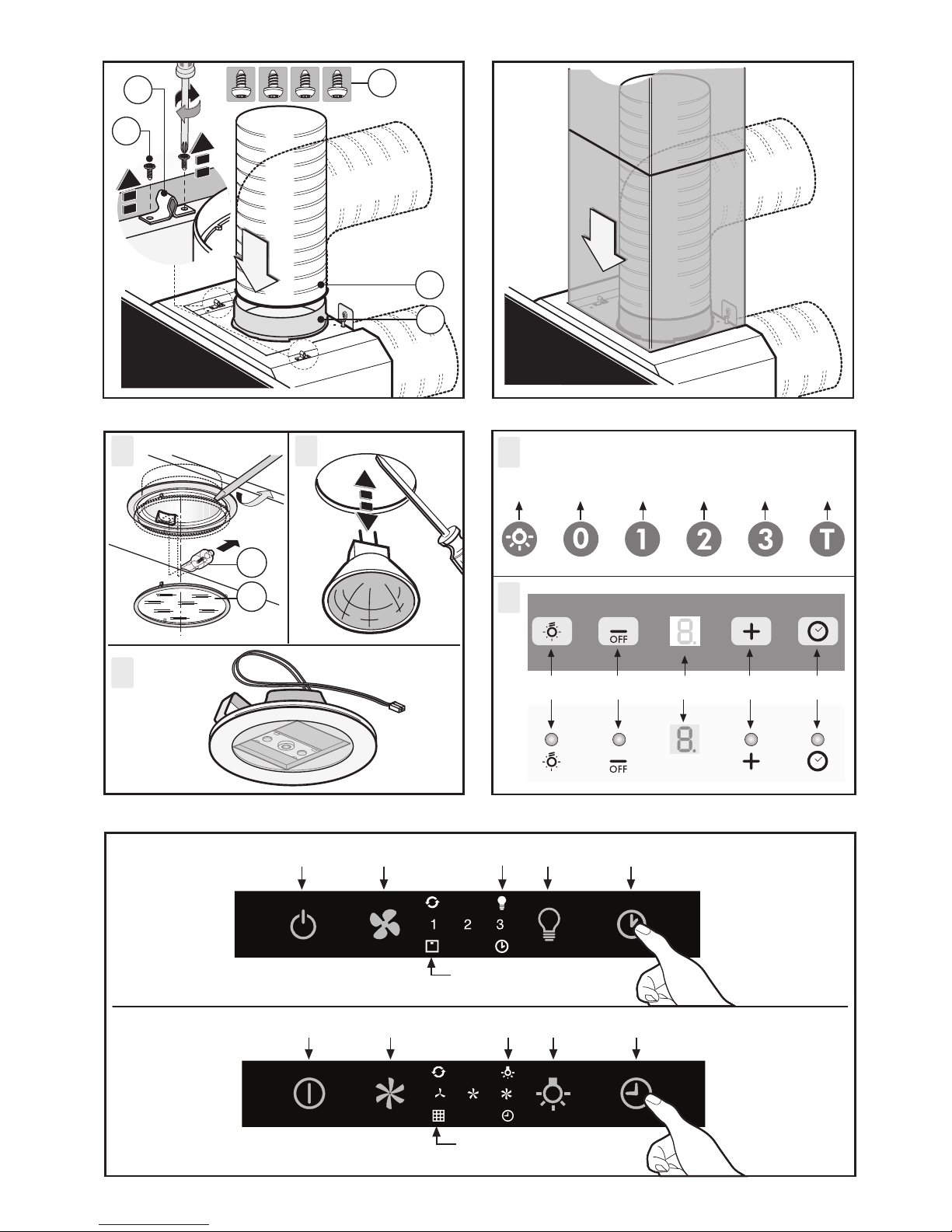

- If you find a bracket such as the one indicated in Fig.9A or

Fig.10B included in the product packaging, this should be

fixed to the hood using the supplied screws.

- Take the activated charcoal lters and position them in the

specic brackets, as shown in gure 9or 10.

• Optional accessories

This model may have decorative ducts as optional accessories

- ask your retailer for information.

Before installing decorative ues it is necessary to remove the

small cupola and loosen the 4 screws Bthat lock the fastening

pins Gas shown in Fig.12.

• Installation of models with decorative ducts - extractor

hood

Make sure the electrical power supply is within the

measurements of the decorative connector.

Adjust the width of the support bracket of the top connector

(Fig. 11).

Then x it to the ceiling so that it is on the same axis as the

hood using screws Aand observing the distance from the

ceiling shown in (Fig. 11). Connect ange Fto the air exhaust

hole using exible hose L(Fig.12).

Slide the top connector inside the lower duct and place this

on the body (Fig. 13).

Pull out the top duct as far as the bracket and secure it using

screws B(Fig. 11).

To transform the hood from a ducting version into a ltering

version, ask your dealer for the charcoal lters and follow the

installation instructions.

• Recirculation version

Please note:

In order to transform the hood from a extractor hood into

cooker hood the carbon lters must be ordered at your

retailer as accessory.

We have two different types of Kit, one with extractable

carbon filters (Fig.9) and the other one with re-usable carbon

- 10 -