7

Installing the extractor

1. Before carrying out the appliance installa-

tion, please check that all components are

not damaged, in such a case contact your

retailer and do not carry out any installation

operation.

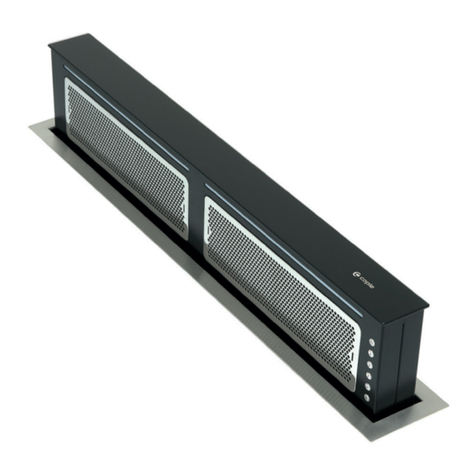

Before the installation of the Downdraft,

please remove the safety piece you can see

in the picture (Fig. 1). Furthermore, please

read carefully all of the following installation

instructions.

• Useanairexhaustingpipewhosemaxi-

mum length does not exceed 5 meters.

•Limitthenumberofelbowsinthepiping,

since each elbow reduces the air capac-

ity of 1 linear meter. (eg. if you use no. 2 x

90 ° elbows, the length of piping should

not exceed 3 meters).

• Avoidabruptdirectionchanges.,

•Use a 150 mm. constant diameter rigid

ducting pipe for the whole length.

• Use piping approved by standards in

force.

The manufacturer shall not be deemed re-

sponsible for air capacity or noise problems

caused by failure to comply with the above

instructions and no warranty on the product

shall be provided.

2. Before making the hole, check that there are

no structural or other parts inside the cabi-

net, where the appliance is to be placed,

which could hinder a proper installation.

Check that the dimensions of the Downdraft

and the ones of the cook top are compatible

with the cabinet so that the installation can

be carried out properly.

3. Make a rectangular opening, 842 x 100 mm

in size, in the back of the cook top for the

90cm model and 542 x 100 mm for the 60

cm model.

4. Put the Downdraft in the opening, inserting it

from above as shown in (Fig. 2).

5. Fix the downdraft inside the cabinet, using

the special fixing brackets supplied with the

product (Fig. 3).

Insert the brackets in the lower side of the

downdraft (Fig. 3), in such a way that there

is a 2 mm distance between the lower side

of bracket and the bottom of the cabinet

(Fig. 3).

This distance will allow the traction to be po-

sitioned downwards of the product, at the

moment of fixing, in order to have the stain-

less steel trim perfectly adhering with the

work surface. Before inserting the screws,

please make sure that the appliance is per-

fectly perpendicular with the work surface.

6. Once the installation is complete and after

connecting the appliance to the mains

power, lift up the downdraft and remove the

door block (Fig. 4); then open the door

(Fig. 5) and fit the filters in place (Fig. 6). In

the ver-sion of the Downdraft equipped with

internal motor, install the power unit

orienting the air outlet to the desired

position, either downwards or upwards

(Fig. 7). The motor can be installed either on

the front or rear side of the downdraft After

having installed the motor, connect the air

ducts.

7. For versions with an external motor, place

the external motor in a suitable area and fit

the exhaust ducting as illustrated. Then fit

the air outlet ducts between the external

motor and the downdraft. Select an air outlet

from the five possibilities (Fig. 9) and fit the

union supplied with the appliance.

8. Place the metal box with the electronic com-

ponents in an easily reachable area for even-

tual technical assistance operations. (Fig.

9), connecting the three connectors (9 pole

connector for the actuator control and the

safety control, 4 pole connector for neon

lamp turn on and push-button connector)

(Fig. 10).