3

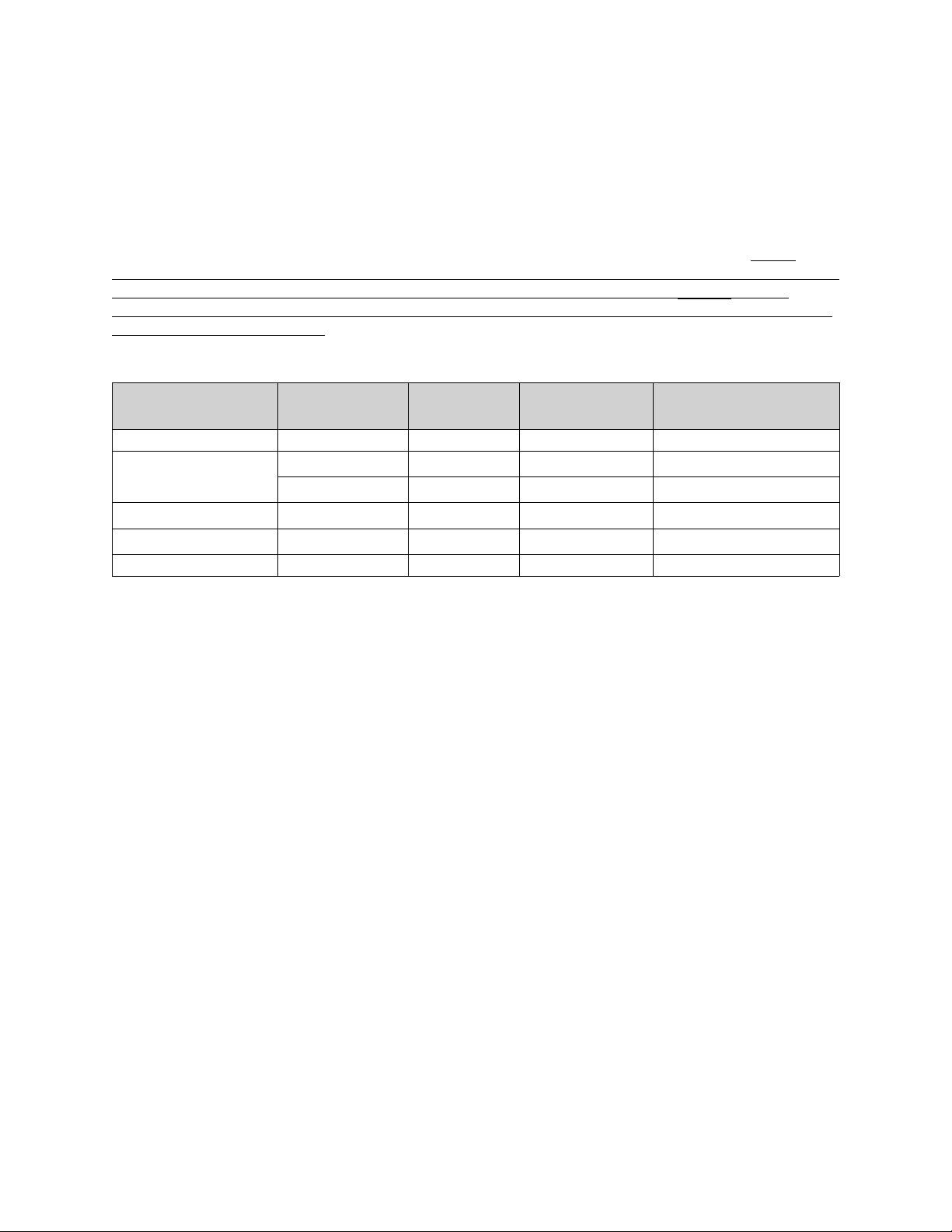

Table of Contents

WARRANTY ................................................................................................................................................4

LISTINGS ....................................................................................................................................................5

CLASSIFICATIONS .....................................................................................................................................5

APPLICATION .............................................................................................................................................6

Grease Ducts ........................................................................................................................................6

Chimneys ..............................................................................................................................................7

Clearances ............................................................................................................................................8

MECHANICAL ...........................................................................................................................................10

Joint Sealant ....................................................................................................................................... 10

Grease Duct and Chimney Joint Assembly .........................................................................................11

Double Wall Adjustable Duct, Chimney and Transition Plate .............................................................12

Double Wall Adjustable Duct, Chimney Standard Installation .............................................................14

Double Wall Offset Distance ............................................................................................................... 16

Factory and Field (Bolted and Welded) Risers ...................................................................................17

Duct Drains .........................................................................................................................................19

Manifold Tee .......................................................................................................................................19

Access Door (Tee Cap) Assembly ......................................................................................................20

Transition Plate ...................................................................................................................................21

Chimney Adapter Plate ....................................................................................................................... 22

Prevention of Grease Accumulation in Horizontal Grease Duct ......................................................... 23

Alignment & Bracing of Grease Duct ..................................................................................................23

Double Wall Horizontal Support and Support Spacing ....................................................................... 23

Vertical Support & Vertical Support Spacing .......................................................................................25

Double Wall Vertical Support (Wood, Steel, Concrete) .......................................................................29

Double Wall Vertical Ceiling Support ..................................................................................................32

Double Wall Vertical Floor Support (Wood, Concrete, Steel) .............................................................33

Vertical Support Floor and Curb ..........................................................................................................37

Through Penetration and Fire Stops ...................................................................................................38

Annular Distance – Fire Stop ..............................................................................................................39

Annular Distance – 2R Type HT Clearance ........................................................................................39

Floor and Ceiling Fire Stop Installation ...............................................................................................41

Wall Fire Stop Installation ................................................................................................................... 42

Grease Duct Assembly .......................................................................................................................43

Chimney Assembly .............................................................................................................................46

Methods Used to Test Duct After Assembly .......................................................................................49

Method 1 – Light Test per IMC 506.3.2.5 ............................................................................... 49

Method 2 – Smoke Test .........................................................................................................49

Method 3 – Pressure Testing per SMACNA’s HVAC Air Duct Leakage ................................49

GENERAL DUCT WEIGHTS .....................................................................................................................50

CLEANING & MAINTENANCE RECORD .................................................................................................52