3

TABLE OF CONTENTS

WARRANTY...............................................................................................................................................................................................4

SAFETY INFORMATION...........................................................................................................................................................................5

General..............................................................................................................................................................................................5

Installation .........................................................................................................................................................................................5

OVERVIEW................................................................................................................................................................................................6

INSTALLATION OF HARDWARE COMPONENTS ...................................................................................................................................7

RTULink ............................................................................................................................................................................................7

RTULink Control Kit Thermistors.......................................................................................................................................................7

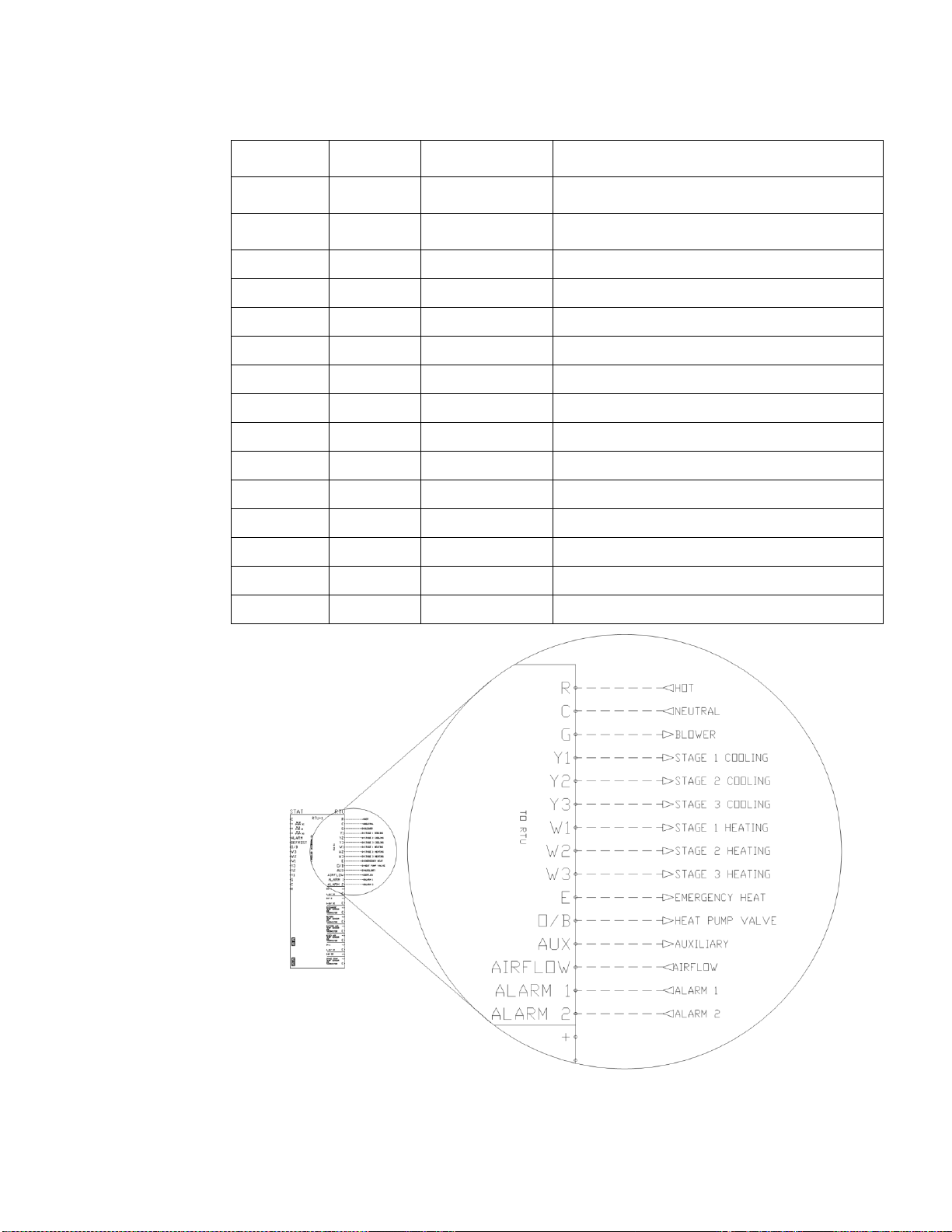

RTULink to RTU Wiring.....................................................................................................................................................................9

Thermostat (optional) ......................................................................................................................................................................10

Space Thermistor –Wall Mount (optional) ......................................................................................................................................11

Modbus Communication Wiring.......................................................................................................................................................13

Optional Sensors..................................................................................................................................................................................14

Temperature and Humidity Sensor –Wall Mount............................................................................................................................14

Relative Humidity –Duct Mount (Return or Discharge)...................................................................................................................17

Carbon Dioxide Sensor –Duct Mount .............................................................................................................................................18

Current Transducer .........................................................................................................................................................................19

Optional Outputs..................................................................................................................................................................................20

Damper/Economizer (0-10VDC)......................................................................................................................................................20

Powered Exhaust Coil Signal ON/OFF (24VAC).............................................................................................................................21

Powered Exhaust (0-10VDC) ..........................................................................................................................................................21

Occupied/Unoccupied Signal (24VAC)............................................................................................................................................22

START-UP PROCEDURE .......................................................................................................................................................................23

RTULink MODES OF OPERATION.........................................................................................................................................................24

Full Control......................................................................................................................................................................................24

Monitor Only....................................................................................................................................................................................24

External Mode .................................................................................................................................................................................24

Emergency Heat..............................................................................................................................................................................24

FUNCTIONALITY.....................................................................................................................................................................................25

Info ..................................................................................................................................................................................................25

Configuration...................................................................................................................................................................................25

Faults...............................................................................................................................................................................................29

Reboot.............................................................................................................................................................................................29

Main Board HMI Menu Tree ............................................................................................................................................................30

Space HMI and Remote Room Sensor Installation..............................................................................................................................35

Space HMI Operation...........................................................................................................................................................................36

Accessing Menu Configurations......................................................................................................................................................36

Remote (HMI) Control Panel ...........................................................................................................................................................36

Space HMI Menu Structure..................................................................................................................................................................36

Space HMI Functionality ......................................................................................................................................................................36

User Settings...................................................................................................................................................................................36

Factory Settings...............................................................................................................................................................................37

Service.................................................................................................................................................................................................40

TROUBLESHOOTING.............................................................................................................................................................................45

Faults...................................................................................................................................................................................................45

COMPONENT DESCRIPTION.................................................................................................................................................................47

Temperature Sensor –Wall Mount..................................................................................................................................................47

Current Sensor................................................................................................................................................................................47

Temperature and Humidity Sensor –Wall Mount............................................................................................................................47

Temperature and Humidity Sensor –Outdoor Mount......................................................................................................................48

Carbon Dioxide Sensor –Duct Mount .............................................................................................................................................48

APPENDIX A............................................................................................................................................................................................49

Daisy Chain Topology:.........................................................................................................................................................................49

Star Topology:......................................................................................................................................................................................49

APPENDIX B............................................................................................................................................................................................50

APPENDIX C ...........................................................................................................................................................................................52

Fixed Dry Bulb Economizer..................................................................................................................................................................52

Differential Dry Bulb Economizer .........................................................................................................................................................53

Fixed Enthalpy Economizer .................................................................................................................................................................54

Differential Enthalpy Economizer.........................................................................................................................................................55

Start-Up and Maintenance Documentation ..............................................................................................................................................56