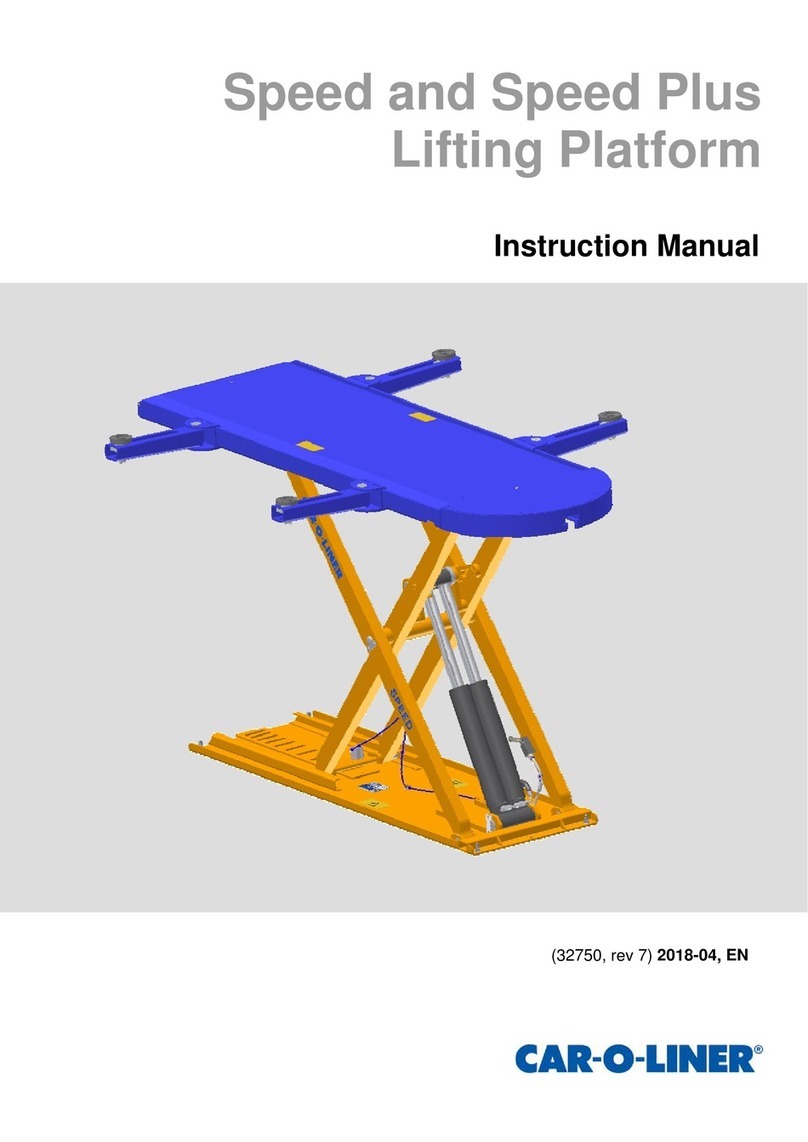

Car-O-Liner Group AB BenchRack

232163, EN- rev. 5, 2018-04

Foreword

This equipment is used to facilitate high quality re-

pairs to collision-damaged vehicles. All other use of

the equipment, or use that is contrary to the instruc-

tions in this manual, can cause personal injury and/or

equipment damage.

Car-O-Liner Group AB including any company within

the Car-O-Liner Group of companies ("Car-O-Liner")

can not be held responsible for any claims for loss or

damages as a result from incorrect use of this equip-

ment or its use in a manner not intended. Save for

product liability claims for loss or damages as a result

of personal injury or damage to property to the extent

caused by the negligence, gross negligence, breach of

contract, or other wrongdoing of Car-O-Liner (as

prescribed by the Product Liability Act (1992:18) or

similar legislation applicable on other markets), Car-

O-Liner shall in no event be liable for any loss or

damage to revenues, profits or goodwill or other spe-

cial, incidental, indirect or consequential damages of

any kind.

Warranty

Car-O-Liner offers a one-year limited guarantee from

the date of installation of the equipment at end users

premises. This guarantee covers only material defects

and assumes normal care and maintenance according

to Car-O-Liner specification.

The guarantee assumes that:

The equipment is correctly installed and inspected

in accordance with current local laws and regula-

tions.

The equipment has not been altered or rebuilt

without prior written approval from Car-O-Liner.

Genuine Car-O-Liner spare parts are used in any

repairs and conducted by Car-O-Liner certified

technician.

Operation and maintenance have been carried out

according to the instructions in this manual.

All claims on warranty shall be notified through your

authorized Car-O-Liner Distributor by use of Car-O-

Liner´s VisionWeb platform without undue delay and

shall verify that the fault has occurred within the guar-

antee period and that the unit has been used within its

operating range as stated in the specifications. All

claims shall include the product type and article number

as well as a detailed description of the problem and ac-

tions taken trying to solve it. This data is stamped on the

name plate (refer to section 1.2 "Marking" for location).

Note

This instruction manual provides advice as well as in-

structions for installation, operation, maintenance and

trouble shooting.

IMPORTANT! Read this manual carefully to become

familiar with the proper operation of the equipment.

It is recommended that you use your authorized Car-O-

Liner Distributor for maintaining, servicing and upgrading

your products. Never perform repairs, adjustments or any

other work on the products which may result in personal

injury and damage to the product.

Your Car-O-Liner Distributor employs factory trained

technicians and is focused on offering you the best overall

experience with your new Car-O-Liner product. Any revi-

sions or upgrades of the products, as required by Car-O-

Liner, shall be performed by your authorized Car-O-Liner

Distributor.

The photographs and drawings in this manual are intend-

ed only to be illustrative and do not necessarily show the

design of the equipment available on the market at any

given time. The equipment is intended for use in accord-

ance with current trade practice, applicable laws and safe-

ty regulations. The equipment illustrated in the manual

may be changed without prior notice.

The contents in this publication can be changed without

prior notice.

This publication contains information which is protected

by copyright laws. No part of this publication may be

reproduced, stored in a system for information retrieval or

be transmitted in any form, in any manner, without Car-

O-Liner’s prior written consent.

Conformity with directives and standards

The equipment is designed and manufactured by Car-O-

Liner, which is an EN-ISO 9001 and 14001 accredited

development and manufacturing organisation.

The equipment is CE-approved by Inspecta, Sweden. It is

required that only Car-O-Liner approved spare parts and

accessories are used with the equipment.

Copyright © Car-O-Liner AB, 2012