6. SAFETY NORMS

Training

•The machine must not be used by under 16’s and persons who

have not learnt the user instructions .

•The operator is responsible for third parties present in the work

area . Keep children and domestic animals at distance when the

bio-chopper is in operation .

•This machine may be used only for cutting up natural wood and

foliage . It must not be used for other purposes ( e.g. for

breaking up bottles and boxes in other materials ) .

•Work only in adequate light .

•When you start up engine check that machine is equipped with

the prescribed guards .

•Wear protective gloves and goggles while working .

Preparation / Operation

•Before beginning work check that the blades and the cutters are

perfectly fixed. If the blades show signs of damage they should

be sharpened or replaced .

•Do not use the bio-chopper when it is raining .

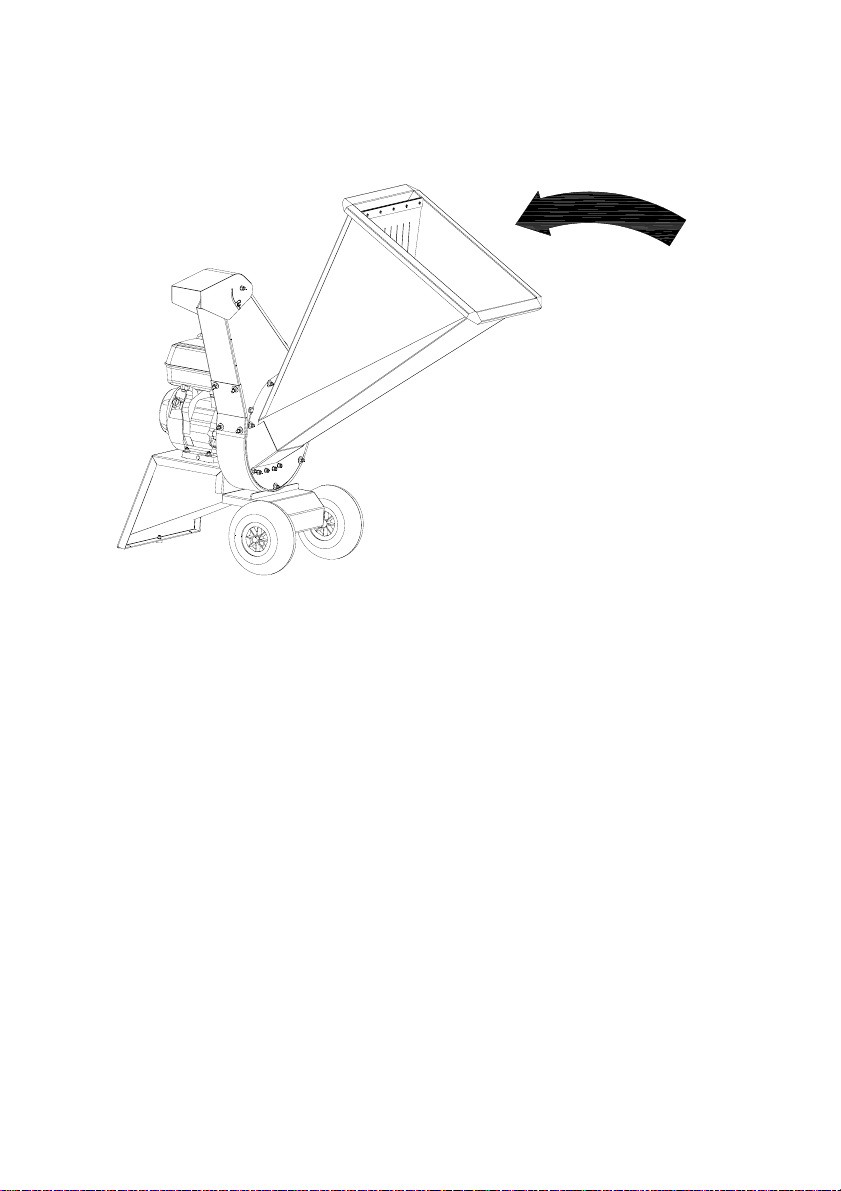

•The bio-chopper must be positioned on a flat , solid surface

where there is no danger of overturning .

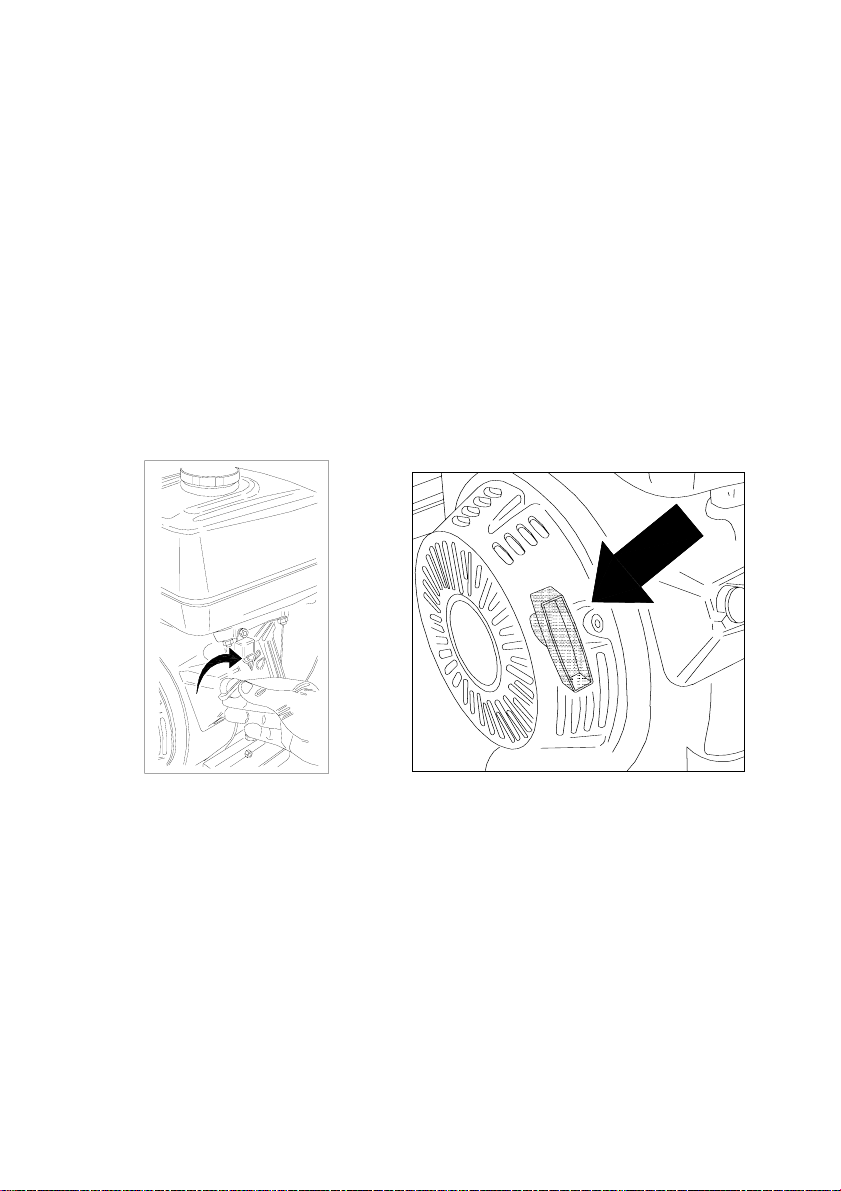

•Switch off the motor, remove the keys from the start panel and remove

the sparkplug cap ( the power supply cable for electric motor bio-

choppers , or check that the machine is disconnected from the

tractor PTO ) in order to :

-remove foreign bodies from the hoppers ;

-transport the machine or move it from the workplace ;

-carry out maintenance or cleaning ;

-leave the machine unattended .

•The blades continue to turn for a few seconds even after the

ignition has been switched off .

•Assemble the blades following the appropriate instructions and

use only original spare parts supplied by the manufacturer .

•Never use the chopper with defective guards and protection or

without the safety devices correctly fitted .

•Start up the engine with care and following the user instructions .

When the engine is functioning it is imperative to prevent anyone

from approaching the loading hopper and the discharger .