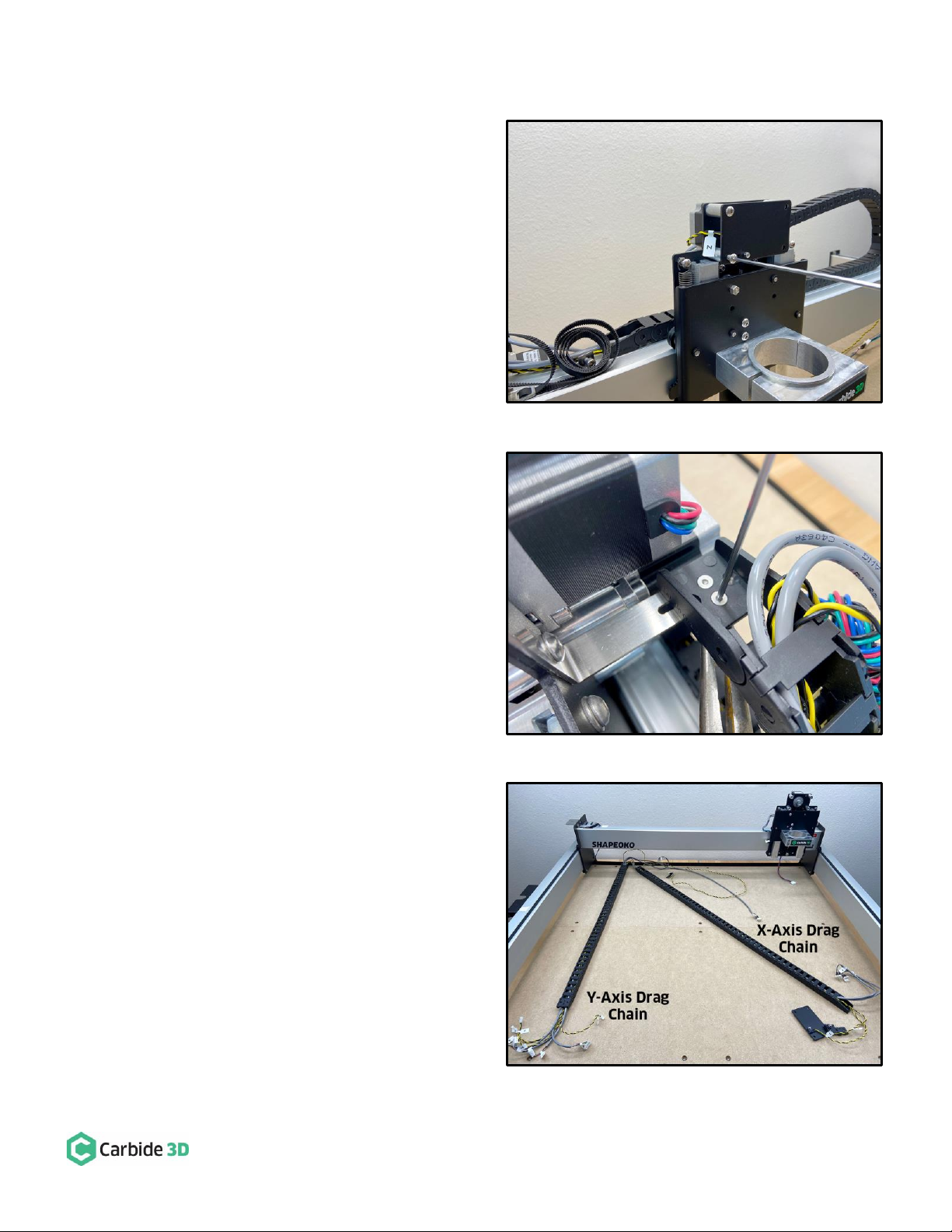

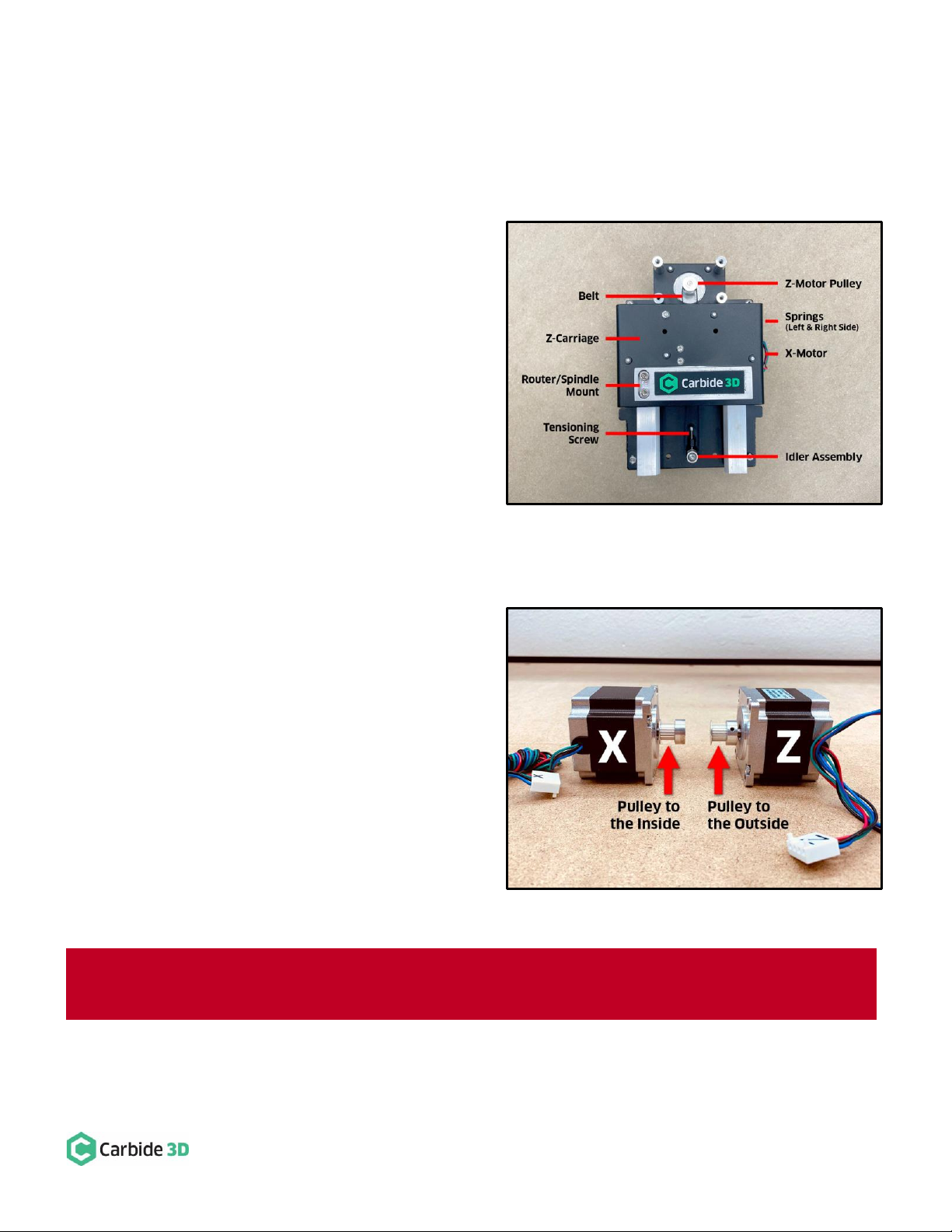

Remove the Homing Switches, Drag Chain, and X/Z-Carriage

1. Remove the Z-Axis homing switch plate from the

front of the X/Z-carriage. See Fig. 3.

a. Use a 3mm hex key to remove the four (4)

M5×10mm BHCS securing the plate. (No

need to separate any of the switches from

their mounting plates.)

2. Remove the X-Axis homing switch plate from the

rear of the X/Z-carriage.

a. Use a 4mm hex key to remove the two (2)

M5×35mm SHCS and two (2) 1-inch

spacers.

3. Remove the Y-Axis homing switch plate from the

outside of the Y2-carriage.

a. Use a 4mm hex key to remove the two (2)

M5×35mm SHCS and two (2) 1-inch

spacers.

4. Disconnect the X-Axis drag chain from the X-Axis

head bracket on the rear of the X/Z-carriage. See

Fig. 4.

a. Use a 2mm hex key and needle nose pliers

to remove the two (2) M3×8mm FHS and

two (2) nylon lock nuts securing the drag

chain to the head bracket.

5. Disconnect the Y-Axis drag chain from the Y-Axis

head bracket on the outside of the Y1-carriage.

a. Use a 2mm hex key and needle nose pliers

to remove the two (2) M3×8mm FHS and

two (2) nylon lock nuts securing the drag

chain to the head bracket.

6. Remove the drag chain from the rails and lay it on

the baseframe as shown in Fig. 5.

a. Pry the tail ends of the drag chain from

the VHB tape securing them to the rails.

b. Remove the VHB tape from the rails.

c. CARRY OVER the drag chain.

7. Remove the Y-Axis drag chain head bracket from

the outside of the Y1-carriage.