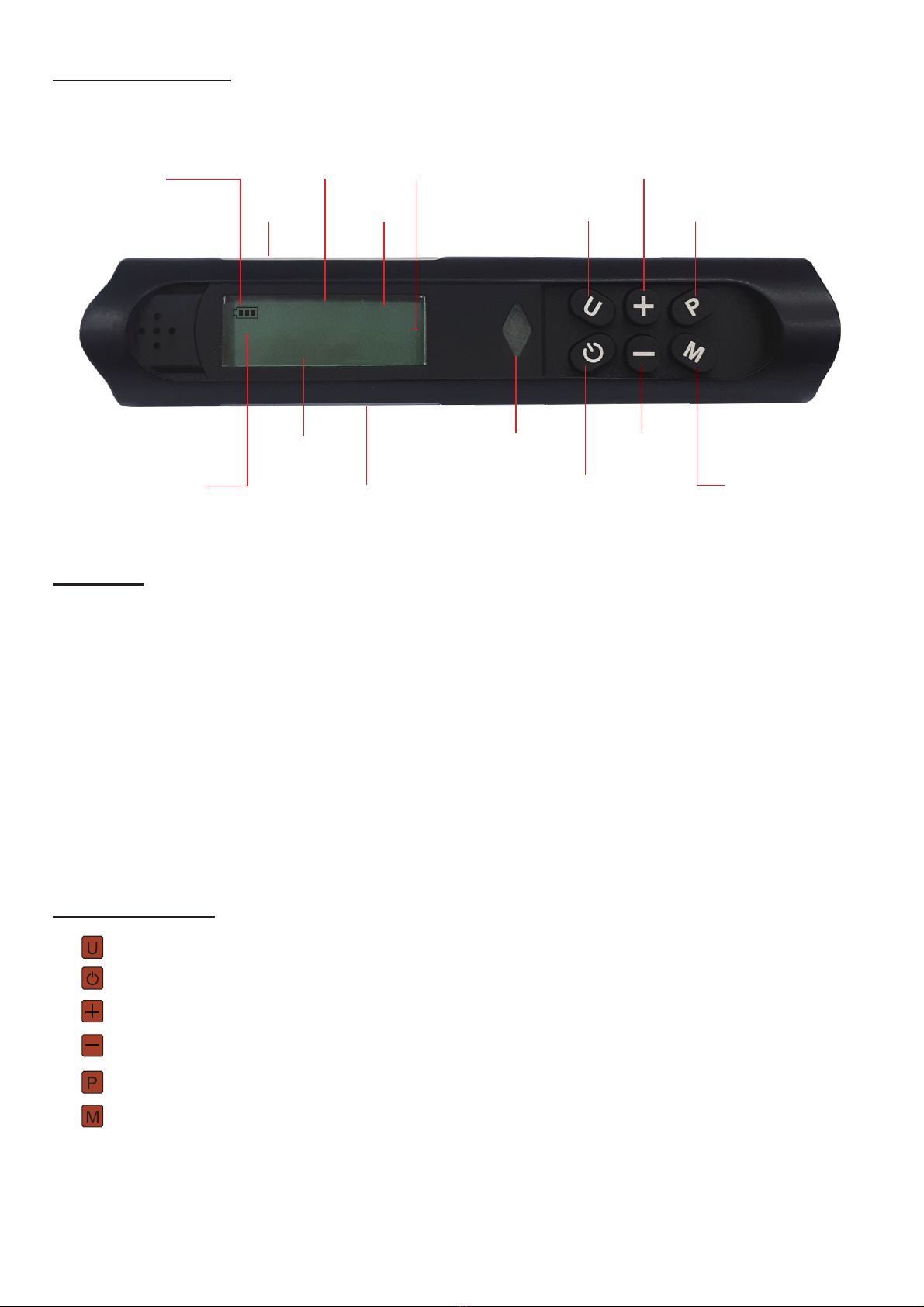

4. Preset Setting

The preset setting status will be saved in current setting. There are three set points.

Torque Value- Press UP or DOWN

value.

Unit- Press UNIT button to select torque unit or angle mode or Torque then

Angle mode.

Mode-Press MENUbutton into menu and select “MODE” to change Peak or

Track.

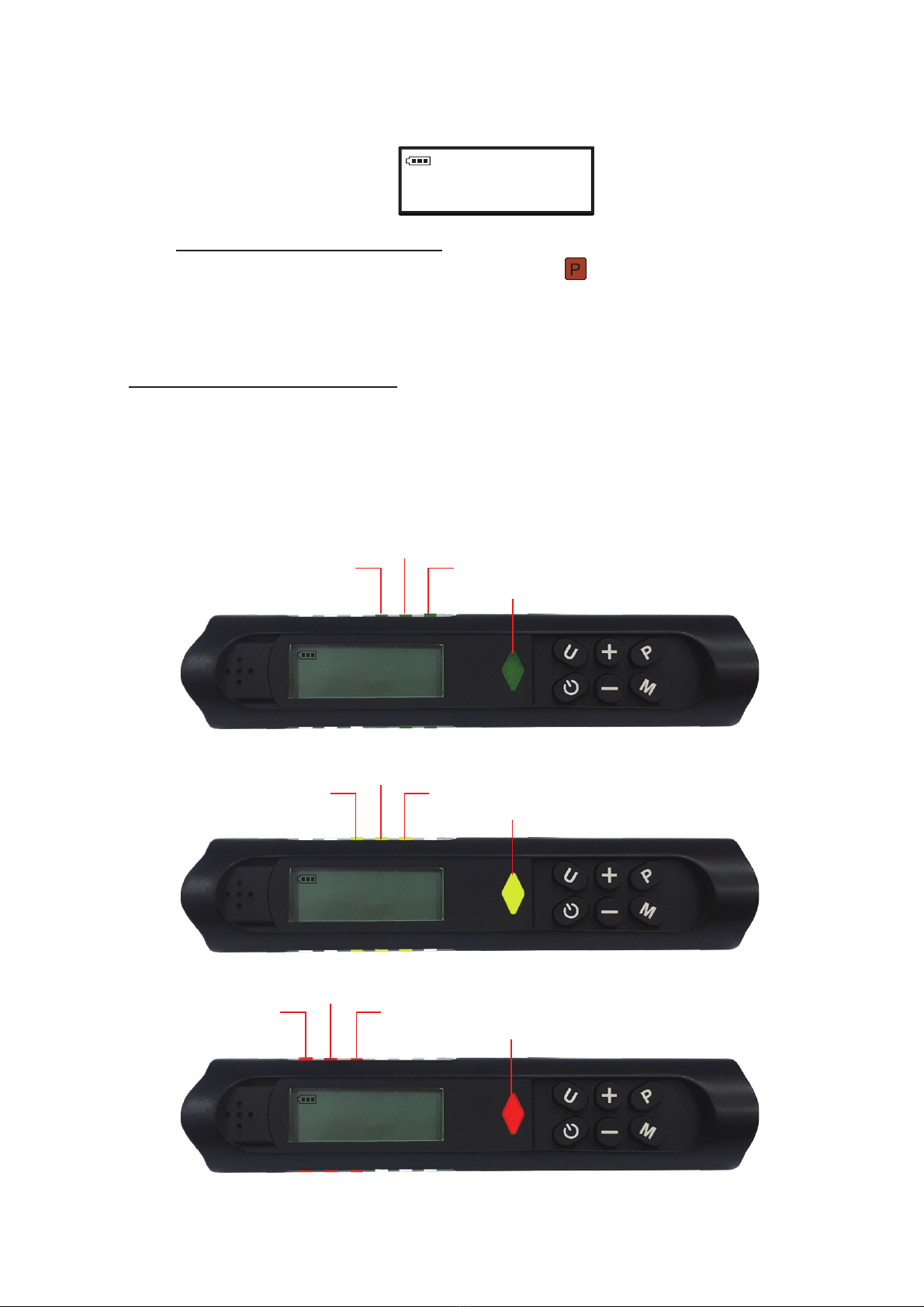

Torque Mode Measurement

Angle Mode Measurement

Torque then Angle Mode

Press "UNIT" button in Angle Mode to enter "T then A" Mode.

In this mode, you can preset

250.0 FT-LB

2015/01/01

P1 Peak

10:50

249.0 FT-LB

2015/01/01

P1 Peak

10:50

248.0 FT-LB

2015/01/01

P1 Peak

10:50

7

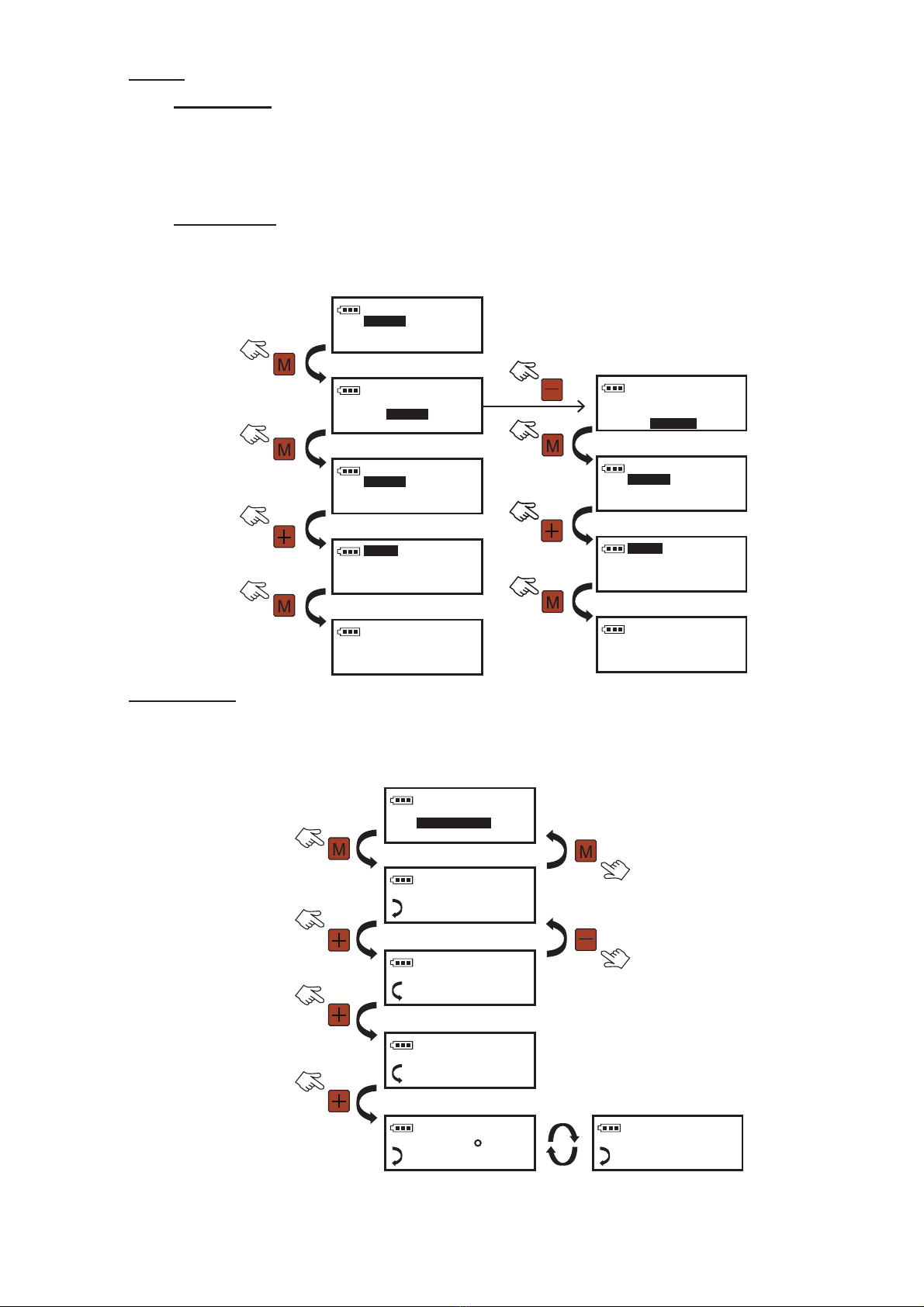

After entering Angle mode by pressing the UNIT

button and selecting your

desired units, you may start to use the angle function. When you apply the angle,

the wrench will only calculate angle degrees as the applied torque achieves 5% of

the full-scale of the torque wrench. The LCD display shows the actual applied angle

degrees. After applying angle degrees, the degree is displayed, and the display will

flash “maintain 10 seconds. The degrees can be continuously applied until reaching

the set target angle degrees. If the applied angle degrees do not reach the setting

values, the final values you apply will display the accumulated angle until clear by

pressing CLEAR or after 10 seconds to revert back to preset.

Once powered on, you may begin using the torque wrench. After force has been

applied, the LCD will display the actual torque value. Under Peak Mode, when the set

value is not reached, the LCD will display the last torque value attained. The last

reading will flash 10 seconds, but will stop flashing if additional force is applied. If the

torque value is exceeded, the peak torque will flash for 10 seconds then the LCD will

return to display the set torque value. If the torque value equals the set value, a

vibration and buzzer will automatically function.

button to increase or decrease the