10 11

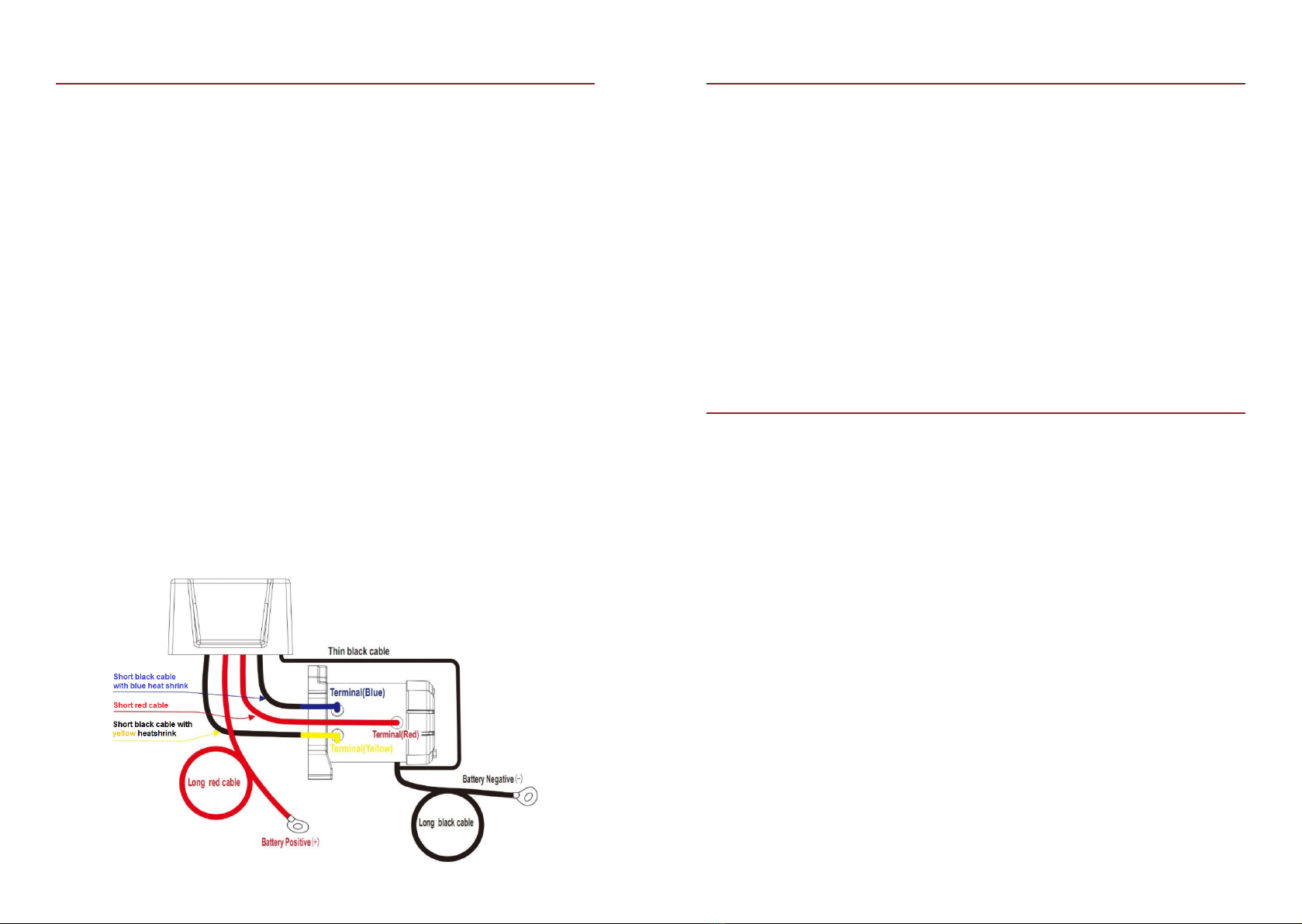

WINCH MOTOR ROTATION

In some cases you may need to rotate the winch motor for access to the motor terminals

- Stand the winch up on its gearbox side and secure

appropriately so it doesn’t fall

- Mark the location of both the bolts in relation to

the winch end plate to make it easier to realign the

motor.

- Undo both of the winch motor end bolts with a

10mm socket and remove.

- Do not remove the end cap. If you accidentally

remove the end cap make sure the seal is aligned

correctly before putting it back together.

- You may need to gently tap the main housing to

release from the drum end plate. Gently rotate the

motor body 180 degrees to the other location

- Using your alignment marks to drop the bolts back

in, you may need to slightly turn the housing back

and forth while turning the bolts with your fingers

for realignment.

- Once both bolts have dropped into their threads,

finger tighten both bolts

- Then evenly tighten to 4.5Nm torque with a 10mm

socket

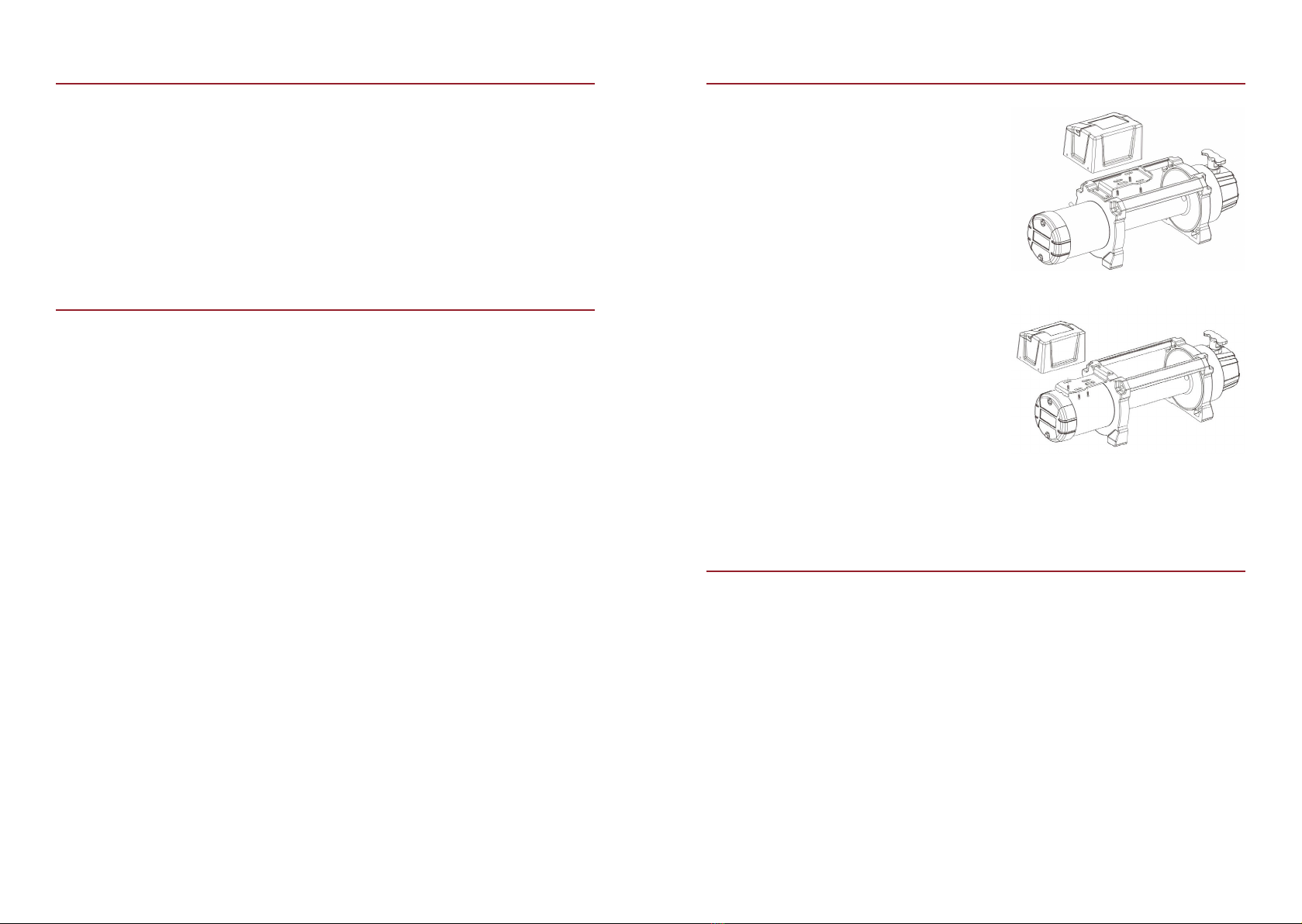

WINCH MOUNTING

Before mounting the winch ensure you have worked out the best accessible clutch handle location on the

gearbox as this is rotatable depending on bullbar/mount accessibility.

- Install mounting kit or structural support for winch

if not already fitted or included on the vehicle.

- Ensure the winch is mounted to a flat even surface

that is at least a minimum of 6.0mm thick and is

suitable for a winch mount using the supplied 4 x

square head nuts, bolts, washers and lock washers.

- These bolts must be tightened to 55 Nm of torque

and use medium grade thread locker.

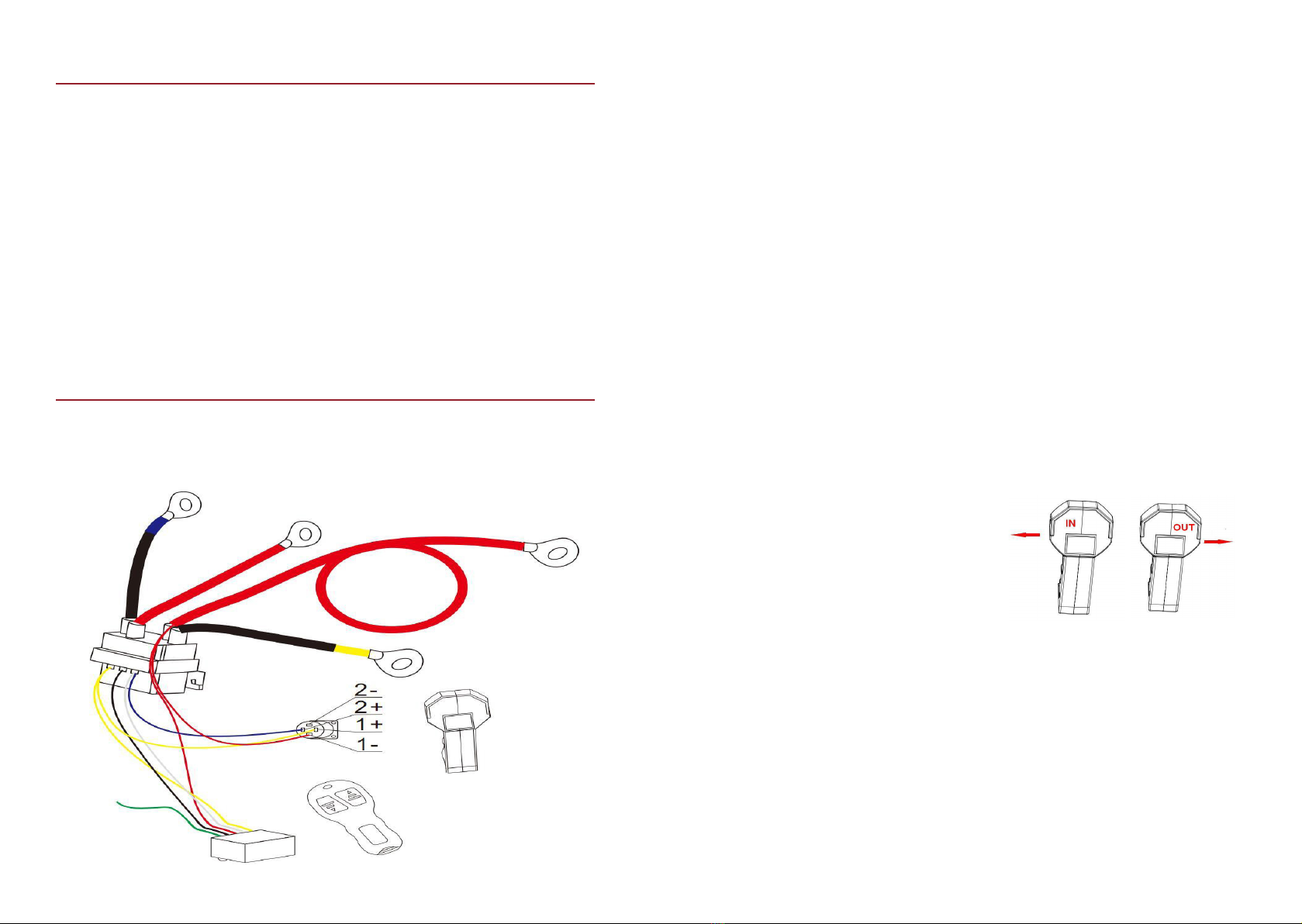

- The winch must be mounted with the arrow on the

drum end plate facing forwards and the fairlead

rope must operate from an underwound orientation.

CAUTION: In some factory bullbars from Nissan

and Toyota it is mandated due to the position of

the winch in the cradle that the rope is exited off

the top of the drum to line up with the rope outlet

on the bar. In this case the winch will need to be

fitted with the arrow pointing back towards the

engine, the rope should then be fed back around

the back of the drum and over the top to exit the

winch in this manner. You must consult the OEM

winch cradle installation manual from your vehicle

manufacturer for confirmation. WARNING: Do

not unspool the rope and wind back on the other

way, this may cause damage and failure of the

automatic brake mechanism.

- Place the square nuts inside the winch feet slots on

the winch. (Pro tip - silicone the nuts into position

to prevent them from falling out when you are

mounting a winch to the plate)

- Thread the 4 x bolts with the flat and lock washers

provided into the nuts in the winch and tighten.

- Attach the fairlead to the mounting plate using

the supplied 2 bolts, nuts, flat and lock washers

provided and use a medium lock tight. Tighten to

45 Nm of torque

- The ends of the mounting bolts must not bottom

out in the winch body and must fully engage the

threads in the nuts. If this occurs add additional

washers to the bolt to prevent bottoming out.

- WARNING: Make sure there are no sharp edges

that can contact the winch rope during operation.

You must visually inspect the rope path from the

winch drum all the way through to the outlet of

the fairlead. On some bullbar models the fairlead

mounting holes are not centrally located to the rope

outlet, and you may find that when the fairlead

is mounted the rope will be touching the inside

edge of the steel rope outlet before it feeds onto

the fairlead. It is vital to ensure that the fairlead

position is such that no other component of the

bar will touch the rope from fully wound in to fully

wound out. You will note that the angle of rope

outlet off the drum changes as it is spooled in or

out, so check both extremes for clearance. The

rope will break under load if it is subjected to any

edge or component that is not the fairlead mount.

- Ensure the mounting surface for the winch is flat

for correct winch alignment and operation

Fairlead Style Mounting - In some applications it is

easier to install the fairlead into the same mounting

holes as the bottom of the winch. Use the 2 longer

mounting bolts supplied in the bolt kit for this purpose

to run through the fairlead, mounting plate and into

the winch mounting square nut mounts. Tighten to 55

Nm of torque and fasten with thread locker.

WARNING: Do not substitute any strength grade

weaker than ISO grade 8.8 bolts and nuts