2

4068

Hydro-Pneumatic Blind Rivet Nut and StudInstallation Tool

INTRODUCTION

This brochure covers the use and maintenance of the Cardinal Components 4068 spin-pull-spin

blind rivet nut and stud installation tool. This tool is capable of placing Bollhoff Rivkle brand

blind rivet nuts in sizes from M3 metric - #6 unified, up to M12 metric – ½” unified; as well as

blind rivet nuts of other suppliers. The specific capabilities of this tool, when used with other

suppliers’ inserts, should be discussed with the Cardinal Components technical sales department.

The 4068, with a minimal amount of care, if kept clean, lubricated and operated properly for

the size inserts being installed, will provide many years of service.

The basic function of this tool can be best understood by realizing it is capable of two

separate operations – spinning and pulling.

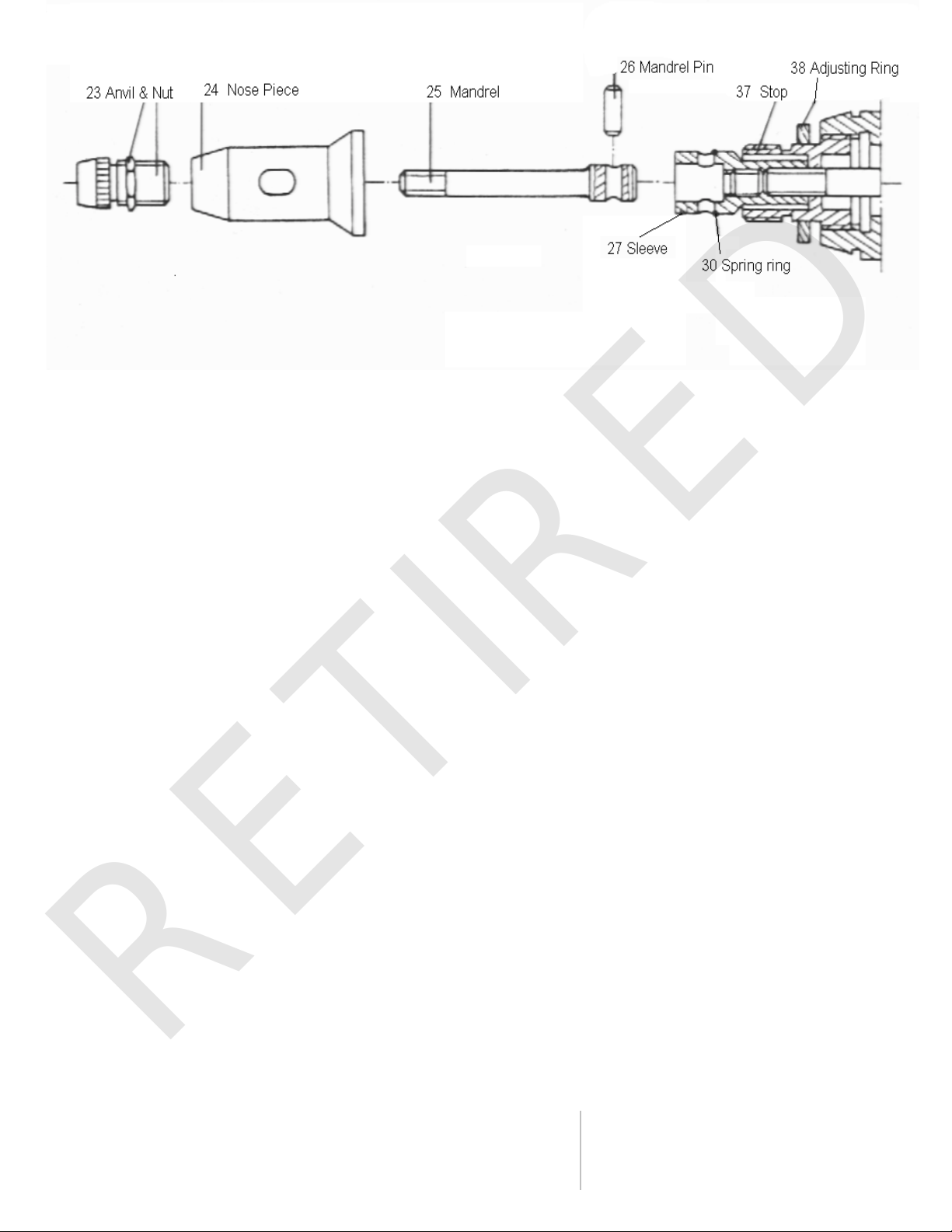

The spinningis performed bythe 4068 in both a forward motion, to mount the unplaced rivet

nut onto the threads of thedrive mandrel, and a reverse spinto disengage the drive mandrel

from the installed insert.

Once the tool has been properly set, installation of the blind rivet nut is accomplished by –

forward spin to mountthe insert onto the tool, pullbackto cause the insert to upset – reverse

spin to disengage the tool from the installed insert.

The forward spinning operation of the tool is automaticallystarted when pressure is applied to

the drive mandrel. Byholding the insert with its head toward the nosepieceor anvil of the tool

and applying pressure on the mandrel, the forward spin begins, mounting the insert on the

tool. The forward spin will stop when the insert meets the face of the nosepiece or anvil.

By pulling down on the bottom half of the “rocker” trigger, the pull stroke is performed.

By depressing the top half of the rocker trigger, the reverse spin begins to disengage the tool

from the installed insert.

The 4068 delivers a constant pulling force, or traction power, which at 85 psi. air pressure, is

5000 pounds of force. The proper installation of any size blind river nut is thereby

accomplished by a strict control of the stroke distance of the tool – the distance the tool will

pull back on the mandrel. It is extremely important that this stroke distance be properly set

duringthe initial setup of the tool priorto beginning anyinstallation of any size blind rivet nut.

The pulling force or traction power of this tool is capable of damaging the threads of the

insert, or even stripping the threads of small inserts, if not properly set.

ISO 9001 CERTIFIED

Readyto upgrade to the latest tooling?

Request your quote withRivet Nut USA (anoperating divisionofCardinalComponents, Inc.)

CardinalComponents, Inc. is your authorized preferred specialtyfastener distributor.

(800)236-3200

Sales@RivetNutUSA.com

www.RivetNutUSA.com