GENERAL

CARGO FLOOR USER MANUAL

We would like to introduce to you the right operation of our Cargo Floor system with the help of the

following data and we also want to point out to you the steps that you can take to solve malfunctions.

Please read and follow our instructions carefully so that the Cargo Floor system will give you reliable and

trouble free service for many years and health and safety is secured.

If the Cargo Floor system does not operate at all (or properly) after following the instructions, please do

not hesitate to contact your nearest agent, who will with no doubt assist you in solving the problem.

Please pay particular attention to the contents of the “Important recommendations and guidelines” on

page 2 and further!

The measurements given in this instruction start with the metric system after which between brackets [0]

the US/imperial measurement is mentioned.

TABLE OF CONTENTS

GENERAL................................................................................................................................................1

Important recommendations and guidelines.......................................................................................................... 2

Health and safety short list..................................................................................................................................... 5

Emergency stop ..................................................................................................................................................... 5

Start up check list before operation (unloading / loading)...................................................................................... 5

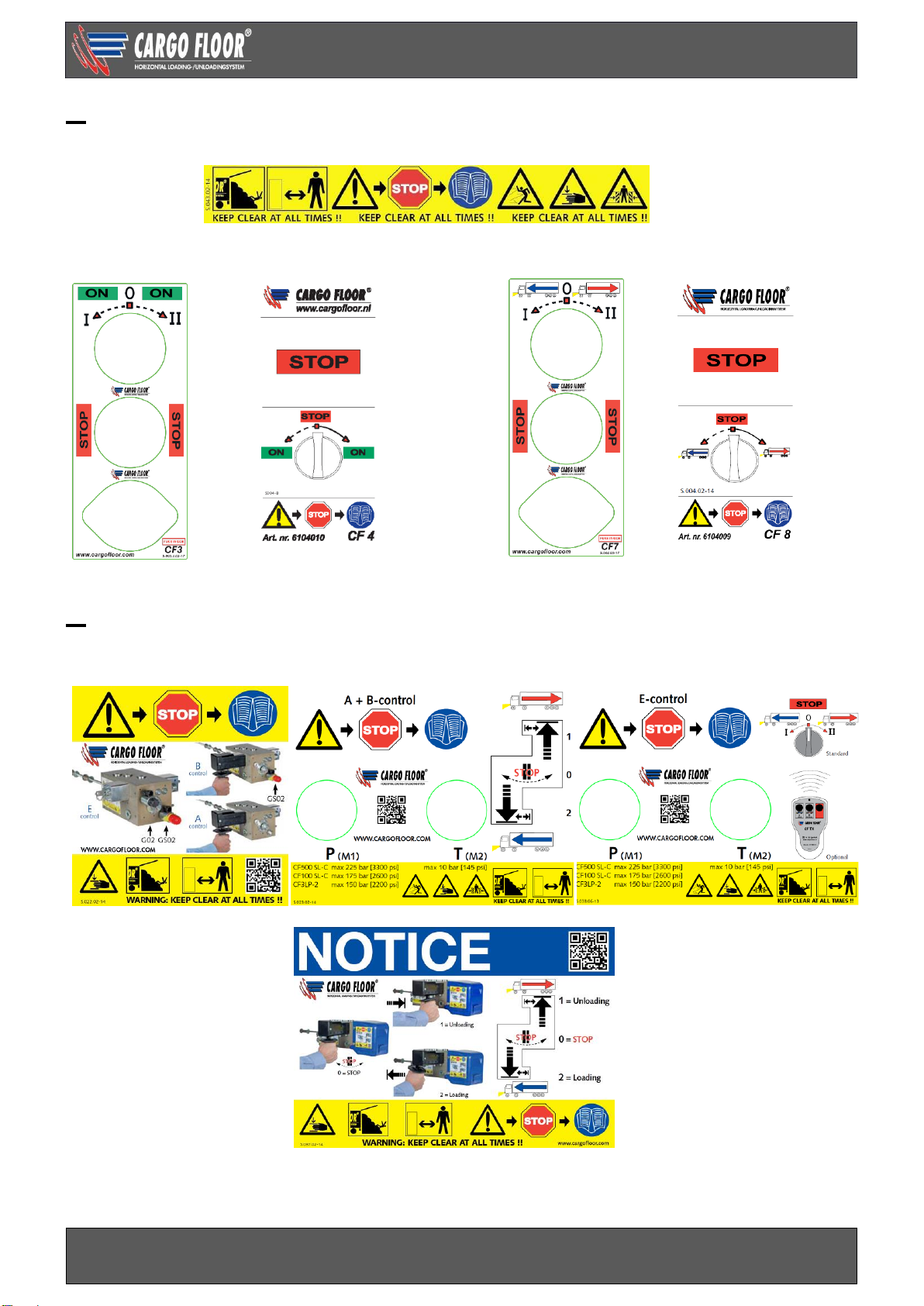

Stickers................................................................................................................................................................... 6

How to check the chosen loading/unloading function............................................................................................ 8

Modular operating possibilities............................................................................................................................... 9

Wet kit information................................................................................................................................................ 10

Hydraulic start-up check list for the Cargo Floor system ..................................................................................... 11

Identification plate ................................................................................................................................................ 12

Cargo Floor technical specifications .................................................................................................................... 13

Maintenance instructions...................................................................................................................................... 14

Adjustment of the threaded rod of the control valve ............................................................................................ 15

Warranty conditions.............................................................................................................................................. 16

A-CONTROL..........................................................................................................................................18

Control valve......................................................................................................................................................... 18

Loading –unloading function ............................................................................................................................... 18

Hydraulic circuit diagram A-control ...................................................................................................................... 19

Troubleshooting A-control valve........................................................................................................................... 20

B-CONTROL..........................................................................................................................................21

Control valve......................................................................................................................................................... 21

Loading –unloading function ............................................................................................................................... 21

Function of B-control Switches............................................................................................................................. 22

App receiver ......................................................................................................................................................... 23

Remote control (CF TX) Transmitter.................................................................................................................... 23

Manual override.................................................................................................................................................... 24

Electrical circuit diagram B-control....................................................................................................................... 25

Hydraulic circuit diagram...................................................................................................................................... 26

Troubleshooting B-control valve........................................................................................................................... 27

E-CONTROL..........................................................................................................................................28

Control valve......................................................................................................................................................... 28

Function of E-control switches ............................................................................................................................. 28

App receiver ......................................................................................................................................................... 30

Remote control (CF TX) Transmitter.................................................................................................................... 30

Manual override.................................................................................................................................................... 31

Electrical circuit diagram E-control....................................................................................................................... 32

Hydraulic circuit diagram...................................................................................................................................... 33

Choke................................................................................................................................................................... 34

Troubleshooting E-control.................................................................................................................................... 35

CONTACT DATA...................................................................................................................................36