MN90200A 090117

Model 90200A and G Microprocessor Temperature Controls — Data sheet

Electrical shock hazard: Disconnect power to appliance when wiring or servicing any electrical component.

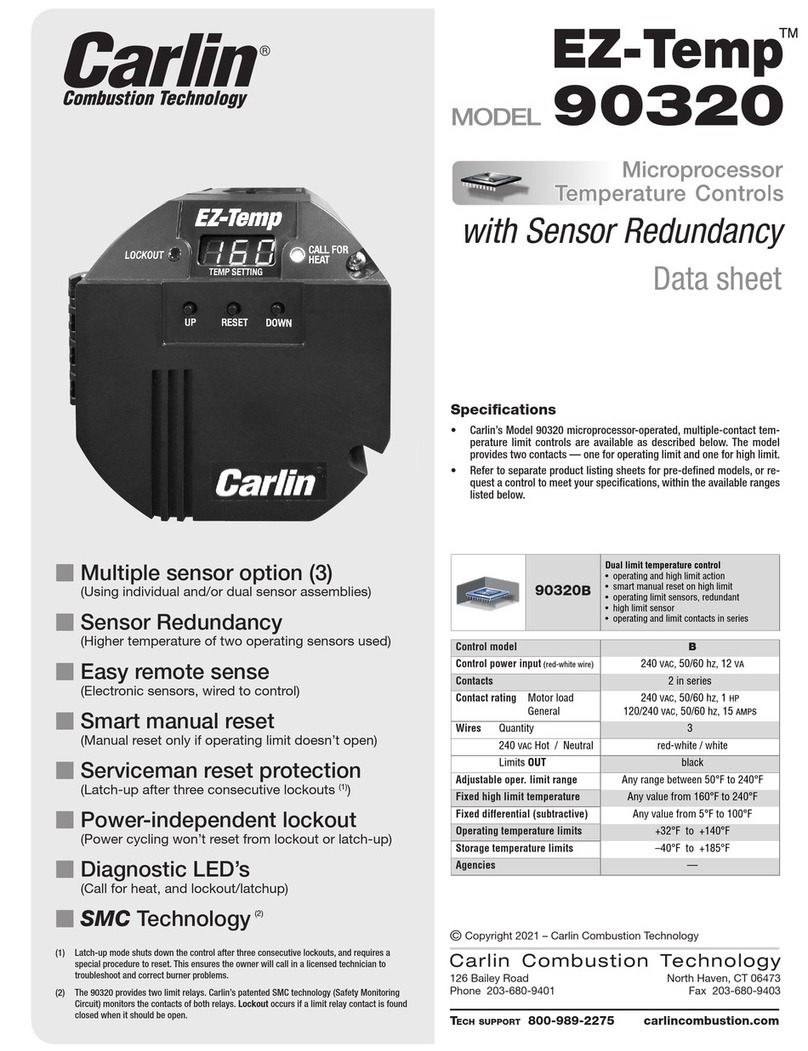

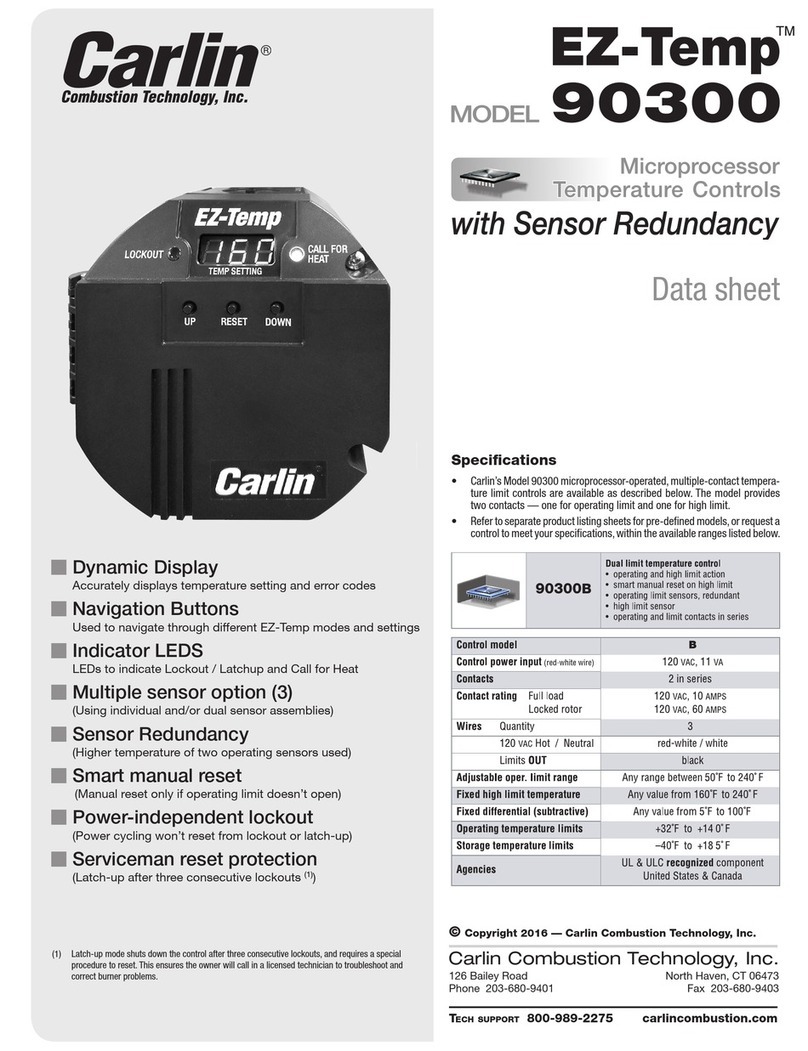

Model 90200A and G

Diagnostic LED’s

Button Press Instructions

R A

R A

125

RA

125

R A

125

RA

E0 1

RA

E0 1

RA

E0 1

Power Off

Power On

No Call for Heat

Call for Heat

Lockout

Latchup, red flashes

every 2 seconds

Primary Relay

Warning, red flashes

every 5 seconds

Quickly press the UP or DOWN button to display temperature.

Press and hold UP and DOWN buttons for 5 seconds to enter

“Set Temperature” mode.

Press the UP or DOWN button to increase or decrease the “Set

Temperature”.

Do not press any buttons for 5 seconds to exit the “Set Tem-

perature” mode and save the new temperature.

Press and holde UP and DOWN buttons during power up to

enter “Diagnostic Mode” mode.

Press the DOWN button to move to the next error recorded in

the 16 deep error log. When you see an “E – –” displayed, you

have reached the end of the log. If you press the DOWN button

again, you will cycle back to the beginning of the log.

Press and hold RESET for 3 seconds to clear all recorded logs.

Press and hold RESET for 5 seconds to exit Lockout.

Press and hold RESET for 30 seconds to exit Latchup.

Display Mode

Set Temp Mode

Diagnostic Mode

Lockout Mode

Latchup Mode

Up Reset Down

Power, Off – (How to enter = No power is applied to the red-white wire)

• All lights and screen will be off.

Power, On – (How to enter = Power applied to red-white wire)

• System will power on and enter NORMAL OPERATION MODE

Call for Heat/High Fire – When the temperature at the operating sensor is

at or below setpoint minus fixed differential, the control powers the limit

relay.

Stand By/Low Fire – When operating sensor reaches setpoint temperature

or above, temp control will turn off the relay (break-on rise contact

opens).

Normal Operation (Mode) – (How to enter = Initial starting mode)

• The EZ-Temp will display the User Set Temperature.

Display – (How to enter = Pressing UP or DOWN key in NORMAL MODE)

• In DISPLAY MODE, the EZ-Temp will display current temperature read-

ing for 5 seconds, then return to NORMAL OPERATION

Setting – (How to enter = Hold up and down buttons for 3 seconds while in

NORMAL OPERATION)

• In SETTING MODE, the user is able to adjust the operating limit (via

setting the set temperature). Once in this mode, the display will begin

flashing the current set temperature. The display will increase one

degree per UP or DOWN button push or 10 degrees per second the

button is held.

Diagnostic – (How to enter = Power up the system with the UP and DOWN

buttons depressed. Once buttons are released, the system will move

into diagnostic mode)

• DIAGNOSTIC MODE displays recorded error codes. When powered in

this mode, the display will show the newest recorded error code. As

the DOWN key is pressed, the system will display error codes from

newest to the oldest. When there are no more codes to display, the

EZ-Temp will show a “—“ to indicate end of error codes. If the user

continues to push the down button, the system will go back to the

newest error code and begin displaying the error codes again from

newest to oldest. The only way to exit this mode is to power cycle the

system. To clear error codes (while in diagnostic mode), push and hold

RESET button for 3 seconds.

High Limit Test – (How to enter = In NORMAL OPERATION, hold RESET, UP

and DOWN buttons for 3 seconds)

• During this operation, EZ-Temp will display a flashing 180 (or your

current high temp). Pressing the DOWN button adjusts the high limit

temperature The high temp will decrease one degree for each press of

the DOWN button. If the DOWN button is not pressed for a period of 10

seconds, the unit will return to normal operation. When the high limit

is reached, the unit goes into hard lockout and displays the error code.

Lockup will follow. Holding the RESET for 3 seconds clears the lockout

and returns the high limit to default (180°). If the lockout condition has

driven the unit into latchup, the RESET must be held for 30 seconds.

Soft Lockout – (How to Enter = When any temperature sensor goes out of

range or the system has detected a high temp condition and the primary

and safety relays are still operational)

• When in this state, it will display the error code but will leave the

lockout LED off. If the condition that caused the soft lockout clears, the

system will return to normal operation.

Lockout – (How to Enter = Numerous Error Codes)

• The EZ-Temp will enter this state when an unsafe condition has oc-

curred and the user must intervene and put the system in a safe state.

Lockout can be cleared by pressing the RESET button for 3 seconds.

Latchup – (How to Enter = Occurs after 3 LOCKOUTs have been detected)

• The system will enter a safe mode and will not exit the mode without

user intervention. You can exit latchup mode by depressing the RESET

button for thirty seconds. By exiting this way, the system will reset the

lockout count back to zero.

Operation Modes

LEGEND