EZ-Temp Microprocessor Temperature Control — Instruction manual

– 2 – MNEZTA 042016

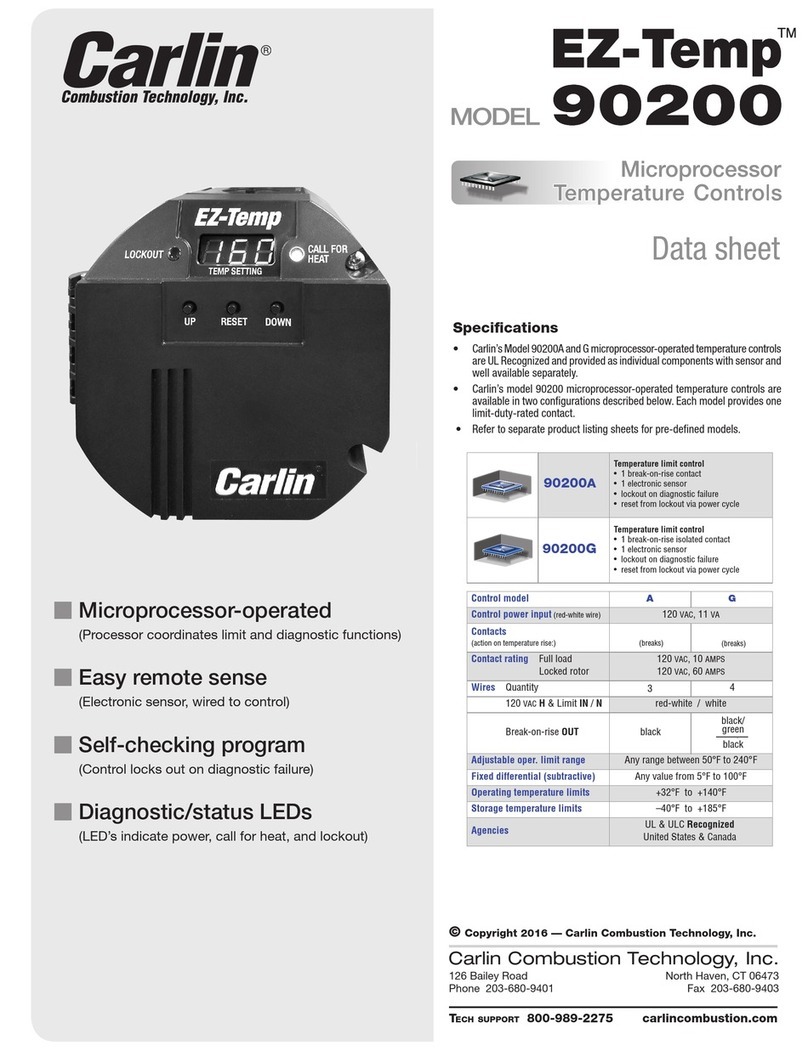

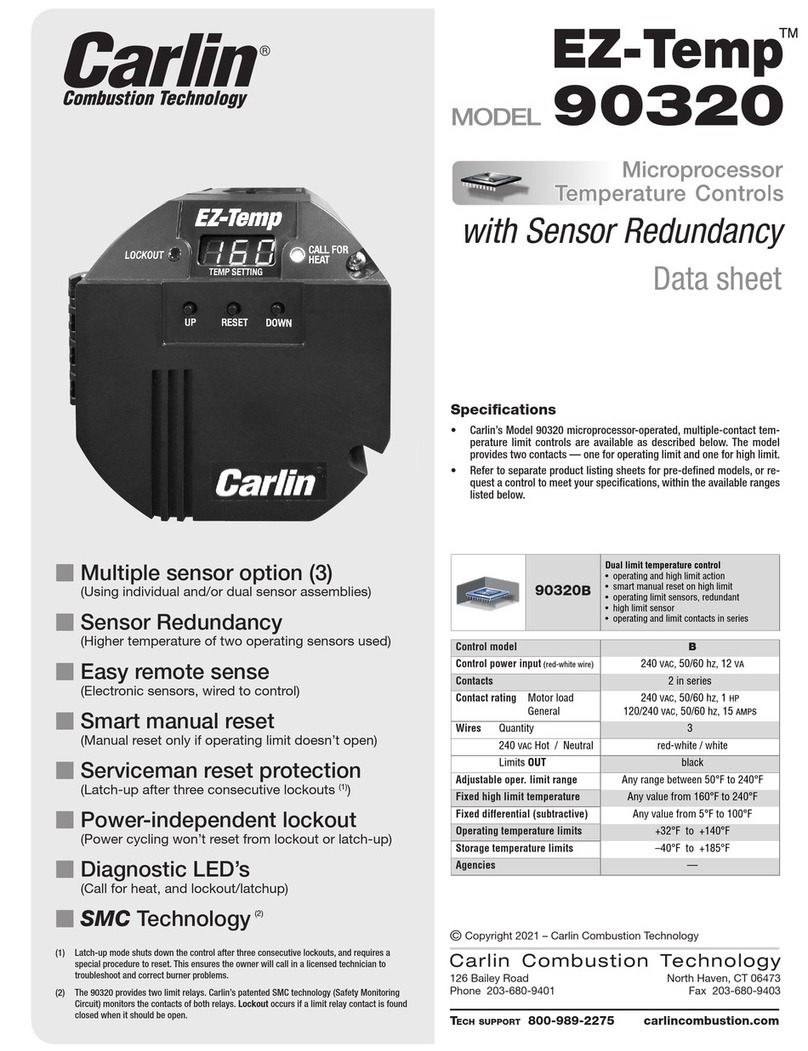

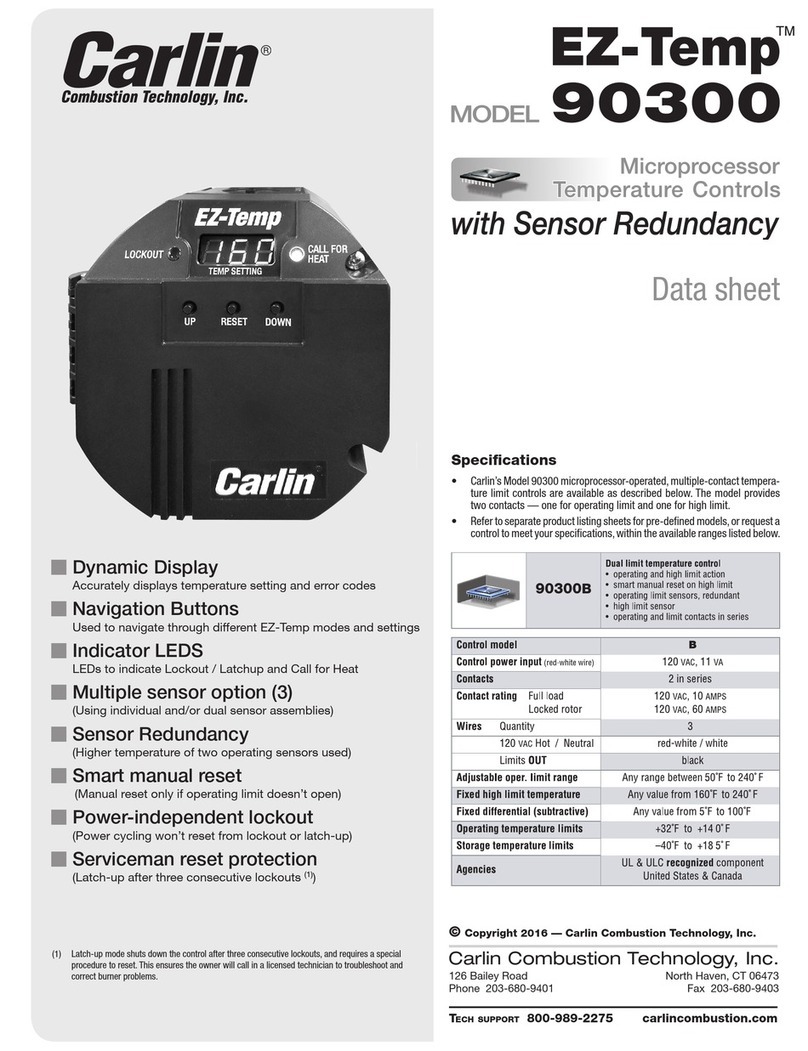

Configurations

Carlin EZ-Temp components are available in the following configurations, allowing use

with existing wells in addition to EZ-Temp wells.

Surface-mount sensors are also available.

• Control kits

Control kits include the control only.

• Well kits

Well kits include a well (item 1), rubber sensor retainer (item 3), retainer

washer (item 4), jam nut (item 5), and lock washer (item 8).

• Sensor Kits

Sensor kits include only the sensor (item 2). Sensors are available in single

and dual configurations (two sensors in the same assembly). For controls

that use multiple sensors, obtain separate sensor kits or a sensor kit with a

dual sensor.

Install sensor(s)

To install a new immersion well:

1. Turn off power to the appliance and close isolation valves.

2. Follow appliance instructions to drain the appliance so water line is below

the insertion tapping.

3. Remove existing well and sensor. Apply a small amount of pipe dope to the

new well and secure in tapping.

4. Insert EZ-Temp sensor into well and secure sensor in place as described in

the following.

5. Refill appliance with water, following appliance manual procedures.

When routing sensor wires, avoid sharp edges and use strain

relief bushings at penetrations to prevent movement or electrical

shorting of the sensor. Sensor wires are not low voltage, and must

be routed in conduit.

Configuration A: Sensor and well only

1. Insert the sensor into well (1) until the sensor (2) tip bottoms in the well

socket.

2. EZ-Temp well: Slide the rubber retainer (3) over the sensor wires until it

firmly contacts the sensor casing. Slide the retainer washer (4) and the jam

nut (5) over the wires. Thread the jam nut into the well until snug.

3. Existing well: Use the retainer spring (11) with rubber retainer (3) to seat the

sensor in the well.

Configuration B: Sensor, EZ-Temp with Carlin well

1. Insert the sensor into well (1) until the sensor (2) tip bottoms in the well

socket.

2. Slide the rubber retainer (3) over the sensor wires until it firmly contacts the

sensor casing. Slide the retainer washer (4) over the wires.

3. Slide the lock washer (8), wiring base (7), and jam nut (5) over the wires.

4. Thread the jam nut into the well and tighten to secure the wiring base and

sensor in place.

Configuration C: Sensor, EZ-Temp and non-Carlin well

1. Install well clamp assembly into wiring base.

2. Assemble wiring base to well.

3. Insert the sensor into well (9) until the sensor (2) tip bottoms in the well

socket.

4. Slide the rubber retainer (3) over the sensor wires until it is near the well (9).

5. Assemble retainer spring (11) about retainer (3) then use retainer spring/

retainer to bottom the sensor in the well. The retainer spring will lock in the

well.

Wire the control

1. Control wiring must be routed through conduit or electrical enclosures. Follow

all applicable codes and the appliance manual.

2. Insert sensor wires into the connector(s) on the face of the circuit board.

3. Follow the burner and appliance wiring diagrams to connect the control(s)

into the appliance limit circuit.

4. For specific applications, contact your Carlin supplier for further information.

Set the control

1. Follow the appliance manual to set the correct limit temperature for the

appliance. To adjust the EZ-Temp control:

Setting – (How to enter = Hold up and down buttons for 3 seconds while in

NORMAL OPERATION)

• In SETTING MODE, the user is able to adjust the operating limit (via setting the

set temperature). Once in this mode, the display will begin flashing the current

set temperature. The display will increase one degree per UP or DOWN button

push or 10 degrees per second the button is held.

2. Test the operation of the appliance and the new limit control(s) to verify

correct operation.

3. NOTE: EZ-Temp controls have a subtractive differential – control contacts

trigger when the temperature setting is reached. Contacts reset after tem-

perature drops below setpoint minus the differential amount. aCarlin well

bEZ-Temp sensor

cRubber sensor retainer

dRetainer washer

eJam nut

fSensor leads

gEZ-Temp box

hLock washer

iNon-Carlin well

jClamp Assembly

kSensor retainer spring

1

2

3

4

5

6

8

7

9

23

6

10

11

7

B

A

C

Sensor, wiring base

& Carlin well

Sensor, wiring base

& Carlin well

Sensor only

EZ-Temp well