Specifications GB

Supply Ui10 - 16.8 VDC

Ii < 50 mA

Operating temperature -20 to +40°C (-4 to +104°F)

Pressure ≤ 10 bar @ +40°C (+104°F)

Thread 3/8” PT (ISO 228/1)

Tightening torque Max. 2.2 Nm (with teflon

tape or O-ring)

Approvals II 2G Ex ib IIB T6 Gb

Ci< 1.2 µF

Li< 2.5 mH

χ

Technische Daten D

Betriebsspannung Ui10 - 16,8 VDC

Ii < 50 mA

Umgebungstemperatur, Betrieb -20 bis +40°C

Druck ≤ 10 bar @ +40°C

Gewindedichtung 3/8” PT (ISO 228/1)

Anzugsdrehmoment Max. 2,2 Nm (Mit Teflon-

Band oder O-Ring)

Zertifizierung II 2G Ex ib IIB T6 Gb

Ci< 1,2 µF

Li< 2,5 mH

εχ

Caractéristiques Techniques F

Tension nominale de

functionnement Ui10 - 16,8 VCC

Ii < 50 mA

Température en fonctionnement -20 á +40°C

Pression ≤ 10 bar @ +40°C

Filetage 3/8” PT (ISO 228/1)

Couple de Serrage Max. 2,2 Nm (avec corps

téflon ou joint torique)

Homologations II 2G Ex ib IIB T6 Gb

Ci< 1,2 µF

Li< 2,5 mH

εχ

Especificaciones E

Tensión de alimentación Ui10 - 16.8 VCC

Ii < 50 mA

Temperatura ambiente, trabajo -20 a +40°C

Presión ≤ 10 bar @ +40°C

Rosca 3/8” PT (ISO 228/1)

Par de apriete Max. 2,2 Nm (con cinta

de teflón o junta)

Homologaciones II 2G Ex ib IIB T6 Gb

Ci< 1,2 µF

Li< 2,5 mH

εχ

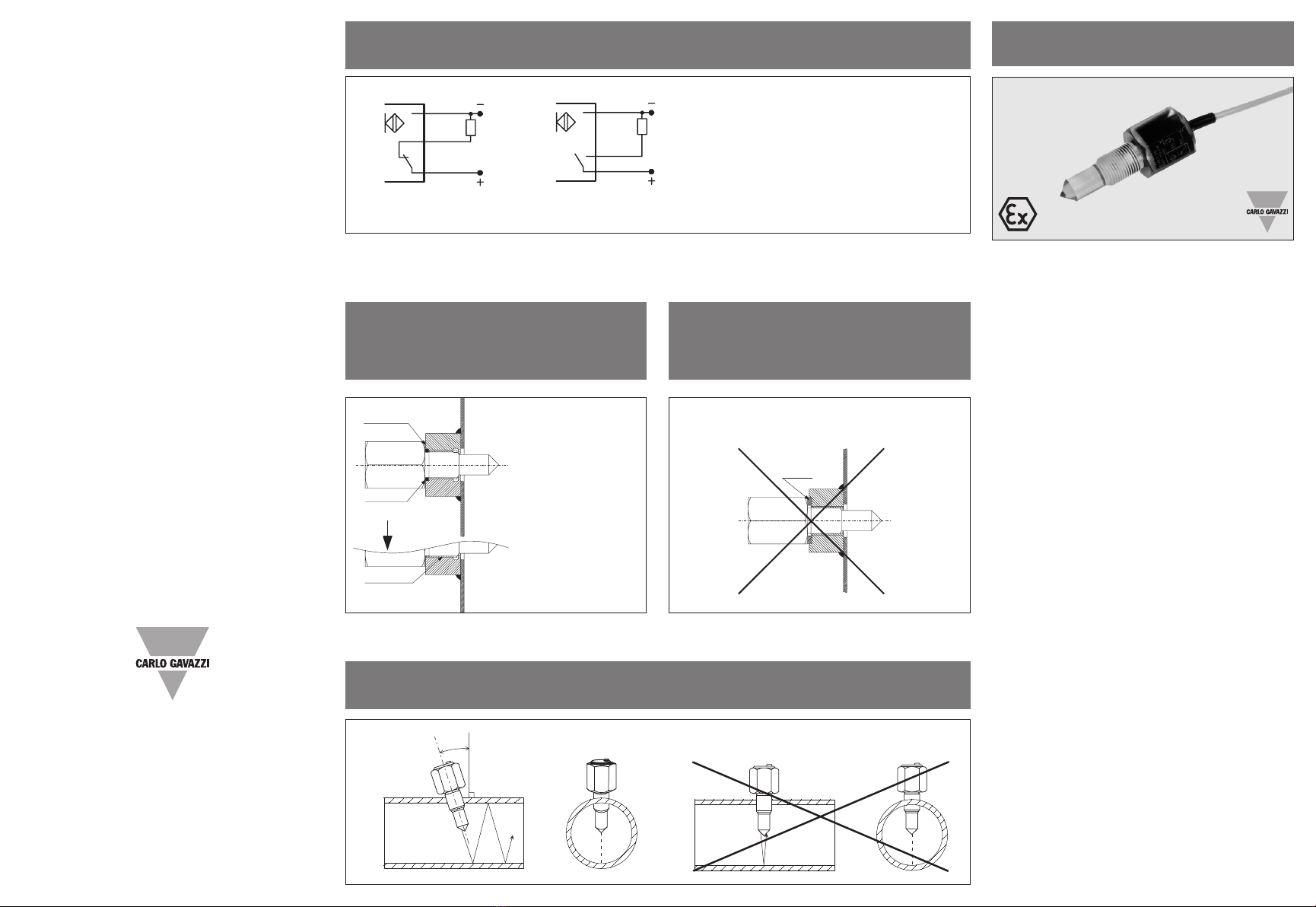

Safety notes:

- The apparatus must be operated according to the appropriate

data in the data sheet and in this instruction manual. Incorpo-

rated special conditions for safe use must be followed accord-

ing to the belonging ATEX certificate.

- For safe use in any hazardous area, the sensor must be con-

nected through a zener-barrier, fulfilling the specified Ex data of

the apparatus.

- Ex data and the ambient temperature specified on the ATEX

certificate must be respected to remain the intrinsic safety of

the apparatus. However, the construction, encapsulation and

the limited power, ensures continued safety, even at incorrect

connection (i.e. incorrect wiring, reversed polarity).

Sicherheitshinweise:

- Das Gerät darf nur gemäß den entsprechenden Angaben im

Datenblatt und in dieser Bedienungsanleitung betrieben wer-

den. Die angegebenen Sonderbedingungen für sicheren Betrieb

entsprechend der zugehörigen ATEX-Zulassung sind unbedingt

einzuhalten.

- Zur sicheren Verwendung in explosionsgefährdeten Bereichen

muss der Sensor über eine Zenerbarriere angeschlossen wer-

den, die den angegebenen Ex-Daten des Geräts entspricht.

- Die in der ATEX-Zulassung angegebenen Ex-Daten sowie die

angegebene Umgebungstemperatur müssen eingehalten wer-

den, um die Eigensicherheit des Geräts zu gewährleisten. Durch

den Aufbau, die Kapselung und die beschränkte Leistung ist je-

doch auch bei fehlerhaftem Anschluss (d. h. falsche Verkabelung

oder umgekehrte Polarität) dauerhafte Sicherheit gewährleistet.

Notes de sécurité

- L’exploitation de l’appareil doit être conforme aux données

adéquates de la fiche technique et du présent manuel. Les ins-

tructions particulières figurant dans ce manuel concernent la

sécurité d’exploitation de l’appareil et doivent être scrupuleu-

sement respectées selon le certificat ATEX qui l’accompagne.

- Pour une utilisation sécuritaire dans toute zone dangereuse,

connecter impérativement le capteur via une barrière Zener en

conformité totale avec les données spécifiques Ex de l’appareil.

- Respecter impérativement les données Ex et de température

ambiante figurant sur le certificat ATEX afin de maintenir la

sécurité intrinsèque de l’appareil. Cependant, la construction,

l’encapsulation et la limitation de puissance sont la garantie

d’une sécurité continue même en cas de connexion impropre,

de câblage incorrect ou d’inversion de polarité.

Avisos de seguridad:

- El equipo debe manejarse de conformidad con los datos co-

rrespondientes indicados en la hoja de datos y en este manual

de instrucciones. Es necesario respetar las condiciones espe-

ciales para el uso seguro incorporadas, de conformidad con el

certificado ATEX correspondiente.

- Para el uso seguro en áreas peligrosas, el sensor debe estar

conectado a una barrera zener conforme a los datos Ex espe-

cificados del equipo.

- Deben respetarse los datos Ex y la temperatura ambiente

especificada en el certificado ATEX con el fin de preservar la

seguridad intrínseca del equipo. Sin embargo, la construcción,

el encapsulado y la potencia limitada garantizan una seguridad

constante incluso con una conexión incorrecta (cableado inco-

rrecto o polaridad inversa).

Caratteristiche Tecniche I

Alimentazione Ui10 - 16.8 VCC

Ii < 50 mA

Temperatura di funzionamento -20 ÷ +40°C

Pressione ≤ 10 bar @ +40°C

Filettatura 3/8” PT (ISO 228/1)

Coppia di serraggio Max. 2,2 Nm (con nastro

in teflon o O-ring)

Approvazioni II 2G Ex ib IIB T6 Gb

Ci< 1,2 µF

Li< 2,5 mH

χ

Note di sicurezza:

-Questo apparecchio deve essere azionato secondo i dati cor-

rispondenti riportati nella scheda dati del presente manuale di

istruzioni. Le condizioni speciali incorporate per l’uso in sicu-

rezza devono essere osservate secondo il certificato ATEX di

appartenenza.

-Per l’uso in sicurezza in qualsiasi zona pericolosa, il sensore

deve essere collegato tramite una barriera Zener, che soddisfi i

dati specifici Ex dell’apparecchio.

-I dati Ex e la temperatura ambiente specificati sul certificato

ATEX devono essere rispettati per mantenere la sicurezza in-

trinseca dell’apparecchio. Tuttavia, la costruzione, l’incapsula-

mento e la limitata potenza, garantiscono la sicurezza costante,

anche con un collegamento errato (cioè cablaggio non corretto,

polarità invertita).

Specifikationer DK

Nom. spændingsområde Ui10 - 16,8 VDC

Ii < 50 mA

Omgivelsestemperatur, drift -20 til +40°C

Tryk ≤ 10 bar @ +40°C

Udvendigt gevind 3/8” PT (ISO 228/1)

Bespændingsmoment Max. 2,2 Nm (med teflon

tape eller O-ring)

Godkendelser II 2G Ex ib IIB T6 Gb

Ci< 1,2 µF

Li< 2,5 mH

χ

Sikkerhedsanvisninger:

- Enheden skal betjenes i henhold til de relevante data i sikker-

hedsdatabladet og i denne instruktionsbog. De angivne særlige

betingelser for sikker drift skal følges i henhold til medfølgende

ATEX-certifikat.

- For sikker drift i farlige områder, skal føleren være tilsluttet en

zenerbarriere der opfylder de angivne Ex-data for enheden.

- De Ex-data og den omgivende temperatur der er angivet i

ATEX-certifikatet skal overholdes for at opretholde enhedens

egensikkerhed. Konstruktion, indkapsling og den begrænsede

effekt er dog en garanti for fortsat sikkerhed, selv ved forkert

tilslutning (dvs. forkert kabling eller omvendt polaritet).

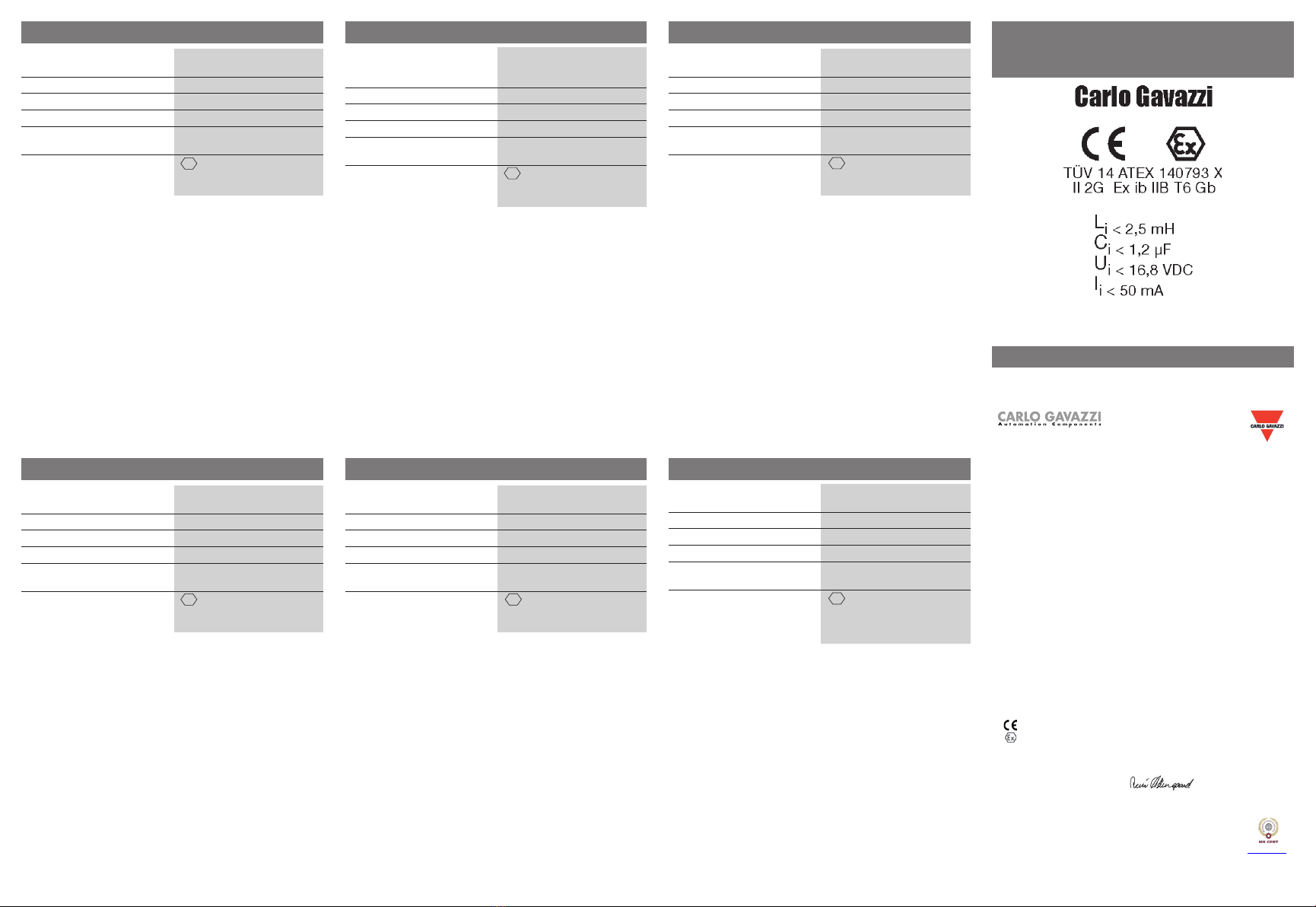

ATEX marking

ATEX Kennzeichnung / Marquage ATEX / Marca ATEX /

Approvazioni ATEX / ATEX mærkning

This Manufacturer’s Declaration of Conformity is only valid under the condition that:

- the above-mentioned products are protected against accidental touch and are installed as prescribed in the installation documentation.

- we are correctly informed about RoHS compliance of all components and raw material by the relevantsuppliers.

Technical file made up at Carlo Gavazzi Industri A/S, Over Hadstenvej 40, DK-8370 Hadsten, Denmark

Manufacturer’s point of contact: UAB Carlo Gavazzi Industri Kaunas, Raudondvario PI.101 Kaunas, LT-47184 Lithuania

ISO 9001 / ISO 14001

Issue No.: 20220222

EU Declaration of Conformity

We manufacturer

CARLO GAVAZZI INDUSTRI A/S,

Over Hadstenvej 40, DK-8370 Hadsten, Denmark. Tel. +45 89606100

declare that the product(s)

is(are) in conformity with the applicable essential requirements of the following Directives:

Low Voltage Directive 2014/35/EU

EN 60947-5-2: 2007 + A1: 2012

Low-voltage switchgear and controlgear. Part 5-2: Control circuit devices and switching

elements - Proximity switches

EMC Directive 2014/30/EU

EN 60947-5-2: 2007 + A1: 2012

Low-voltage switchgear and controlgear. Part 5-2: Control circuit devices and switching

elements - Proximity switches

ATEX Directive 2014/34/EU

Explosive atmospheres. Part 0: Equipment –General requirements

Explosive atmospheres. Part 11: Equipment protection by intrinsic safety “i”

RoHS Directive 2011/65/EU & Delegated Directive (EU) 2015/863

Technical documentation for the assessment of electrical and electronic products with respect

to the restriction of hazardous substances

_____________________________________________________________________________________________

CE marking: design and manufacturing follow the provisions of the European Directives above mentioned

ATEX marking: certificate no. TÜV 14 ATEX 140793X, NB0044 TÜV Nord

Manufacturer

Hadsten, February 22nd, 2022

René Østergaard

(R&D Manager)

EU Declaration of Conformity

2804