Introduction

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . 3

How Compound Cooling Works . . . . . . . . . . . . . . . 3

Obsolete Compressors . . . . . . . . . . . . . . . . . . . . . 3

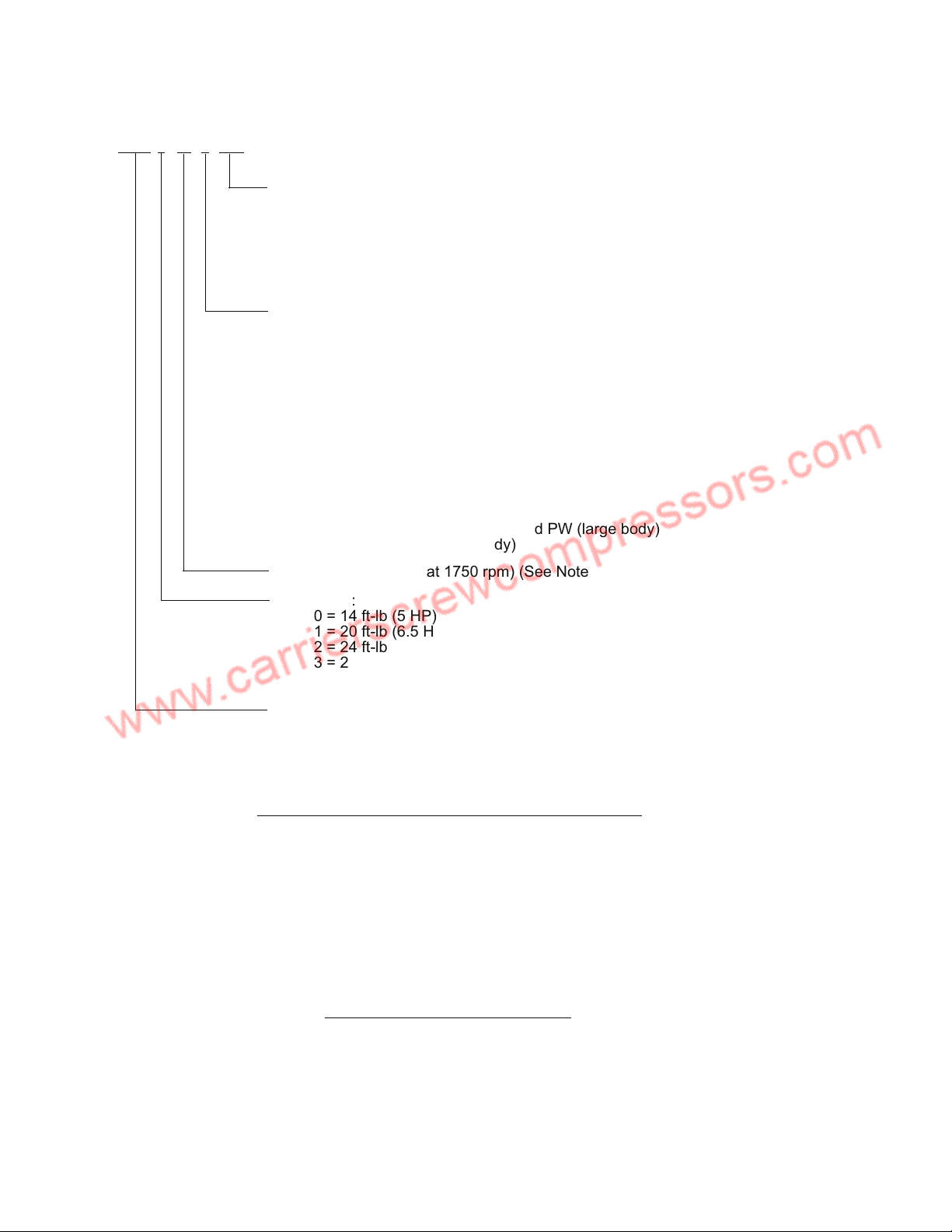

06CC Model Number Significance . . . . . . . . . . . . . 5

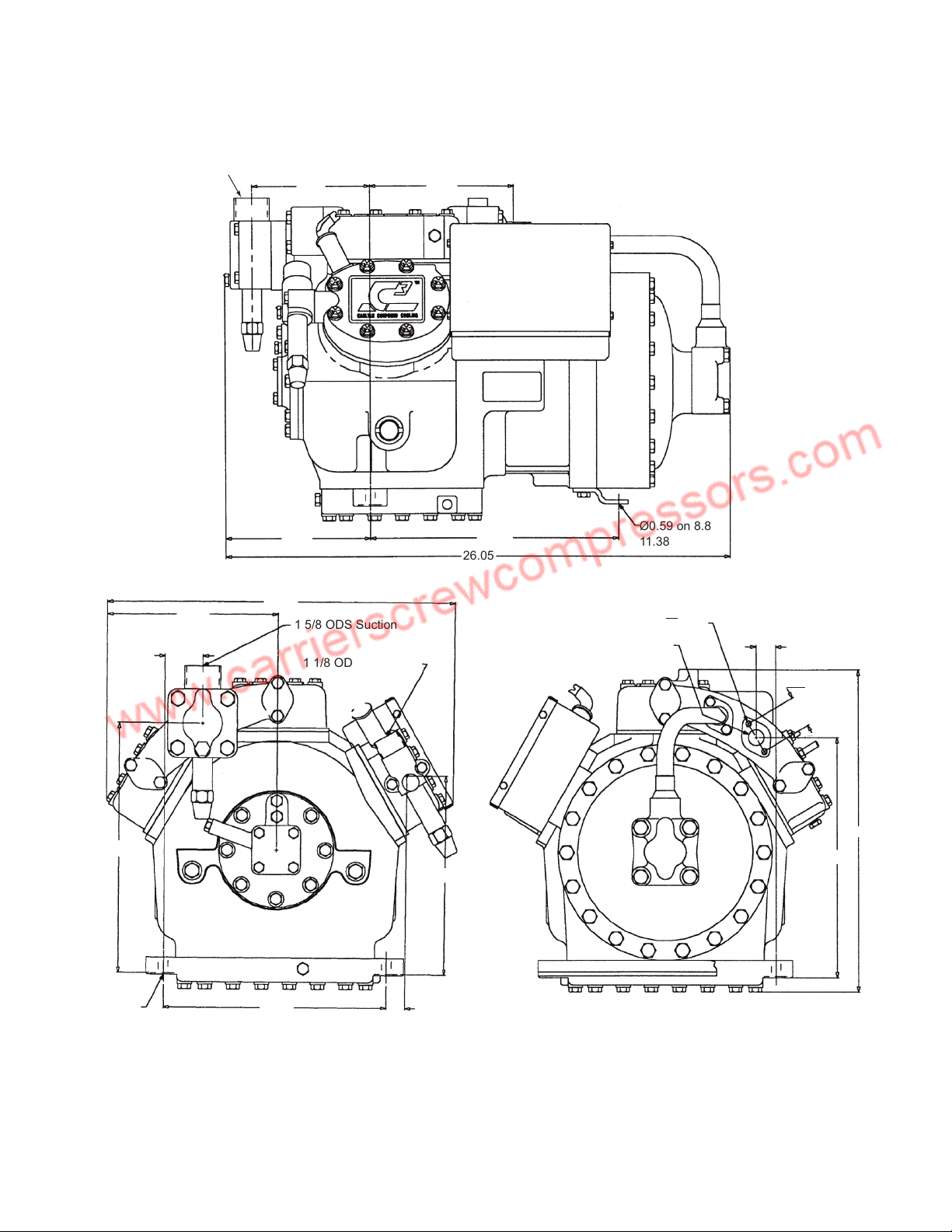

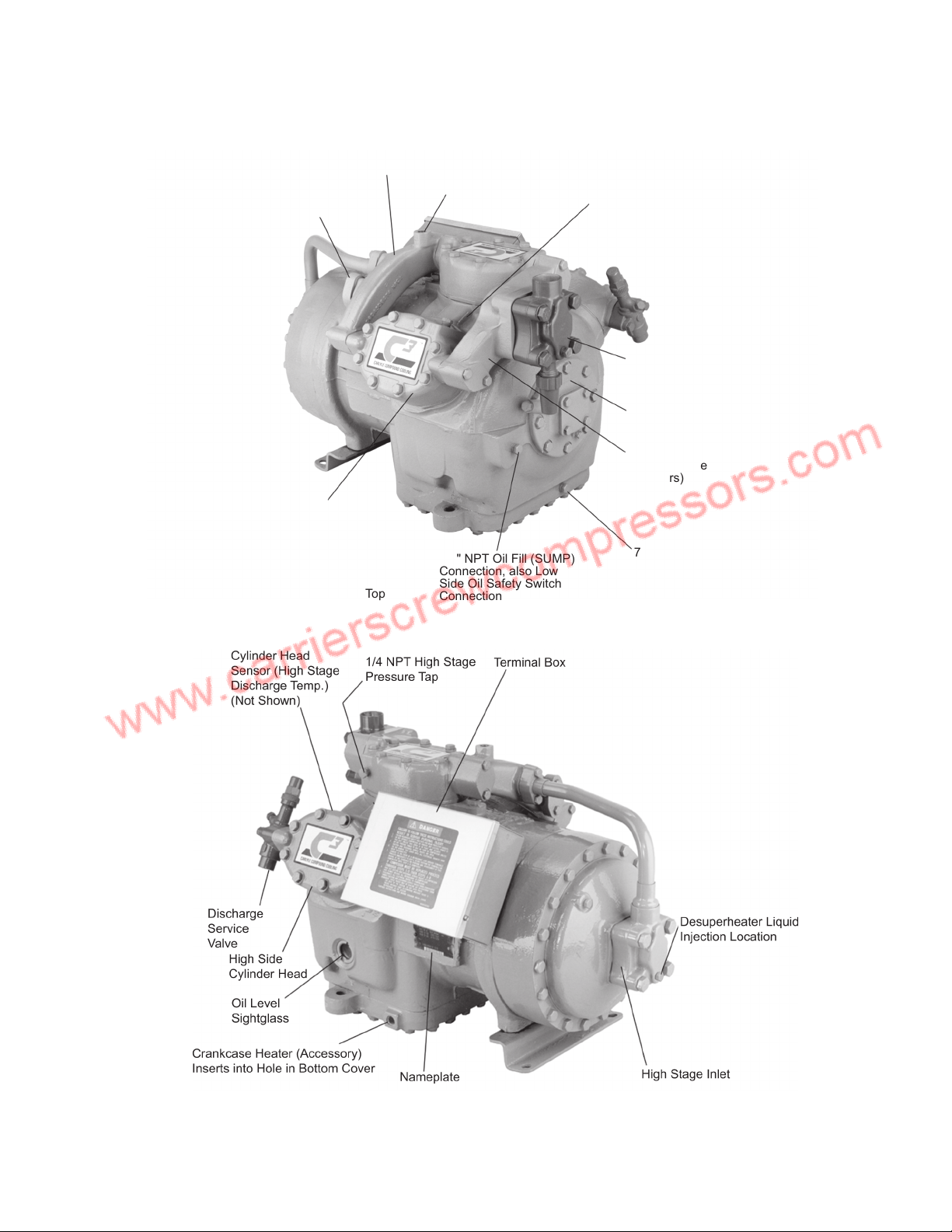

Compressor Physical Dimensions . . . . . . . . . . . 6-8

06CC Compressor (16 to 37 cfm) . . . . . . . . . . . . . 9

06CC Compressor (50 to 99 cfm) . . . . . . . . . . . . 10

1.0 System Design Considerations

1.1 Performance Data . . . . . . . . . . . . . . . . . . 11-13

1.2 Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3 Agency Approvals . . . . . . . . . . . . . . . . . . . . . 15

1.4 Circuit Breaker Selection Table . . . . . . . . . . . 15

1.5 Refrigerants . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.6 Electrical Data Table . . . . . . . . . . . . . . . . . . . 16

1.7 Subcoolers . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.8 Subcooler Selection . . . . . . . . . . . . . . . . . . . . 17

1.9 Subcooling Correction . . . . . . . . . . . . . . . . . . 19

1.10 Subcooler Load . . . . . . . . . . . . . . . . . . . . . . 19

1.11 Discharge Pressure Limits . . . . . . . . . . . . . . 19

1.12 Compressor Discharge Pressure Control . . 19

1.13 Variation in Capacity and Power . . . . . . . . . 19

1.14 Superheat Correction. . . . . . . . . . . . . . . . . . 19

1.15 Suction Line Accumulators. . . . . . . . . . . . . . 20

1.16 Single Compressors and Multiple Compressor

System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.17 Control Scheme . . . . . . . . . . . . . . . . . . . . . . 20

1.18 De-Superheating Expansion Valves. . . . . . . 20

1.19 Interstage Check Valves . . . . . . . . . . . . . . . 20

1.20 Capacity Control . . . . . . . . . . . . . . . . . . . . . 20

1.21 Low-Stage Discharge Gas Temperatures . . 20

1.22 Cylinder Head Cooling Fans . . . . . . . . . . . . 20

1.23 External De-Superheating . . . . . . . . . . . . . . 20

2.0 Compressor Lubrication System

2.1 Oil Separator and Oil Return . . . . . . . . . . . . .21

2.2 Oil Equalization. . . . . . . . . . . . . . . . . . . . . . . .21

2.3 Oil Pressure Safety Switch . . . . . . . . . . . . . . .21

2.4 Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

3.0 Refrigerant Control

3.1 Suction and Interstage Piping. . . . . . . . . . . . .22

3.2 Suction Line Sizing . . . . . . . . . . . . . . . . . . . . .23

3.3 Suction Pressure Range. . . . . . . . . . . . . . . . .23

3.4 Intermediate Pressure Range. . . . . . . . . . . . .23

3.5 Discharge Pressure Range. . . . . . . . . . . . . . .23

3.6 High-Low Pressure Switches . . . . . . . . . . . . .24

4.0 Compressor Features

4.1 Overtemperature Protection . . . . . . . . . . . . . .25

4.2 Overcurrent Protection . . . . . . . . . . . . . . . . . .25

4.3 Internal Pressure Relief Valves. . . . . . . . . . . .25

5.0 Compressor Wiring

Typical 06CC 16 to 37 cfm

Installation Wiring . . . . . . . . . . . . . . . . . . . . . . . . .26

Typical 06CC 50 to 99 cfm

Installation Wiring . . . . . . . . . . . . . . . . . . . . . . . . .27

6.0 Compressor Accessories. . . . .28-30

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Contents