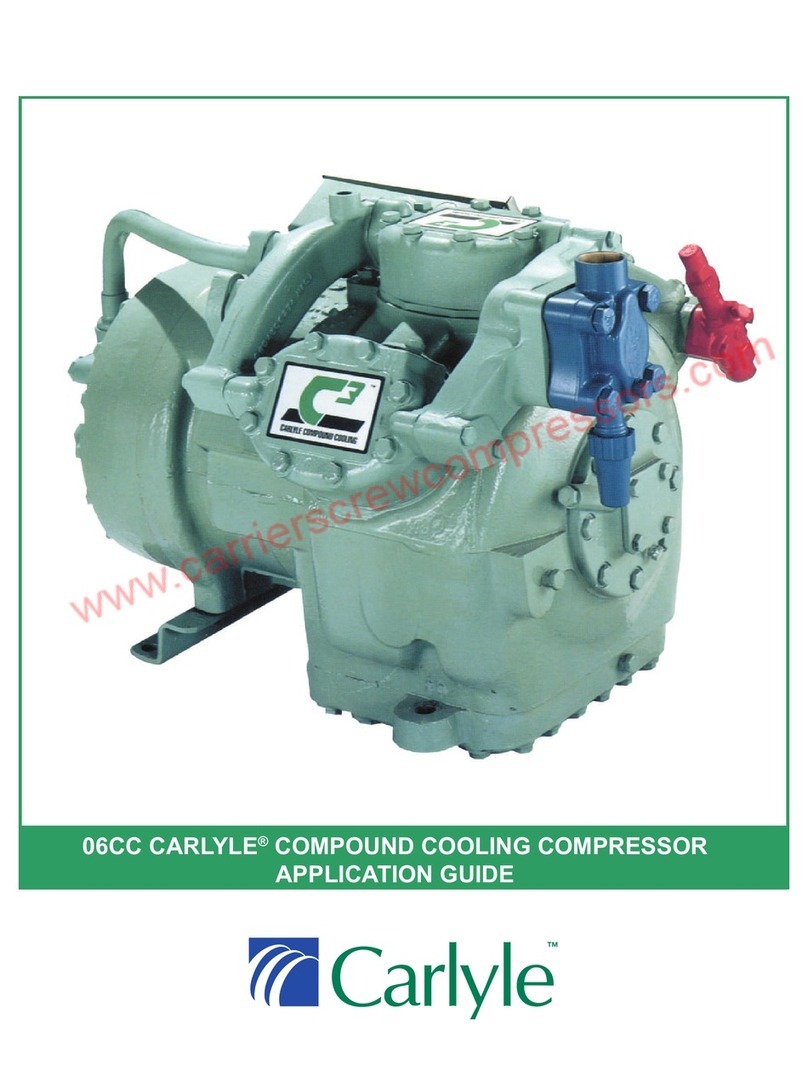

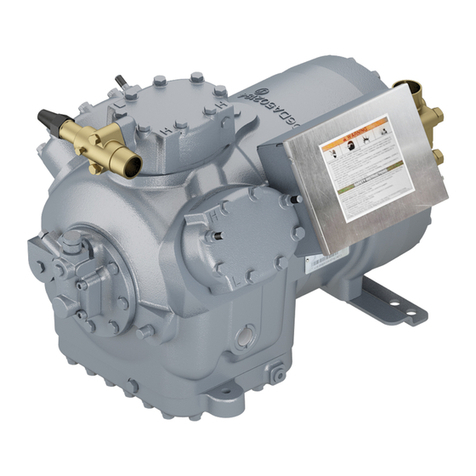

06CC COMPRESSORS

06CC 6 65 E 201

Design Variable:

101 = Single Pack, W/O Valves, with Oil

102 = Single Pack with Valves & Oil

103 = Single Pack, Service W/O Valves and Term. Box or Oil

201 = Single Pack, W/O Valves or Oil

202 = Single Pack with Valves

Electrical Characteristics:

A = 415-3-50, XL and PW

B = 415-3-50, XL

C = 415-3-50, PW

D = 208/230-3-60, XL

E = 208/230/400/460-3-50/60

F = 400/460-3-50/60, XL and PW

G = 400/460-3-50/60, XL

H = 400/460-3-50/60, PW

J = 575-3-60, XL and PW

K = 230-3-60, PW

L = 220-3-50, XL and PW

M = 220-3-50, XL

N = 220-3-50, PW

P = 220/346/380-3-50/60, XL and PW

Displacement(in Cfm at 1750 rpm) (See Note below)

Motor Size and Protection:

0 = 15 FT-LB / 5 HP

A = 15 FT-LB / 5 HP

B = 15 FT-LB / 5 HP

C = 15 FT-LB / 5 HP

1 = 20 FT-LB / 6.5 HP

D = 20 FT-LB / 6.5 HP

E = 20 FT-LB / 6.5 HP

F = 20 FT-LB / 6.5 HP

2 = 24 FT-LB / 7.5 HP

G = 24 FT-LB / 7.5 HP

H = 24 FT-LB / 7.5 HP

J = 24 FT-LB / 7.5 HP

3 = 24 FT-LB / 7.5 HP

K = 24 FT-LB / 7.5 HP

L = 24 FT-LB / 7.5 HP

M = 24 FT-LB / 7.5 HP

5 = 45 FT-LB / 15 HP

6 = 60 FT-LB / 20 HP

7 = 75 FT-LB / 25 HP

8 = 90 FT-LB / 30 HP

Compressor Type:

06CC = Compound Cooling Model

06CY = Service Compressor

06C8 = Compressor, Special

NOTE: USE OF “Cfm” AS MODEL SIZE DESIGNATION

Carlyle uses the “Cfm” designation in the model number to identify the compressor size. The Cfm values are the sixth and

seventh digits of the model number. See example above. Carlyle offers two series of compressors based on body size.

The smaller compressors, from 8 to 37 Cfm, are referred to as “D” size units (model number “06D”). The larger

compressors, from 50 to 99 Cfm, are referred to as “E” size units (model number “06E”).

The 06CC, or Compound Cooling compressors, are made in 16 to 37 Cfm and 50 to 99 Cfm sizes.

The 16 to 37 Cfm compressors use “D” size bodies. The 50 to 99 Cfm compressors use “E” size bodies.

NOTE: METRIC MEASUREMENTS

The compressors are built using English units: inches, foot-pounds, pints, etc. A corresponding metric measurement

has been added to all the English units in this guide. These metric measures are a guide only, having been rounded

to the nearest whole number, and therefore are not meant to be an exact mathematical conversion.

S = Oil Sensor Block and OPSS sensor (shown as the 10th digit)

Information in shaded area is no longer available in standard factory production.

5th Digit Motor Size Overload Variable

Electromechanical Overcurrent Protection (*No Longer Available)

115/240V Control Voltage, Electronic Overcurrent Protection

24V AC Control Voltage, Electronic Overcurrent Protection

24V DC Control Voltage, Electronic Overcurrent Protection

Electromechanical Overcurrent Protection (*No Longer Available)

115/240V Control Voltage, Electronic Overcurrent Protection

24V AC Control Voltage, Electronic Overcurrent Protection

24V DC Control Voltage, Electronic Overcurrent Protection

Electromechanical Overcurrent Protection (*No Longer Available)

115/240V Control Voltage, Electronic Overcurrent Protection

24V AC Control Voltage, Electronic Overcurrent Protection

24V DC Control Voltage, Electronic Overcurrent Protection

Electromechanical Overcurrent Protection (*No Longer Available)

115/240V Control Voltage, Electronic Overcurrent Protection

24V AC Control Voltage, Electronic Overcurrent Protection

24V DC Control Voltage, Electronic Overcurrent Protection

Not Factory Installed, External Overcurrent Protection Required

Not Factory Installed, External Overcurrent Protection Required

Not Factory Installed, External Overcurrent Protection Required

Not Factory Installed, External Overcurrent Protection Required

Q = 380-3-60, XL