3

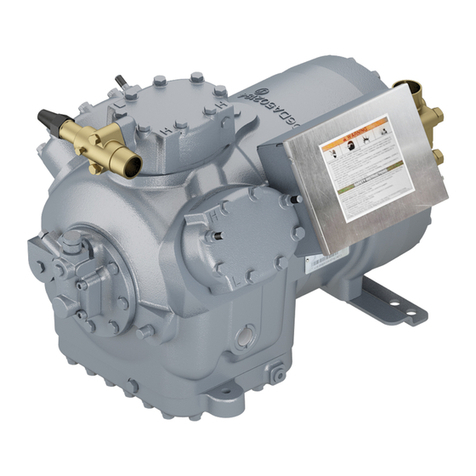

This manual is for the Carlyle®Paragon screw compres-

sor product line, which is comprised of four unique com-

pressor families (series type TS, TT, TU, and TV). Carlyle

offers distinct versions of the Paragon Twin-Screw Com-

pressors for Low/Medium/High Temperature applications.

The operational limits, required accessories, and opera-

tional guidelines are contained in this manual and must

be complied with to stay within the compressor warranty

guidelines.

R-134a, R-513A, R-1234ze Applications

The TS series compressors are designed for air-cooled

applications only. The TT, TU, and TV series compres-

sors are available in both air-cooled and water-cooled

applications. There are 3 different displacement sizes of

each of the TS, TT, and TV series compressors, along

with 2 displacement sizes of the TU series compressor.

Each Paragon twin-screw compressor is designed to be

applied with a dedicated, performance-matched oil sep-

arator. Carlyle offers two types of oil separators: high-effi-

ciency (for applications in flooded-type systems) and

standard-efficiency (for application in direct expansion-

type systems). This compressor / oil separator assembly

is then applied in a single-compressor, medium-tempera-

ture, or high-temperature refrigeration circuit. Carlyle

offers the required oil separators as shown in Section 9.1

of this application guide. See Section 10.5 of this docu-

ment for Assembly views of the R-134a Paragon models

applied with these oil separator designs. Application

guidelines for the R-134a compressors that have been

approved for VFD applications are covered in this guide.

R-404A, R-407A, R-407C, R-407F, R-448A,

R-449A, and R-507A Applications

The low/medium temperature Paragon twin-screw com-

pressor models are designed to be applied in single or

multiple compressor circuits. Each circuit requires a prop-

erly selected oil separator (contact Carlyle Application

Engineering for selection criteria). Carlyle offers 3 models

within each of the TS and TT compressor series for low/

medium temperature applications.

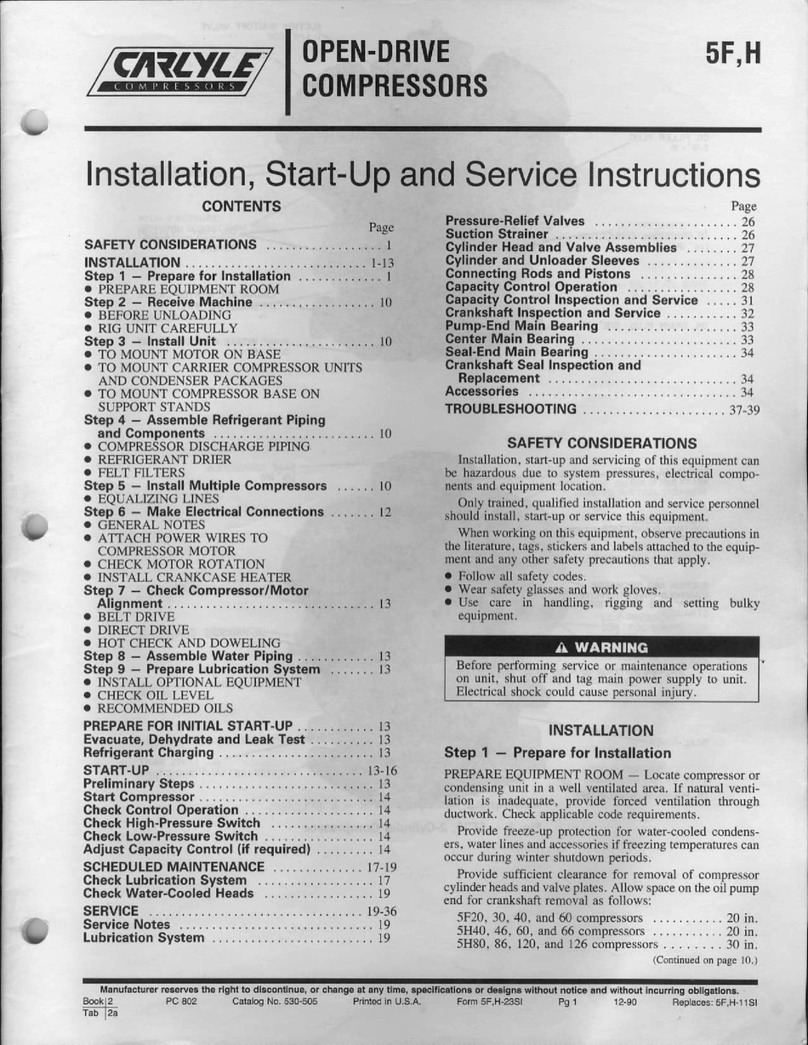

Scope

This application guide is intended to familiarize system

designers with the Paragon screw compressor and to

provide technical information necessary to assure safe

and reliable compressor operation.

Certifications

UL and CSA approvals have been obtained for specific

06TS, 06TT, 06TU, and 06TV screw compressor models

applied with R-134a and for certain 06TS and 06TT

screw compressor models applied with R-404A, R-407A,

R-407C, R-407F, and R-507A (compressors that have an

R or M in the fifth digit of the model number).

UL File #: SA4936 CSA File #: SA4936

For the UL and CSA approvals it is essential that only

Listed, Special-Purpose circuit breakers or Carlyle

approved, solid-state motor overloads be used (contact

Carlyle Application Engineering for further information).

For circuit breakers, the Must Trip Amp settings must not

exceed 140% of the compressor rated load amps.

Both UL and CSA approvals have been obtained for all

voltage combinations shown in Section 8.3 of this guide.

These compressor models also comply with the EC Low

Voltage and Machinery Directives.

Compressor Offerings

The four Paragon compressor frame sizes (TS, TT, TU,

and TV) are optimized for application in economized

refrigeration circuits. Non-economized capacity will

decrease by 11 to 16% for water-cooled operation. The

following tables show the displacements for each of the

compressors at 60 Hz.

Compressor Displacement (R-134a, R-513A,

R-1234ze for air and water cooled models)

See Tables 1 and 2.

Table 1 — Air-Cooled Models

Table 2 — Water-Cooled Models

NOTE: Carlyle has optimized the Vi (volume index) for

the R-134a air-cooled and water-cooled models.

MODEL

NUMBER

NOMINAL

HORSEPOWER

DISPLACEMENT

(CFM at 60 Hz)

06TSA137 60 137

06TSA155 75 155

06TSA186 75 186

06TTA266 120 266

06TTA301 150 301

06TTA356 150 356

06TUA483 225 483

06TUA554 225 554

06TVA680 340 680

06TVA753 340 753

06TVA819 340 819

MODEL

NUMBER

NOMINAL

HORSEPOWER

DISPLACEMENT

(CFM at 60 Hz)

06TTW266 90 266

06TTW301 90 301

06TTW356 120 356

06TUW483 160 483

06TUW554 160 554

06TVW680 225 680

06TVW753 225 753

06TVW819 225 819

Introduction