GENERAL

1. Inspect compressor for shipping damage and file claim with ship-

ping company if damaged or incomplete.

2. Check compressor nameplate for correct model and voltage

designation.

3. Before installation, review all Carlyle compressor application litera-

ture to assure yourself that the proper compressor has been selected

and is being applied in a proper manner. The required application

literature is available through Carlyle.

4. To facilitate customer installation requirements, the following parts

are factory supplied in a separate parts bag located in the compres-

sor terminal box:

PART NUMBER DESCRIPTION QUANTITY

06EA500551 Jumper Bar (2 hole) 3

AT14QA241 Jam Nut 3/8 9

06EA502782 Jumper Bar (3 hole) 1

06EA402632 Tee Valve Assy. 1

574-068 Instruction Sheet 1

SAFETY INSTRUCTIONS

WARNING: Failure to follow these instructions could result in

serious personal injury.

1. Follow recognized safety procedures and practices.

2. Do not remove any compressor bolts or fittings until factory-

supplied holding charge has been relieved. Exhaust holding charge

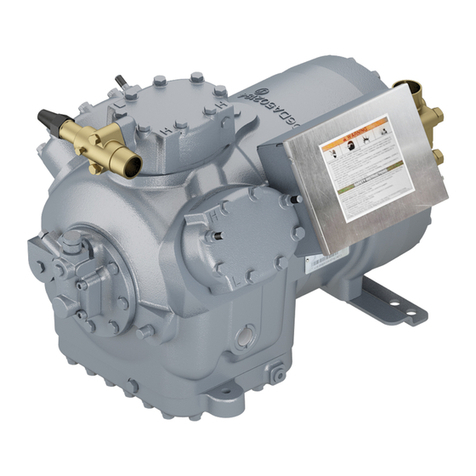

pressure through low-pressure connection (shown in Figs. 1 & 2) by

removing the connection cap and depressing the internal disc.

3. Do not apply any power to the compressor unless suction and

discharge service valves are installed and opened.

4. Do not operate or provide any electrical power to the compressor

unless the terminal box cover is in place and secured. Measurement

of amps and volts during running conditions must be taken at other

points in the power supply.

5. Do not remove terminal box cover until all electrical sources have

been disconnected.

6. Follow recommended safety precautions listed on termi-

nal box cover label before attempting any service work on the

compressor.

GENERAL INSTALLATION PROCEDURES

Holding Charge

Compressor is factory supplied with a 5 to 15 psig (1.4 to 2 bar)

charge of dry air. This internal pressure must be relieved before at-

tempting to remove any compressor fitting or part.

Relieve holding charge by removing the cap on the low pressure

connection fitting and depressing the internal disc. See Figs. 1 & 2

for applicable low pressure connection fitting location.

Service Valves

Remove valve pads and attach factory supplied suction and discharge

gaskets and service valves to the compressor. Torque applicable

service valve mounting bolts as noted:

Bolt Size Torque lb-ft (N-m)

5/16 - 18 19 - 23 (25.7 - 31.1)

1/2 - 13 80 - 90 (108 - 122)

5/8 - 11 90 - 120 (122 - 163)

When brazing piping to valve, disassemble valve or wrap in a wet cloth

to prevent heat damage.

Oil

1. Check to see that oil level is 1/8 to 3/8 way up on compressor

sightglass before starting and after 15 to 20 minutes of operation.

Compressors may be shipped with or without an oil charge based on

model. All compressors must contain the specified oil charge prior to

start up as a condition of warranty.

CAUTION: Oil levels on 06E compressors should not be allowed

to go above the center of sightglass. High oil levels require

excess power and shorten compressor life.

2. To add oil: Relieve internal crankcase pressure, isolate crankcase,

and add oil through the oil fill connection (see Figs. 1 & 2).To remove

excess oil: Reduce internal crankcase pressure to 2 psig (1.15 bar),

isolate crankcase then loosen the oil drain plug allowing oil to seep

out past the threads of the plug.

CAUTION: With the compressor crankcase under slight pres-

sure, do not remove the oil drain plug as the entire oil charge

could be lost. Do not reuse drained oil or oil that has been

exposed to the atmosphere.

3. When additional oil or a complete oil change is required, use only

the listed Carlyle approved oils.

For CFC and HCFC refrigerants use:

Manufacturer Brand Name

Totaline 150

Witco Suniso 3GS

Shrieve Chemical Zerol 150

Texaco Ind. WFI-32-150

IGI Petroleum Ind. Cryol-150

For HFC refrigerants use:

Manufacturer Brand Name

ICI EMKARATE RL68H

*Lubrizol Lubrikuhl 2916S

**Mobil Arctic EAL 68

**Castrol SW 68

Castrol E 68

Totaline P903-1701

*Lubrizol ISO 68 also sold under Texaco Capella HFC 68NA brand.

**Medium and high temperature applications only.

ELECTRICAL

General

Consult the wiring diagram located inside the compressor terminal

box cover and Figure A for wiring connection locations.

Installation and

Start-Up Instructions 06E

™