(SHEET 1 OF 2)

IS1949A(09/22)

URBANE II HOB SENSOR SOAP DISPENSER

INSTALLATION INSTRUCTIONS

*

*

Important Information

*

Both water based & non-water based soap solutions can be used.

Soap solution viscosity should be within 100 to 2500 cps.

For high viscosity soap solutions, the foam level knob (30) must be

set to minimum at '-' no air to enable smooth dispensing.

For water based solutions, the foam level knob (30) must be turned

anti-clockwise towards '+' max. air.

Soap control unit must be primed before first use and after every

refill. Follow priming instructions, as shown in Fig.1.

The soap control unit (12) is mains powered only. Separate

battery box is supplied which can be used as a battery

backup.

Installation

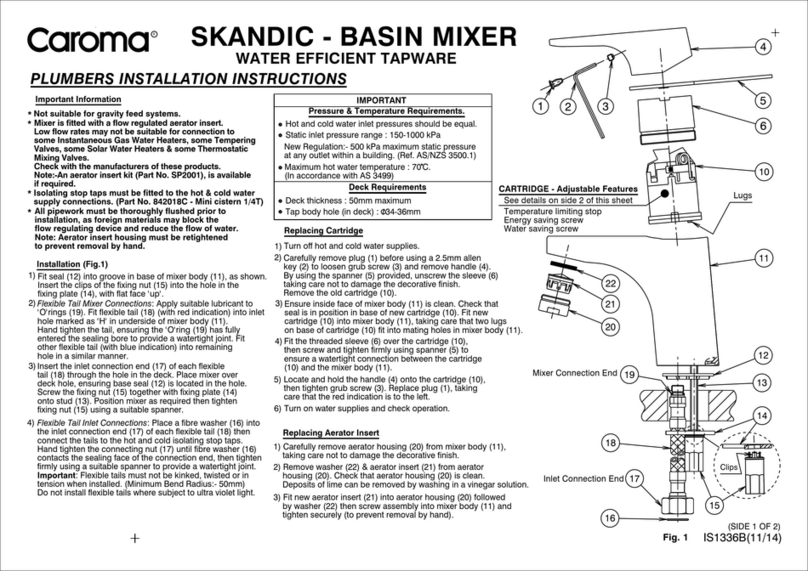

1) Ensure 'O'ring (1) is fitted into groove in base ring (2).

2) Insert the soap tube (3), air tube (4) and sensor cable (5) through the

hole of base ring (2). Pass base ring (2) through threaded tube (7)

until the base ring (2) sits against bottom of sensor body (6).

3) Insert soap tube (3), air tube (4) and sensor cable (5) through the hole

in the deck. Insert threaded tube (7) into deck hole, orientate sensor

body as required. From under the deck, Insert soap tube (3), air tube (4)

and sensor cable (5) through flat seal (8), washer (9) and clamp ring (10)

in order, then fit flat seal (8) followed by washer (9) over threaded tube (7)

as shown in Fig. 2. Screw clamp ring (10) onto threaded tube (7) until it

contacts washer (9) & the flat seal (8) has contacted the underside of the

deck. Tighten two screws (11) equally until sensor assembly is clamped

firmly to the deck. DO NOT OVERTIGHTEN.

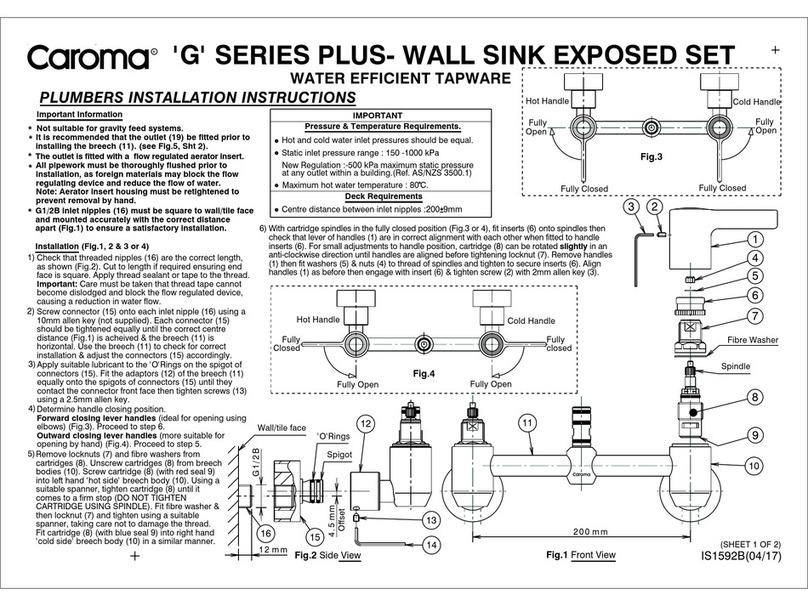

4a) Soap control unit installation (Fixed Mounting):

For installation into solid walls; (brick, concrete etc.)

i) Drill two 6mm holes, 40mm deep and 104mm apart horizontally as

shown in Fig. 3.

ii)Insert small end of wall plugs (15) into drilled holes and tap until flush

with wall/tile face.

iii)Align the slots on fixing plate (14) with the holes on the wall, pass the

screws (13) through the slots and insert into the wall plugs (15). Then

tighten the screws. DO NOT OVERTIGHTEN.

For installation into timber stud:

i) Drill two holes at 104mm apart horizontally to suit the self tapping

screws supplied as shown in Fig. 3.

ii)Align the slots on fixing plate (14) with the holes on the wall, pass the

screws (13) through the slots and insert into the holes in the stud. Then

tighten the screws. DO NOT OVERTIGHTEN.

Fill full soap into bottle (16), then screw soap bottle (16) into the soap

control unit (12).

6) Connections :

a) Soap tube and air tube connections, (Fig. 2 & Fig. 5):

Identify the embossings "SOAP" & "AIR under the soap unit (12).

Press clip (20), slide the clip down the tube labelled "SOAP". Fit

soap tube (3) onto the boss next to embossing "SOAP". Slide the clip

up over the tube (3) and ensure clip (20) is fitted onto groove of the

boss to prevent soap tube from being removed. In the same way,

fit air tube labelled as "AIR" (4) onto the boss next to embossing "AIR".

b) Sensor cable connection, (Fig.2):

By aligning the profile of connectors (5) & (17), connect the sensor

cable (5) from the outlet to the end of sensor cable (17) of soap control

unit as shown in Fig. 2.

c) Power cable connection:

While aligning the 'D' profile of male and female connectors

Connect male connector of power cable (22) to female connector (18)

of soap control unit (12) as shown in Fig. 2. Connect male connector(19)

from control unit (12) to female connector (27) of battery box (26).

Ensure all cable connectors are pushed in fully.

Insert/replace 4 x 1.5V 'D' batteries following the "-" & "+" markings.

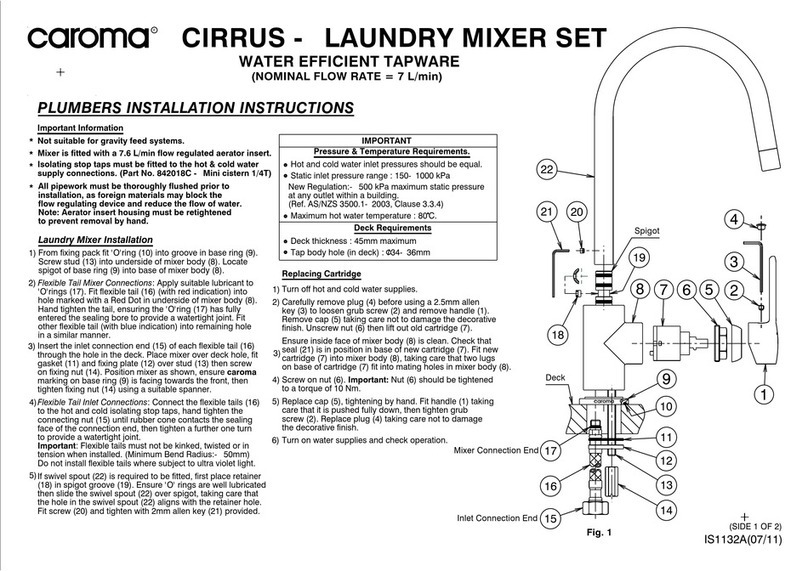

2)

1) Remove screws (32) using a phillips head screw driver then

put the screws aside, remove the cover of battery box.

7) Adding/Replacing batteries, (Fig. 6)

3)

Fit the cover back on ensuring the seal is in place and compressed.

4)

The flat head screwdriver can be used in the battery box to prise the

cover open.

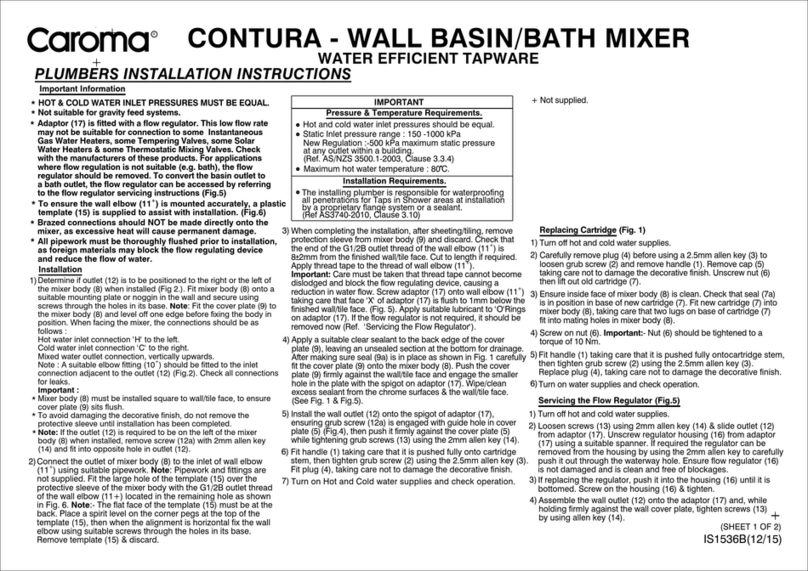

4b) Solenoid Control box installation (Removable):

Optional removable bracket (supplied) allows the control box to be

lifted off quickly for easy access to solenoid and remove bottle.

i) Remove the screws (28) using a phillips head screw driver.

ii) Remove the wider fixing plate (14) and put it aside.

iii)Take the narrower fixing plate (29) out of the bag, fit it at the back of

the control box (12) by aligning the holes on the fixing plate (29) with

the holes at the back of the control box (12). The cut-outs on the plate

should be towards the bottom, as shown in Fig.7.

iv) Fit the screws (28) and tighten, DO NOT OVERTIGHTEN.

For installation into solid walls; (brick, concrete etc.)

i) Drill two 6mm holes, 40mm deep and 52mm apart horizontally as

shown in Fig. 7.

ii)Insert small end of wall plugs (15) into drilled holes and tap until flush

with wall/tile face.

iii)Insert screws (13) into wall plugs, screw them until the head is 6mm

away from wall/tile face as shown in Fig. 7.

iv)Mount the control box (12) onto the screws (13).

For installation into timber stud or MDF boards:

i) Drill two holes at 52mm apart horizontally to suit the self tapping

screws supplied as shown in Fig. 7.

ii)Insert screws (13) into the holes, screw them until the head is 6mm

away from wall/tile face as shown in Fig. 7.

iii)Mount the control box (12) onto the screws (13).

5) Battery box installation :

For installation into solid walls; (brick, concrete etc.)

i) Drill two 6mm holes, 40mm deep and 22mm apart vertically

as shown in Fig. 6.

ii) Insert small end of wall plugs (23) into drilled holes and tap until

flush with wall/tile face.

iii)Align the slots on bracket (24) with the holes on the wall, pass the

screws (25) through the slots and insert into the wall plugs (23).

Then tighten the screws DO NOT OVERTIGHTEN.

iv)Mount the battery box (26) onto wings of bracket (24).

For installation into timber stud or MDF boards:

i) Drill two holes at 22mm apart vertically to suit the self tapping

screws supplied as shown in Fig. 6.

ii)Align the slots on bracket (24) with the holes on the wall, pass the

screws (25) through the slots and insert into the holes in the stud.

Then tighten the screws. DO NOT OVERTIGHTEN.

iii)Mount the battery box (26) onto wings of bracket (24).