I N S T R U C T I O N S

For the installation and maintenance of DC1525 - DC1550

desuperheaters

IMI0049E.doc

Rev.0 20/08/14

20090 SEGRATE (MI)- via E.Fermi

TEL.(02) 269912.1 - FAX.(02) 2692.2452

Page 2 of 16

MAIN INDEX

Pag.

1 General information ............................................................................................3

2 Guarantee ...........................................................................................................3

3 Validity of instructions..........................................................................................3

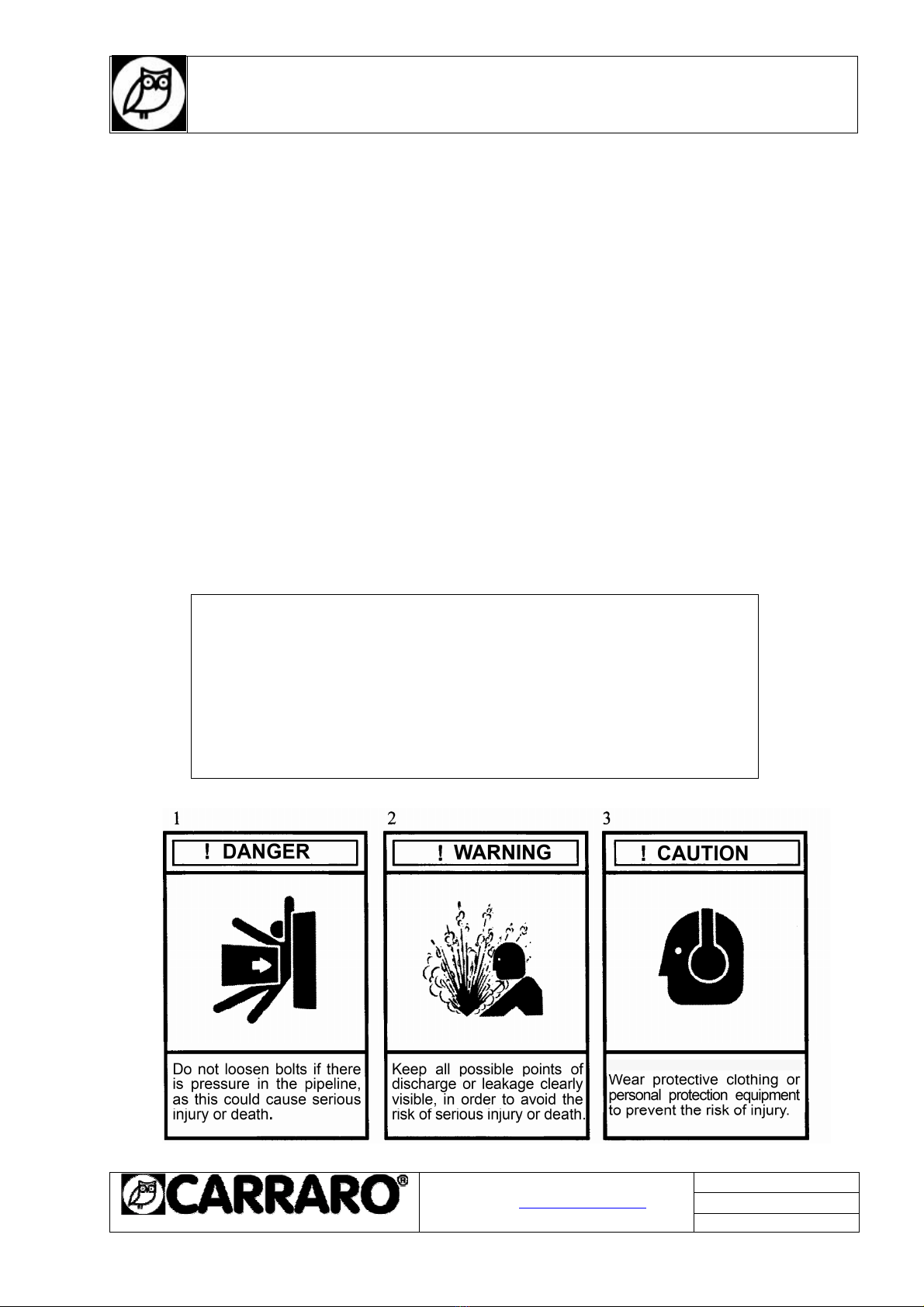

4 Safety indications.................................................................................................4

5 Safety warnings...................................................................................................5

6 Safety precautions...............................................................................................6

7 Transport, handling and storage..........................................................................7

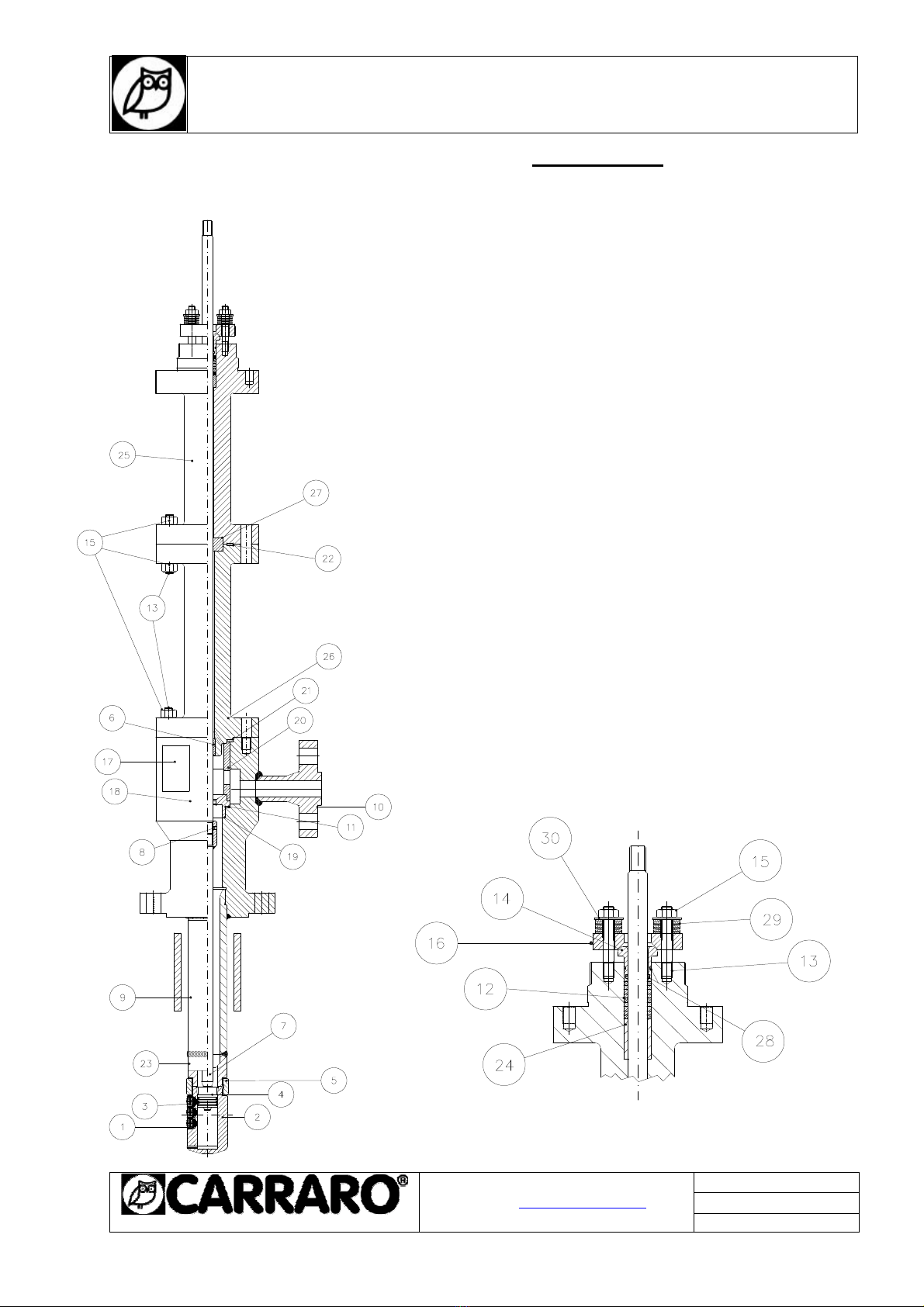

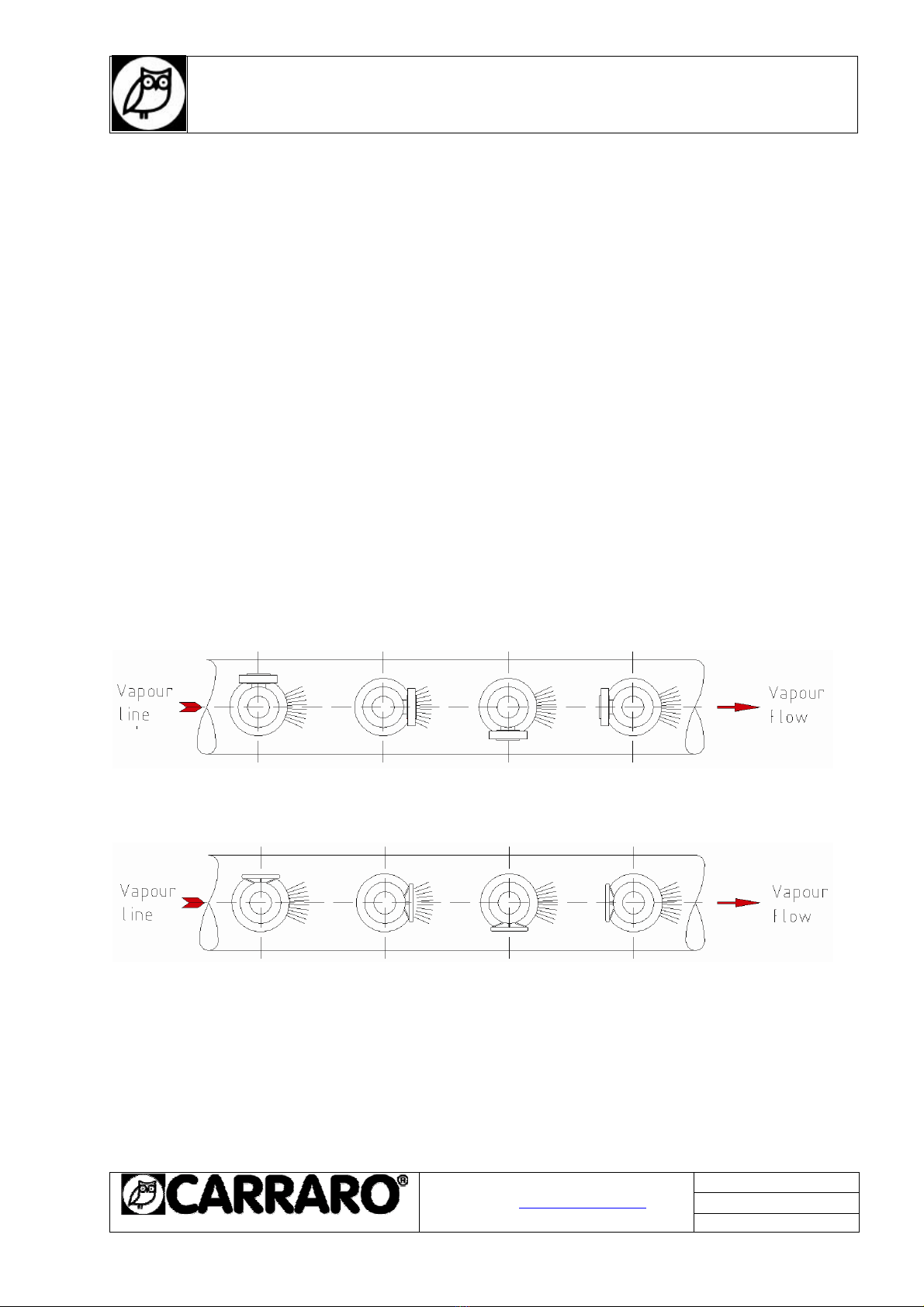

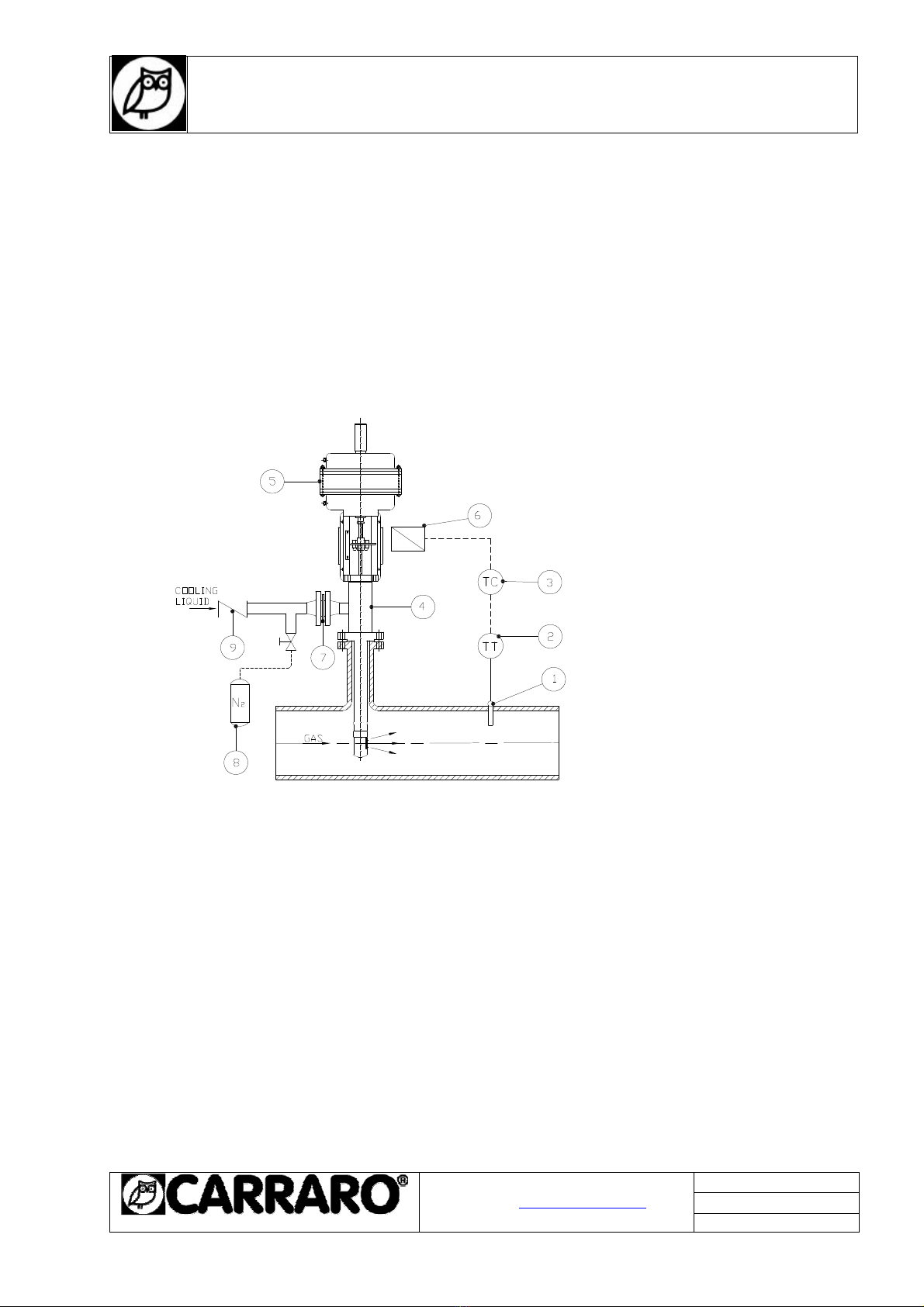

8 Inst. and ass. instructions for DC1525 - DC1550

8.1 Cross-section drawings .....................................................................................8

8.2 Removing the packaging ...................................................................................9

8.3 Installation.........................................................................................................9

8.4 Start-up..............................................................................................................12

9 Maintenance........................................................................................................12

9.1 Removal ..............................................................................................................13

9.2 Disassembly........................................................................................................13

9.3 Spray cylinder......................................................................................................13

9.4 Body extension....................................................................................................14

9.5 Piston assembly...................................................................................................14

9.6 Packing gland......................................................................................................14

9.7 Re-assembly........................................................................................................14

9.8 Welding................................................................................................................15

9.9 Re-installation......................................................................................................15

10 Replacement parts...............................................................................................16

10.1 Inspection procedure ...........................................................................................16

10.2 Storage................................................................................................................16

11 Repairs................................................................................................................17

1. GENERAL INFORMATION: