62-69137-00 7

pictograms available in Carrier network.

d. If a component having a pictogram is replaced by a

new one, be sure that the new component has the right

pictogram.

e. Place a warning pictogram by applying it on a dry

surface. Press to external sides to eliminate air

bubbles.

3. PRODUCT LOADING

Proper air circulation in the insulated box, air that can

move around and through the load, is a critical

element in maintaining product quality during

transport. If air cannot circulate completely around the

load: hot spots or top-freeze can occur.

The use of pallets is highly recommended. Pallets,

when loaded so air can flow freely through the pallets

to return to the evaporator, help protect the product

from heat passing through the floor of the truck. When

using pallets, it is important to refrain from stacking

extra boxes on the floor at the rear of the truck,

because this will cut off the airflow.

Product stacking is another important factor in

protecting the product. Products that generate heat,

fruits and vegetables for example, should be stacked

so the air can flow through the product to remove the

heat; this is called "air stacking" the product. Products

that do not create heat, meats and frozen products,

should be stacked tightly in the centre of the box.

All products should be kept away from the sidewalls

of the body, allowing air to flow between the body and

the load; this prevents heat filtering through the walls

from affecting the product.

It is important to check the temperature of the product

being loaded to ensure that it is at the correct

temperature for transport. The refrigeration unit is

designed to maintain the temperature of the product at

the temperature at which it was loaded; it was not

designed to cool a warm product.

SOME ADVICE

Before loading

• Pre-cool the inside of the insulated body by lowering

the temperature for about 15 minutes.

• Evacuate the humidity existing inside the box by

carrying out a manual defrost. For CITIMAX500/700

units, the defrost mode can only take place when the

box temperature lower than 4°C.

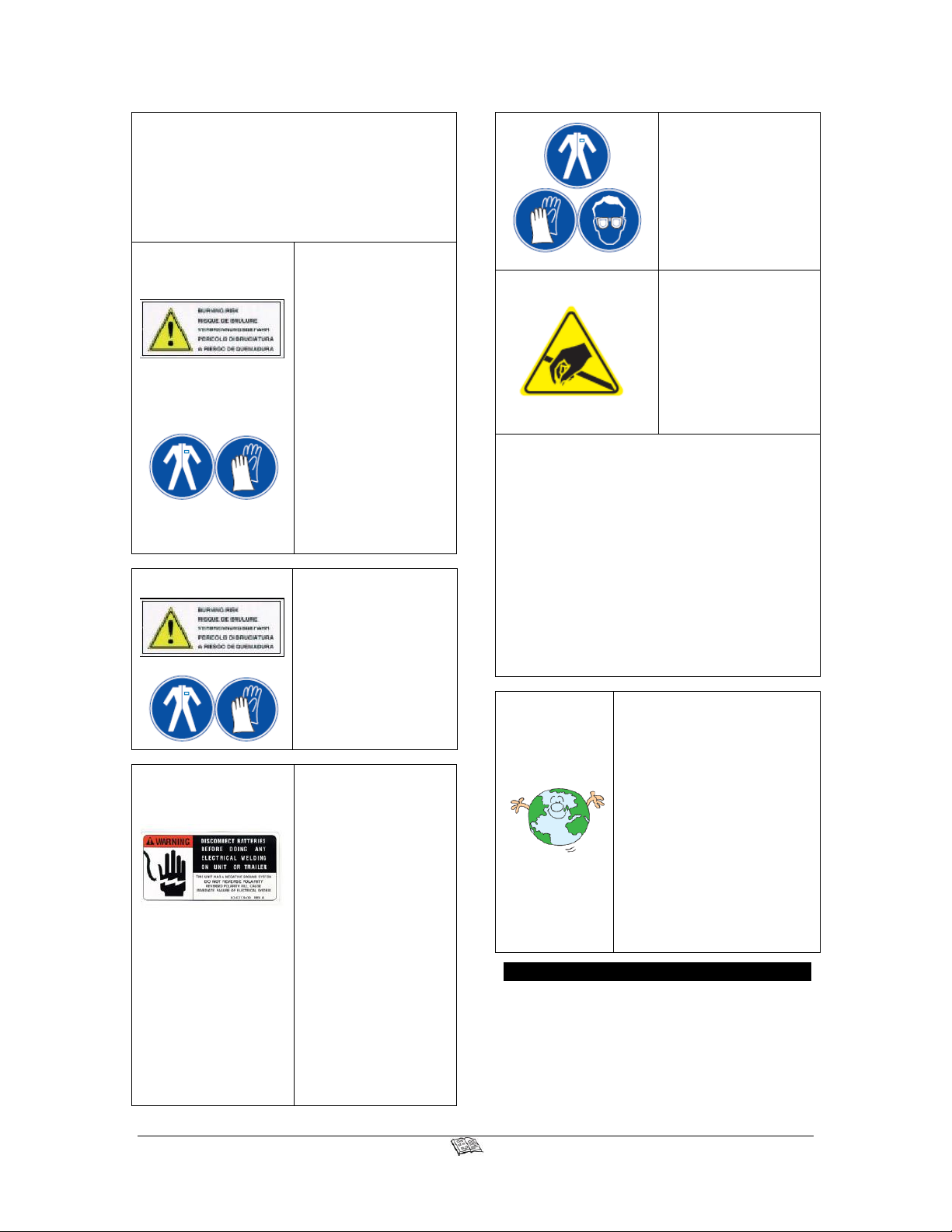

• Evaporator fans are protected by safety grills. In the

event of heavy duty use of the unit, ice can accumulate

on the grills. It is therefore recommended to clean

them regularly by means of a small brush. The

operation MUST be done when the unit has been

SHUT DOWN.

When loading

• To be carried out with the unit stopped.

• It is recommended to open doors as little as possible

to avoid the intake of hot air and humidity.

• Select the temperature by means of the thermostat,

according to the transported goods.

• Check the internal

temperature of the goods

being loaded (using a probe

thermometer).

• Take care not to obstruct

the air intakes on the

evaporator section and the

ventilation ducts.

Load spacers

Load on pallets

• Leave a free space of about :

- 6 to 8 cm between load and front wall,

- 20 cm between the top of the load and the roof,

- between the floor and the load (gratings, pallets).

• Do not forget to close the doors.

• Before closing the doors, check your load once more

and see that nobody is

shut inside the box.

NOTE :

For stationary

utilization, we

recommend to place the

body in the shade.