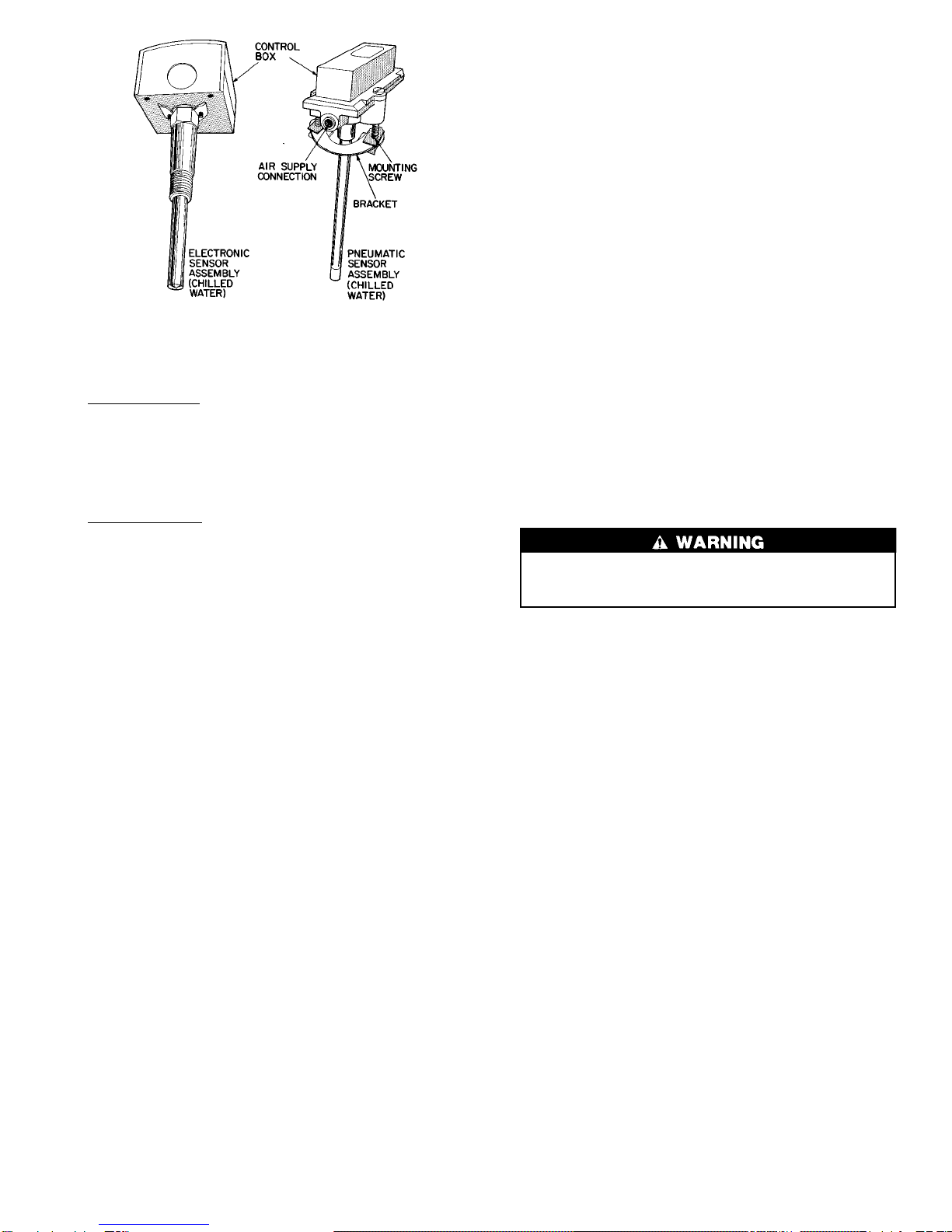

INTRODUCTION

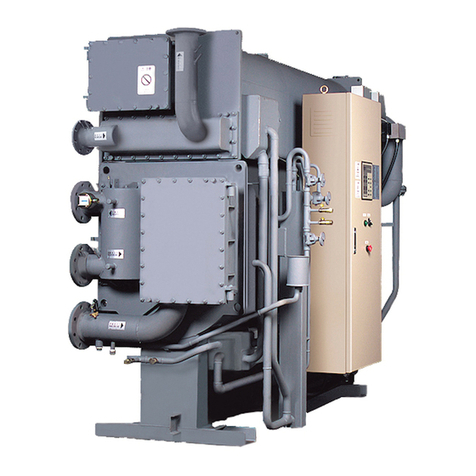

General— The 16JB machine is factory assembled, wired

and leak tested. Installation (not by Carrier) consists prima-

rily of establishing water and electrical services to the ma-

chine. Rigging, installation, field wiring and field piping are

the responsibility of the contractor and/or customer. Carrier

has no installation responsibilities for the equipment. The

scope of Carrier’s duties at time of start-up are listed in In-

troduction portion of the 16JB Start-Up, Operation and Main-

tenance Instructions.

Job Data — Necessary information consists of: Machine

location drawings, piping drawings, field wiring diagrams

and rigging guide.

RECEIVING AND INSTALLATION

Step 1 — Check Equipment

IDENTIFY MACHINE — The machine model number and

serial number are stamped on machine identification plate.

Check this information against shipping papers and job data.

INSPECT SHIPMENT — The machine is at a deep

vacuum when shipped. Do not open any valves until the vacuum

has been noted. Refer to Shipping Vacuum Check.

Inspect for shipping damage while machine is still on ship-

ping conveyance. If machine appears to be damaged or has

been torn loose from its anchorage, have it examined by trans-

portation inspectors before removal. Forward claim papers

directly to transportation company. Manufacturer is not re-

sponsible for any damage incurred in transit.

Check all items against shipping list. Immediately notify

the nearest Carrier Air Conditioning office if any item is

missing.

To prevent loss or damage, leave all parts in original pack-

ages until installation.

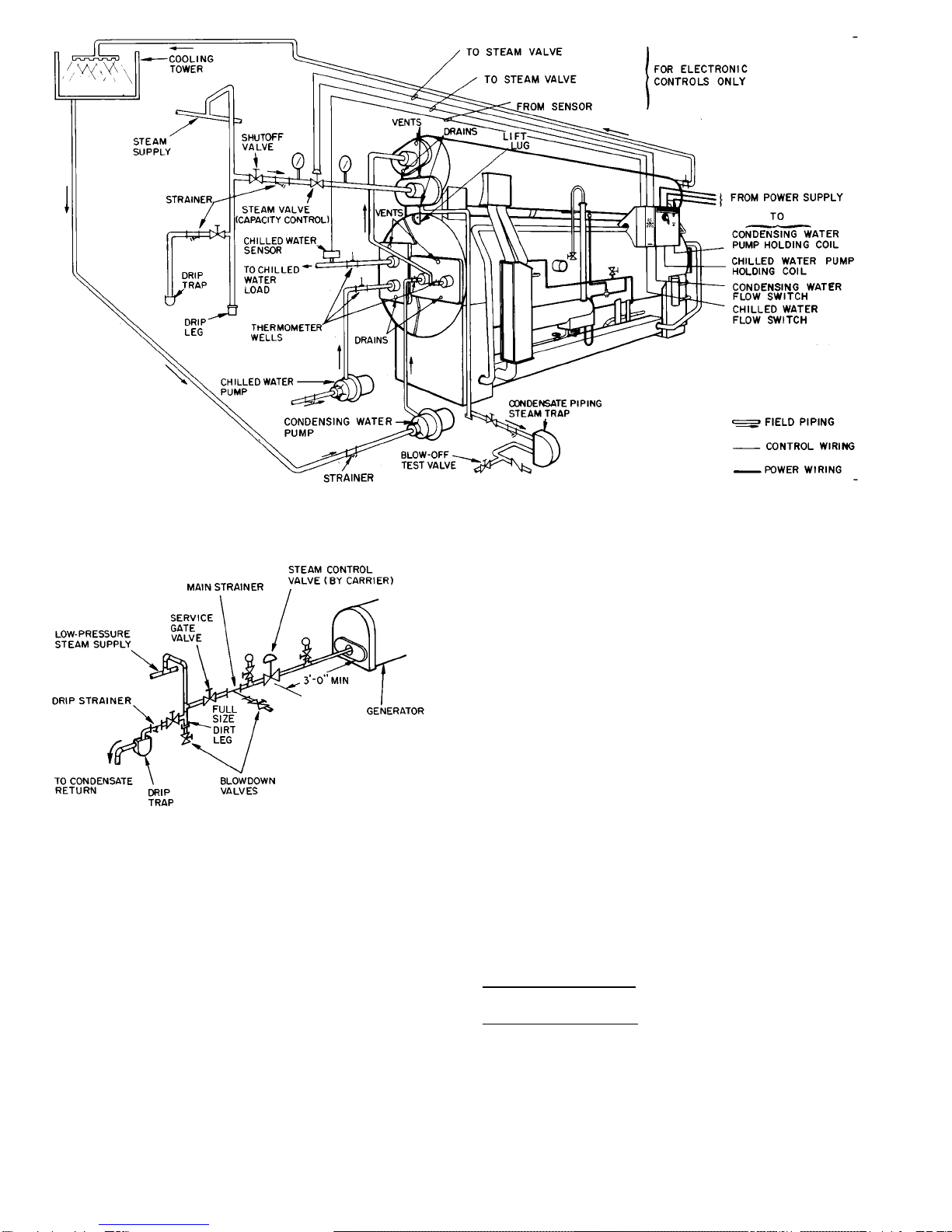

CHECK SHIPPING VACUUM — To check for leaks that

have occurred during shipment:

a. Connect an absolute pressure gage to places listed in

Table 1.

b. Record the absolute pressure of each assembly. If ves-

sel pressure is greater than 0.28 in. (7mm) of mercury,

the machine has acquired a leak in shipping, and must

be leak tested. Refer to the Machine Leak Test proce-

dure for instructions.

Table 1 — Absolute Pressure Gage

Test Connections

UNIT

16JB GAGE CONNECTION

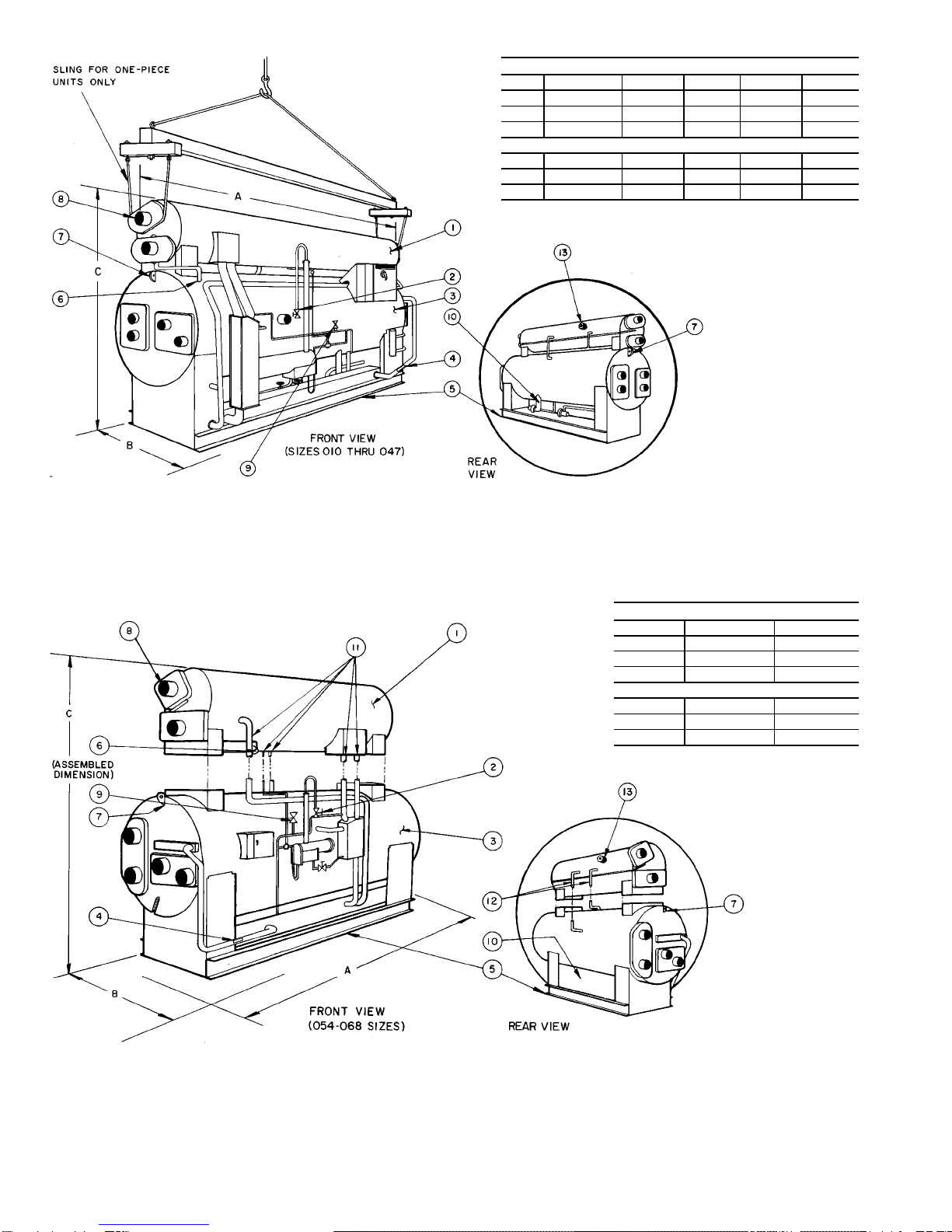

010-047 At auxiliary evacuation valve (item 9, Fig.1)

054-068

Generator-Condenser: At condenser-purge

suction line (Fig. 2)

Absorber-Evaporator: At auxiliary evacuation

valve (item 9, Fig. 1)

STORAGE PROTECTION — If the machine is not going

to be installed immediately, it is very important to use a drop

cloth or plastic covering to protect the machine from con-

struction dirt and moisture before installation. Also, do not

remove protective shipping cover on control panel until ready

to use.

Step 2 — Rigging and Installation

PREPARING 2-PIECE UNIT — Two-piece units must be

prepared for installation before they can be rigged.

1. Open auxiliary evacuation valve to break vacuum in

absorber-evaporator shell.

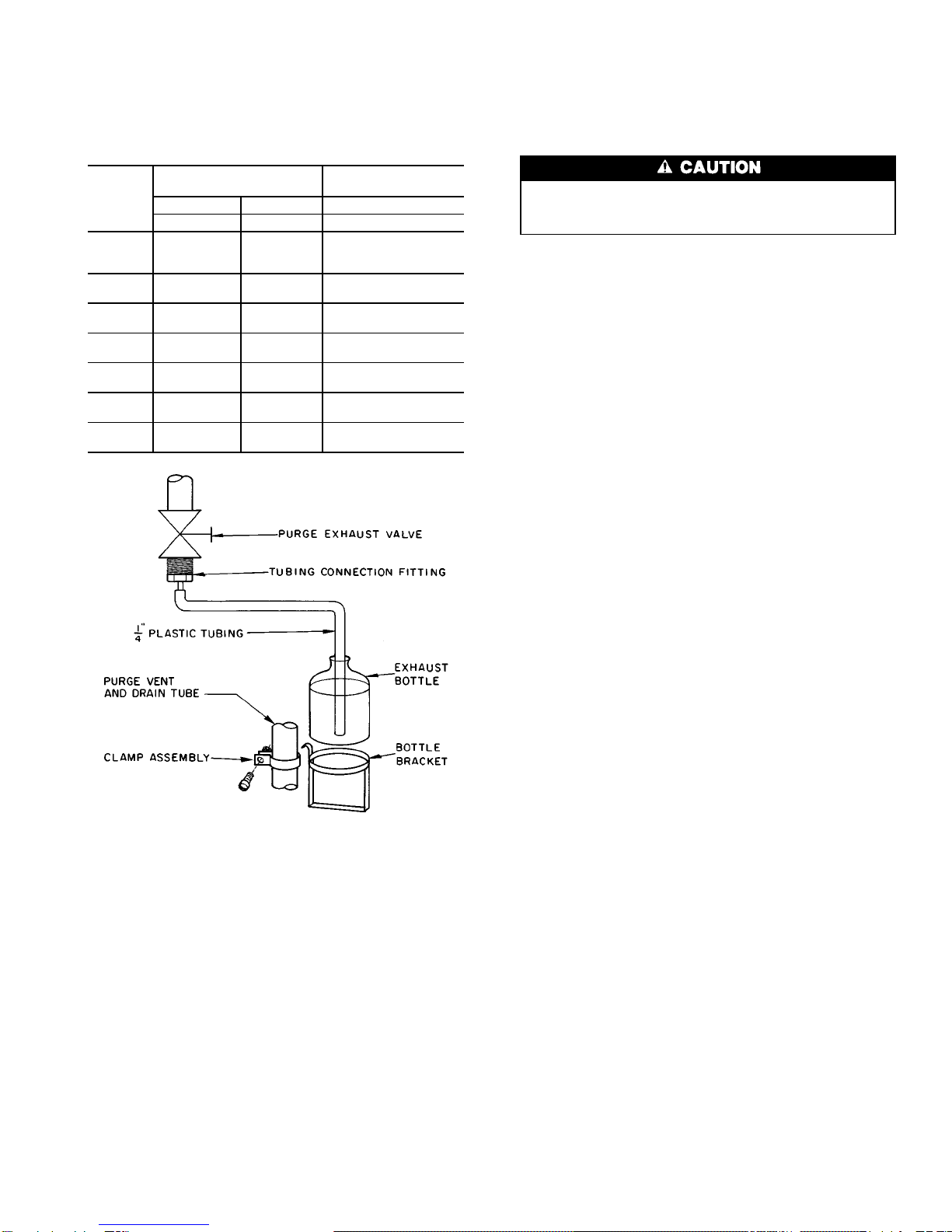

2. Open shipping valve (Fig. 2) on generator-condenser

assembly.

3. Protect machine insulation with a leather or wet canvas

cover when welding or cutting.

4. Remove all piping end plates as shown in Fig. 2.

5. Remove the weld elbow and shipping valve on the

condenser-purge suction line.

To avoid contaminates and debris getting into chiller,

do not leave machine open any longer than necessary.

Be careful not to remove any stock from pipe ends. Do

not get slag inside machine while flame cutting.

RIG MACHINE PROPERLY — Refer to rigging instruc-

tions in plastic envelope attached to machine. Rigging in-

structions vary for one-piece units and 2-piece units.

Lifting machine from points other than those specified

may result in serious damage and personal injury. Rig-

ging equipment and procedure must be adequate for ma-

chine weight. Refer to Table 2 for machine weights.

Table 2 — Rigging Weights

UNIT

16JB WEIGHT (lb) WEIGHT (kg)

1-PIECE UNITS

010 9,000 4,082

012 9,100 4,128

014 9,100 4,128

018 11,500 5,216

021 12,300 5,579

024 14,600 6,622

028 14,800 6,713

032 18,500 8,391

036 18,900 8,573

041 23,000 10,433

047 23,500 10,659

2-PIECE UNITS

Absorber Generator Absorber Generator

041 18,000 5,500 8,165 2,495

047 18,500 5,500 8,392 2,495

054 21,500 7,000 9,752 3,175

057 22,000 7,000 9,979 3,175

061 26,500 7,000 12,020 3,175

068 28,000 7,400 12,701 3,357

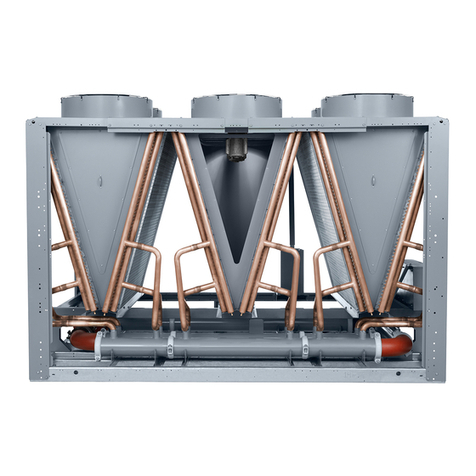

Rigging One-Piece Units — One-piece units consist of all

units from 010-036 and, when specified, units 041-047. Lift

with cable slings under condenser water boxes. Refer to Fig. 1.

Fig. 2 — Weld Breaking Instructions

3