Installation & Operation Instructions

These instructions include information which is intended

to assure the operator of correct installation, operation,

and service. Before attempting installation, adjustment

or maintenance, be certain of the following:

1.That you have read and fully understand the instruc-

tions.

2.That you have all the tools required and are trained to

use them.

3.That you have met all installation and usage restric-

tions and are familiar with the functions and operation

of the unit.

4.That you follow all instructions exactly as given.

All fittings, measurements, procedures and recommen-

dations are significant. Substitutions and approximation

must be avoided. Improper handling, maintenance,

installation and adjustment or service attempted by any-

one other than a qualified technician, may void the

future warranty claims and cause damage to the unit

and/or result in injury to the operator and/or bystanders.

Record for Service

Model No. __________________________________

Serial No.____________________________________

Installation Date ______________________________

Invoice Date__________________________________

Start-up Date ________________________________

Telephone for Service __________________________

INSTALLATION INSTRUCTIONS

Thermostat will maintain approximately zero degrees on

the original factory setting. Turn the adjusting screw

clockwise for colder and counterclockwise for warmer.

IMPORTANT: Turning control counterclockwise to the

stop shuts cabinet "OFF".

For storage of package ice cream, turn thermostat to

coldest position. Limit top layer of package to a height

consistent with cabinet usage and turn over of product.

LOCATION

Select a location for the cabinet which will be most con-

venient for the customer and which will allow adequate

air circulation.Restricted air flow will result in higher con-

densing pressures and operating costs.

Provide at least a 1-inch space around the exterior of

the cabinet. The outside shell is the condenser and

depends on the natural convection of room air for dissi-

pation of its heat. Stainless or formica facing sheets

applied to the cabinet exterior should be in tight contact

with the cabinet's outer walls to improve the heat flow.

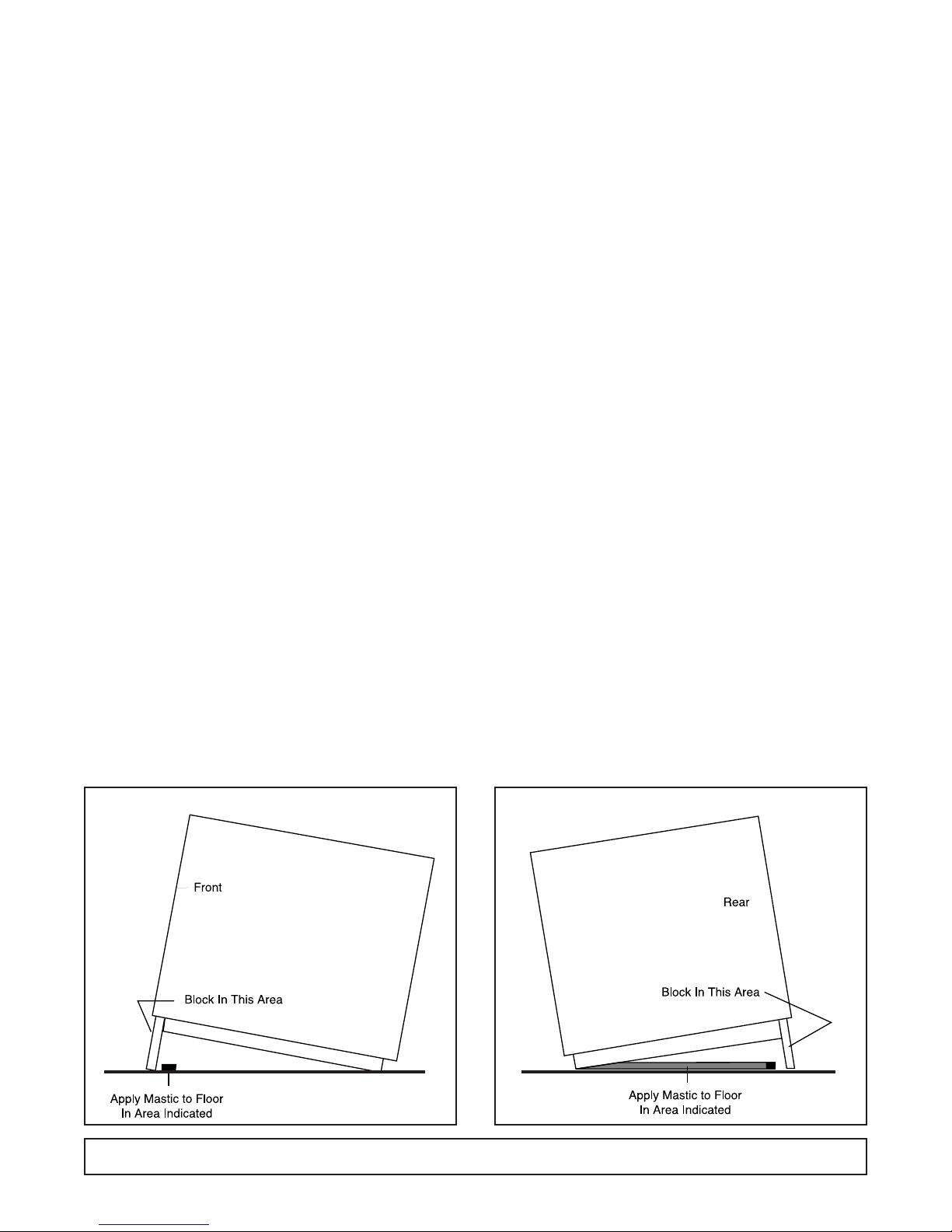

When a cabinet is built into a counter or back-bar and

space is allowed between the counter and the cabinet

walls, provide holes or louvers along the top edge for hot

air to escape.Holes should be screened to keep insects

and rodents out.

IMPORTANT: Before building any piece of equipment

in, run it to be sure the operation is satisfactory.

BE SAFE. SEE ILLUSTRATION ABOVE.

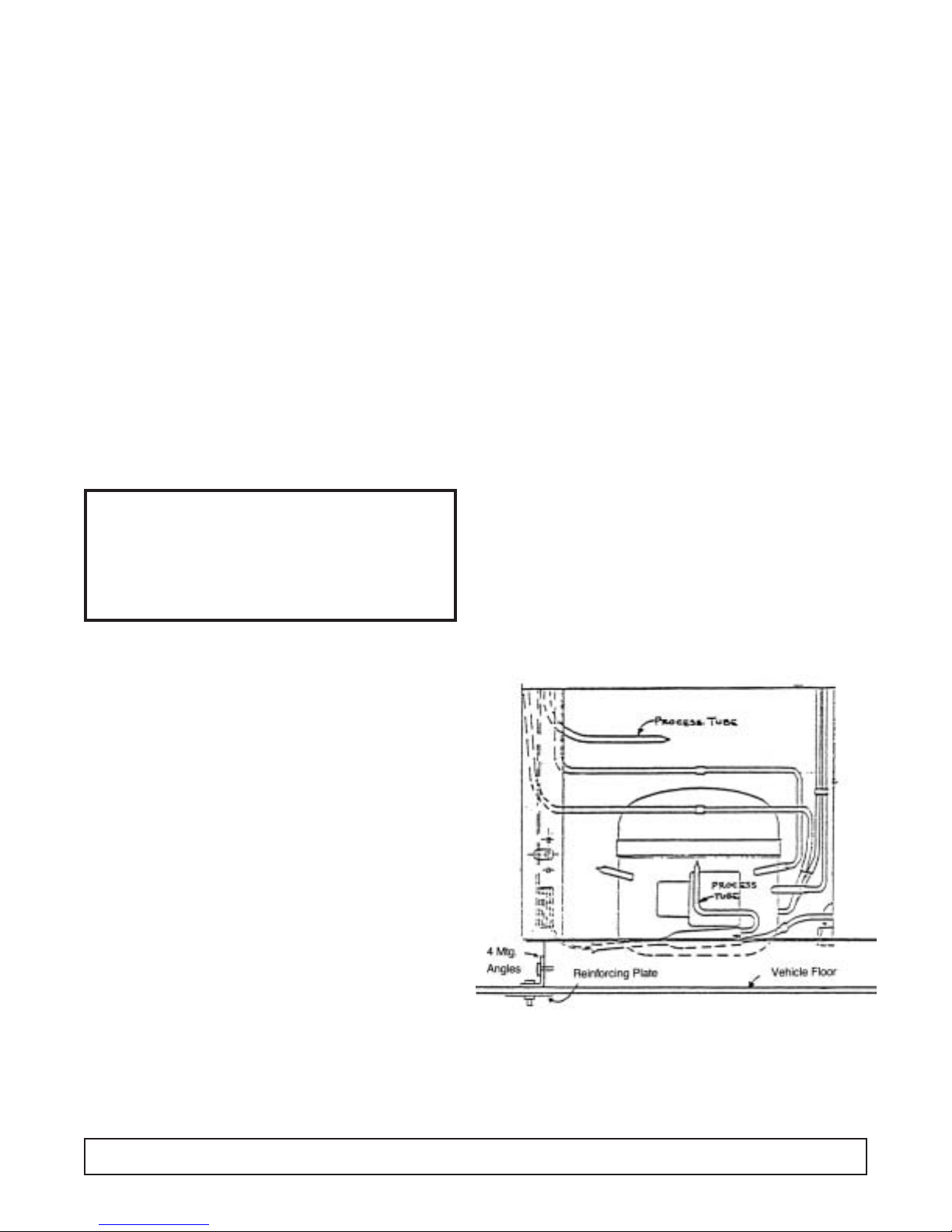

When a cabinet is installed in a moving vehicle, use the

original crate mounting angles or equivalent to securely

bolt the cabinet to the vehicle floor so it won't move

going around corners or during sudden starts and stops.

INSTALLATION & OPERATION 3

Important information is contained in

these instructions which should be

retained in a convenient location for

future reference.