2

• FAN SPEED CONTROL - DURING HEATING

• FAN SPEED CONTROL - DURING COOLING

• MODULATING WATER ECONOMIZER CONTROL

• TWO-POSITION WATER ECONOMIZER CONTROL

• POWER FAIL RESTART DELAY

• SUPPLY AIR TEMPERATURE MONITORING/

CONTROL/ ALARM

• DEHUMIDIFICATION

• SPACE TEMPERATURE ALARMS

• CONDENSER WATER TEMPERATURE

MONITORING/CONTROL/ALARM

• HIGH CONDENSATE / OVERFLOW ALARM

• FILTER STATUS ALARM

• COMPRESSOR FAULT/LOCKOUT ALARM

• INSUFFICIENT VENTILATION ALARM

• RELATIVE HUMIDITY ALARM

• TIME SCHEDULES

• HOLIDAY SCHEDULES

• OVERRIDE SCHEDULES

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Water Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Condensate Drain Pans . . . . . . . . . . . . . . . . . . . . . . 58

Refrigerant System . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Fan Motor Lubrication . . . . . . . . . . . . . . . . . . . . . . . . 58

Fan Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . 58

Condensate Drain Cleaning . . . . . . . . . . . . . . . . . . . 58

Air Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Condenser Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 58

• GRAVITY FLOW METHOD

• FORCED CIRCULATION METHOD

Checking System Charge . . . . . . . . . . . . . . . . . . . . . 59

Refrigerant Charging . . . . . . . . . . . . . . . . . . . . . . . . . 59

Air Coil Fan Motor Removal . . . . . . . . . . . . . . . . . . . 59

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . 60

• UNIT PROTECTION MODULE (UPM)

Freeze Protection Sensors . . . . . . . . . . . . . . . . . . . . 62

Thermostatic Expansion Valves . . . . . . . . . . . . . . . 62

• TXV FAILURE

SAFETY CONSIDERATIONS

Installation and servicing of air-conditioning equipment can be

hazardous due to system pressure and electrical components. Only

trained and qualified service personnel should install, repair, or

service air-conditioning equipment.

Untrained personnel can perform basic maintenance functions of

cleaning coils and filters and replacing filters. All other operations

should be performed by trained service personnel. When working

on air-conditioning equipment, observe precautions in the

literature, tags and labels attached to the unit, and other safety

precautions that may apply.

Improper installation, adjustment, alteration, service,

maintenance, or use can cause explosion, fire, electrical shock or

other conditions which may cause personal injury or property

damage. Consult a qualified installer, service agency, or your

distributor or branch for information or assistance. The qualified

installer or agency must use factory-authorized kits or accessories

when servicing or repairing this product. Refer to the individual

instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions attached to the unit. Consult local building

codes and the National Electrical Code (NEC) for special

installation requirements.

Understand the signal words — DANGER, WARNING, and

CAUTION. DANGER identifies the most serious hazards which

will result in severe personal injury or death. WARNING signifies

hazards that could result in personal injury or death. CAUTION is

used to identify unsafe practices, which would result in minor

personal injury or product and property damage.

It is important to recognize safety information. This is the safety-

alert symbol . When you see this symbol on the unit and in

instructions or manuals, be alert to the potential for personal

injury.

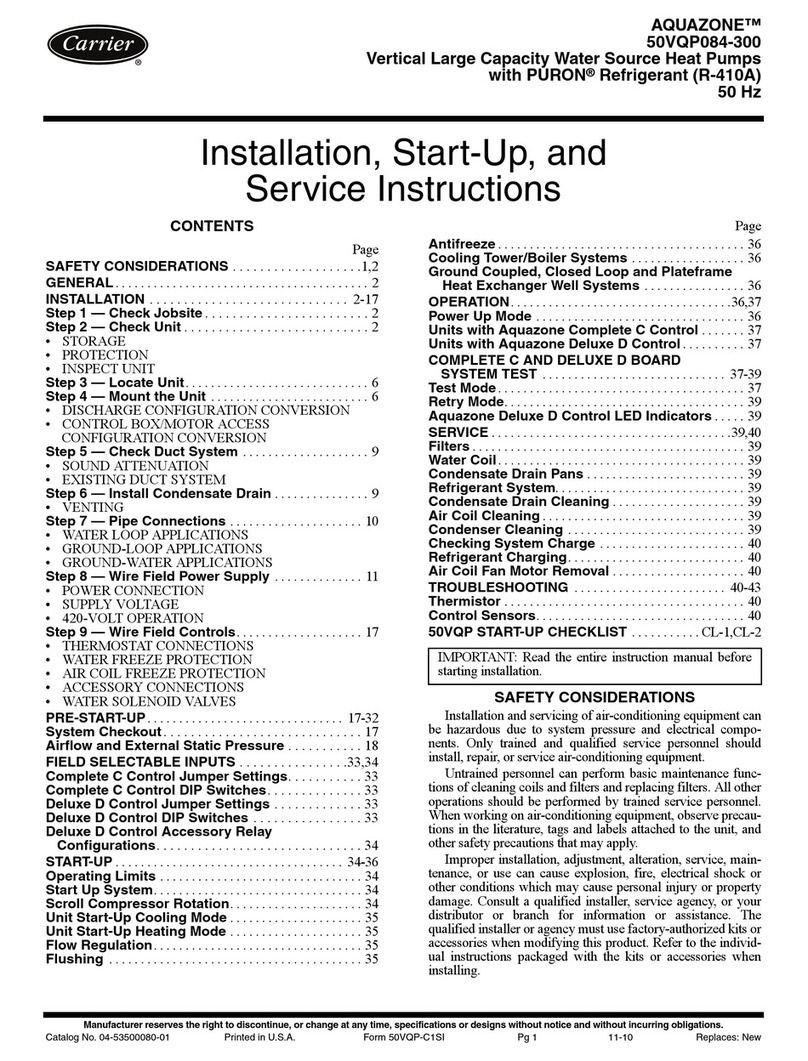

GENERAL

This Installation and Start-Up Instructions literature is for

Aquazone™ water source heat pump systems.

Water source heat pumps (WSHPs) are single-package vertically

or horizontally mounted units with a reversible refrigeration cy-

cle for year-round cooling and heating.

PRE-INSTALLATION

INSPECTION

Upon receipt of shipment, carefully check the shipment against

the bill of lading. Make sure all units have been received. Inspect

the carton or crating of each unit, and inspect each unit for damage

on both the interior and exterior. Ensure the shipping company

makes proper notation of any shortages or damage on all copies of

the freight bill. Concealed damage not discovered during unload-

ing must be reported to the shipping company within 5 days of re-

ceipt of shipment.

NOTE: It is the responsibility of the purchaser to file all necessary

claims with the shipping company.

STORAGE

IMPORTANT: Read the entire instruction manual before

starting installation.

WARNING

Electrical shock can cause personal injury and death. Shut off

all power to this equipment during installation and service.

There may be more than one disconnect switch. Tag all

disconnect locations to alert others not to restore power until

work is completed.

IMPORTANT: The installation of water source heat pump units

and all associated components, parts, and accessories which

make up the installation shall be in accordance with the

regulations of ALL authorities having jurisdiction and MUST

conform to all applicable codes. It is the responsibility of the

installing contractor to determine and comply with ALL

applicable codes and regulations.

CAUTION

EQUIPMENT DAMAGE HAZARD

DO NOT store or install units in corrosive environments or in

locations subject to temperature or humidity extremes (e.g., at-

tics, garages, rooftops, etc.). Corrosive conditions and high

temperature or humidity can significantly reduce performance,

reliability, and service life. Always move units in an upright

position. Tilting units on their sides may cause equipment

damage.