CONTENTS

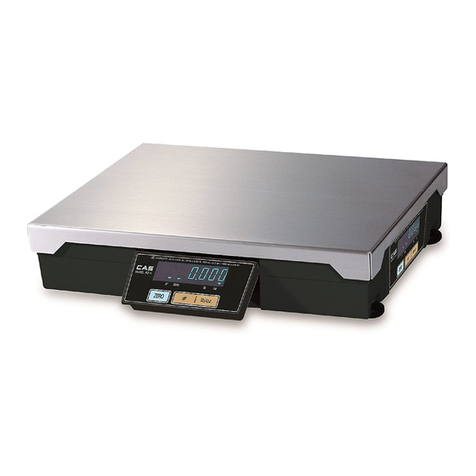

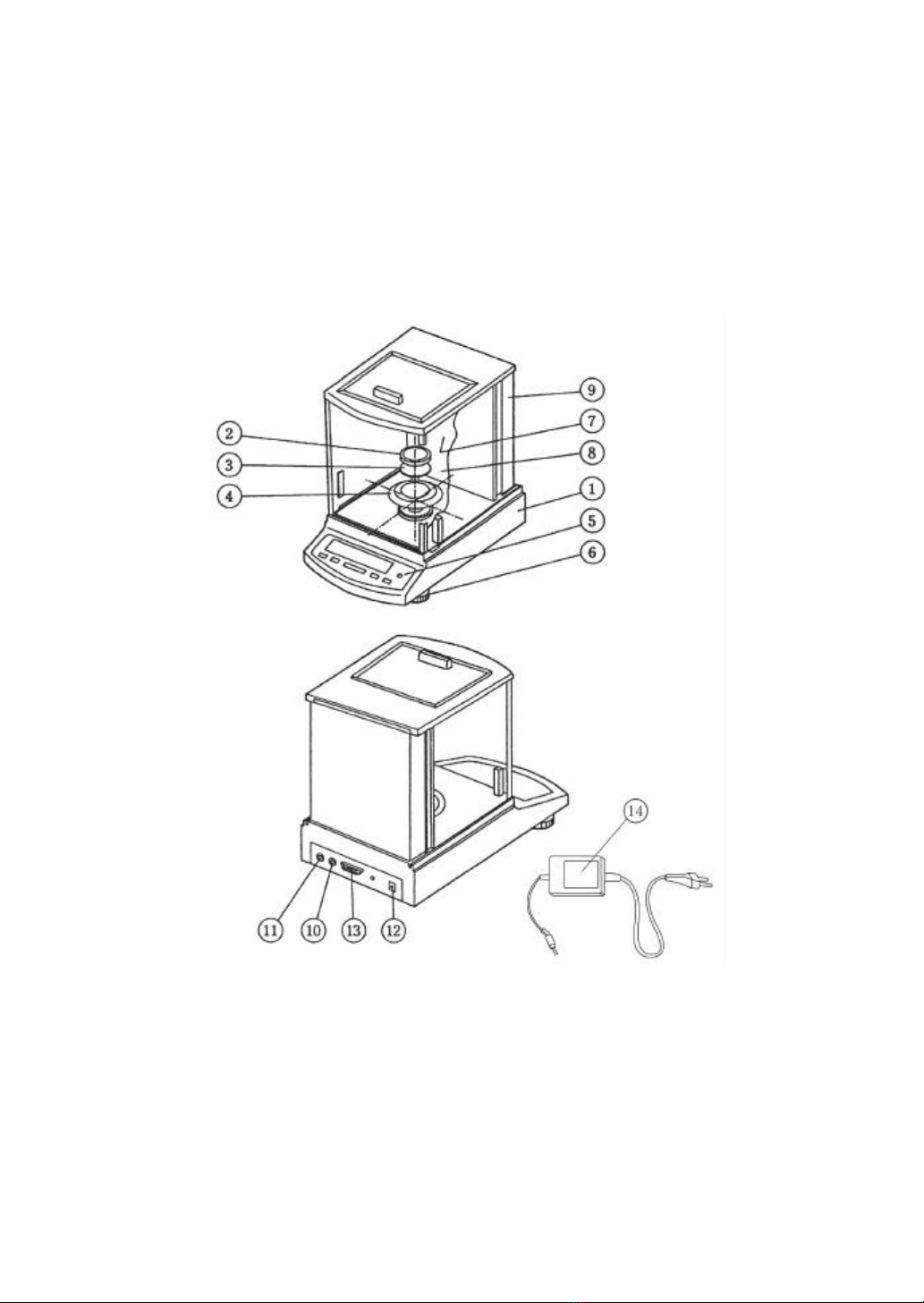

1. BALANCE COMPONENTS.................................................................................1

2. INSTALLATION..................................................................................................5

3. WARM-UP..........................................................................................................6

4. PRECAUTIONS..................................................................................................6

5. MEASUREMENT PROCEDURE.........................................................................7

6. MENU SELECTION............................................................................................7

6.1 OPERATION MENU...........................................................................................8

6.2 FUNC.SEL MENU.........................................................................................10

6.3 SETTING MENU ............................................................................................12

6.4 INTFACE MENU............................................................................................16

6.5 UNIT.SEL MENU ...........................................................................................18

6.6 IF:USER MENU.............................................................................................20

7. SPAN CALIBRATION (SENSITIVITY ADJUSTMENT).......................................22

7.1 SPAN CALIBRATION USING THE BUILT-IN WEIGHT.............................................22

7.2 SPAN CALIBRATION USING AN EXTERNAL WEIGHT ...........................................23

7.3 SPAN CHECK USING THE BUILT-IN WEIGHT......................................................24

7.4 SPAN CHECK USING AN EXTERNAL WEIGHT ....................................................25

8. ZERO TRACKING ............................................................................................26

9. STABILITY DETECTION BAND ........................................................................26

10. REGISTRATION, RELEASE, AND SELECTION OF MEASURE-MENT UNITS .26

10.1 PERCENTAGE................................................................................................27

10.2 NUMBER OF PIECES.......................................................................................28

10.3 SOLID SPECIFIC GRAVITY...............................................................................29

10.4 LIQUID SPECIFIC GRAVITY..............................................................................30

11. AUTO PRINT ....................................................................................................31

12. ANALOG DISPLAY...........................................................................................31

13. ADD LOAD WEIGHING ....................................................................................32

14. STANDARD SPAN CALIBRATION (SENSITIVITY ADJUSTMENT)...................33

15. EXTERNAL WEIGHT VALUE FOR SPAN CALIBRATION.................................34

16. EXTERNAL WEIGHT VALUE FOR BUILT-IN WEIGHT CALIBRATION

(CAW/CAX SERIES ONLY) ..............................................................................34